Biological oil-displacing agent welan gum and oil-displacing system thereof

A technology of biological flooding and welan gum, applied in the direction of microorganisms, methods based on microorganisms, biochemical equipment and methods, etc., to achieve the effects of simple preparation process, reduced dosage and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 welan gum fermentation liquid flooding system

[0040] Inoculate the frozen sphingomonas Sphingomonas sp.WG with the preservation number M2013161 in the primary seed medium, and cultivate it at 30°C and 150r / min for 16-24 hours to obtain the primary seed liquid; According to the volume ratio of 1: (15-20) the inoculum is inoculated into the secondary seed medium, and cultivated at 30°C and 150r / min for 16-18 hours to obtain the secondary seed liquid. Inoculate the secondary seed liquid into 20 times the volume of fermentation medium, and cultivate it at 30°C and 150r / min for 24-72 hours to obtain a welan gum fermentation liquid; wherein, the primary seed medium and the secondary seed culture The base is a medium containing 8-12g / L sucrose, 0.5-1g / L yeast extract, 2-8g / L peptone, 1-2g / L potassium dihydrogen phosphate and 0.5-1g / L magnesium sulfate; fermentation culture The base is a culture medium containing 60-80g / L sucrose, 2-5g / L yeast extract, 2-5g / L di...

Embodiment 2

[0046] Embodiment 2 welan gum aqueous solution flooding system

[0047] The fermented liquid of Welan gum obtained in Example 1 was processed through alcohol precipitation and dried for 24-72 hours to obtain the crude product Welan gum; the crude product Welan gum was used in isopropanol / sodium chloride system (the concentration of sodium chloride 2-5%), further purified, dried for 24-72 hours, and ground into powder to obtain the biological oil displacement agent welan gum.

[0048] Prepare the obtained bio-displacing agent welan gum into an aqueous solution with a concentration of 0.03-0.05%, stir evenly in a water bath at 35-40°C, let it stand overnight at room temperature, and use a six-speed rotary viscometer to measure the viscosity in the range of 25-100mPa Between .s, the welan gum aqueous solution flooding system was obtained and stored at 4°C.

[0049] Using the displacement simulation experiment as described in Example 1, the sand-packed pipe has a permeability of ...

Embodiment 3

[0051] Example 3 Welan gum fermentation broth-polymer compound oil displacement system

[0052] After diluting the welan gum fermentation liquid obtained in Example 1 by 2-5 times, polyacrylamide was added to the welan gum fermentation liquid until the polyacrylamide concentration reached 0.05%, and the viscosity range measured by a six-speed rotational viscometer was 120- 200mPa.s to obtain the welan gum fermentation broth-polymer compound oil displacement system, which was stored at 4°C.

[0053] Using the displacement simulation experiment as described in Example 1, the sand-packed pipe has a permeability of 3709mD and an oil-bearing volume of 138cm 3 , with a pore volume of 177cm 3 , the porosity is 35.7%. The simulated oil sample is mixed oil, the composition of which is crude oil: neutral kerosene = 1:1, and the viscosity is 300mPa.s.

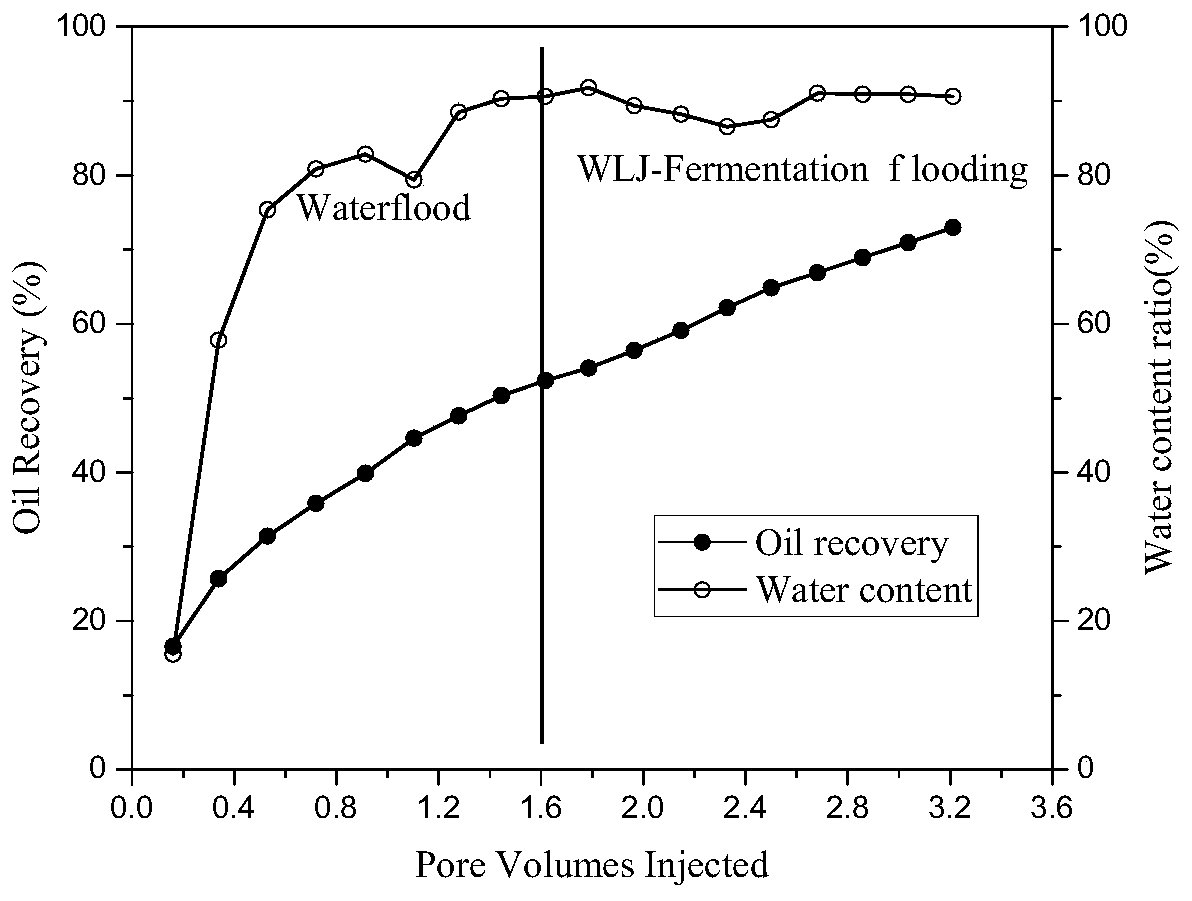

[0054] A total of 3.2PV of displacement fluid was measured, including 1.6PV for water flooding and 1.6PV for chemical flooding. disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com