Rack structure capable of saving lubricating oil for reciprocating pump

A rack structure and reciprocating pump technology, which is applied to components, pump elements, mechanical equipment, etc. of pumping devices for elastic fluids, and can solve problems such as short service time, high viscosity value requirements, and low speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] The embodiments of the present invention are not limited to the following examples, and various changes made without departing from the gist of the present invention fall within the protection scope of the present invention.

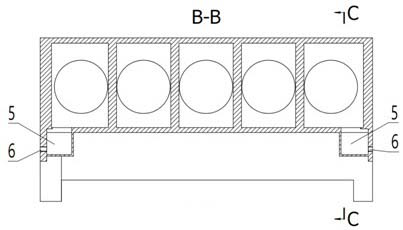

[0021] see Figure 1 to Figure 6 , the present embodiment is a rack structure for reciprocating pumps to save the amount of lubricating oil, including a crankshaft chamber 1, a crosshead chamber 2, a bottom surface of the crankshaft chamber 3, a bottom surface of the crosshead chamber 4, a water precipitation chamber 5, a drain port 6, and an improved crankshaft Cavity bottom 7, improved crosshead cavity bottom 8, oil return cavity 9, crankshaft cavity 10, crosshead cavity 11, connecting rod 12, crankshaft cavity bottom 13, crosshead cavity bottom 14, base 15, rolling bearing 16, large gear 17 , 18 rolling bearing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com