Viscometer

A technology of viscosity and viscometer, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of bending shape of flow tube, impracticability for users, and inability to fully reduce the error of viscosity measurement value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

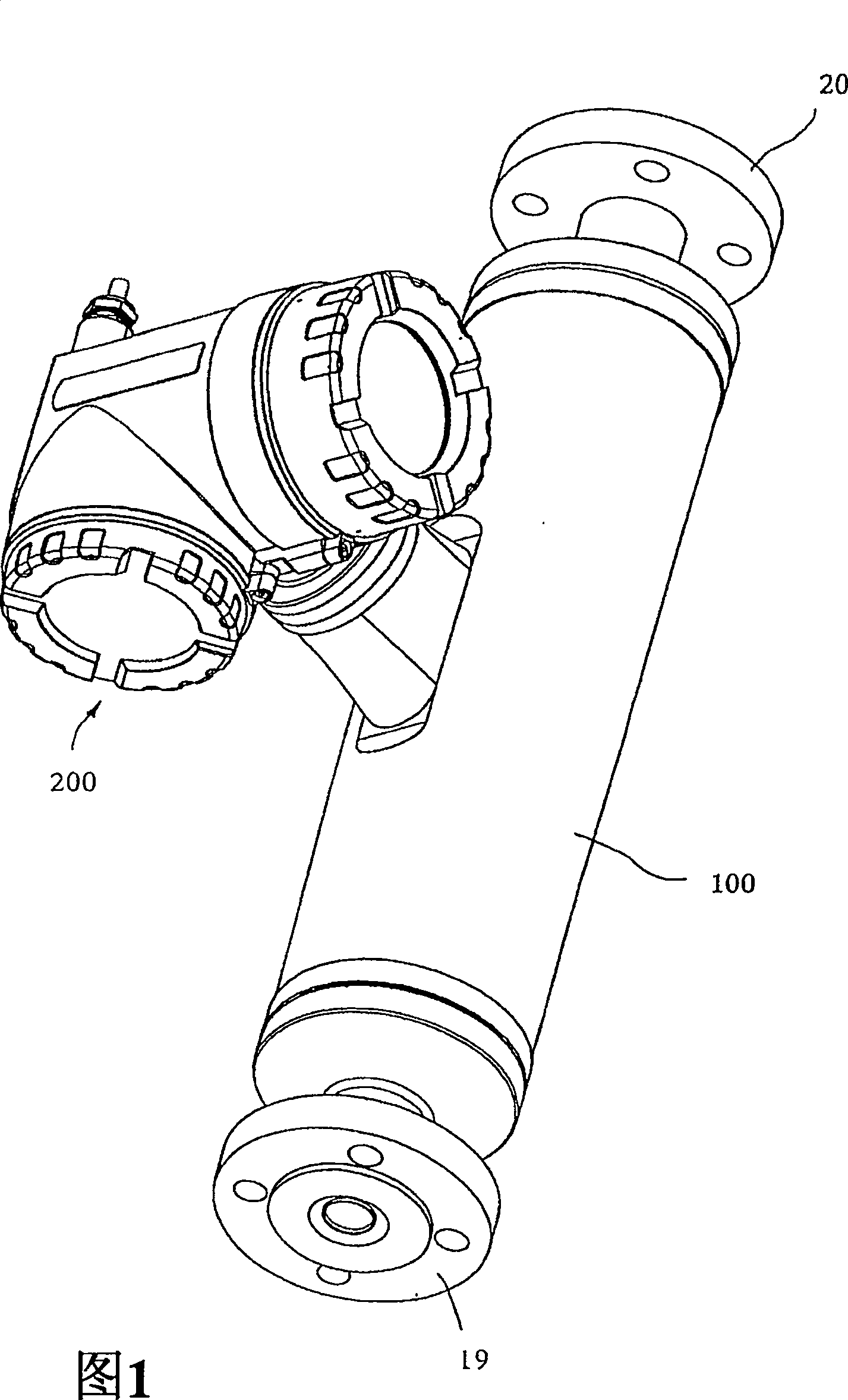

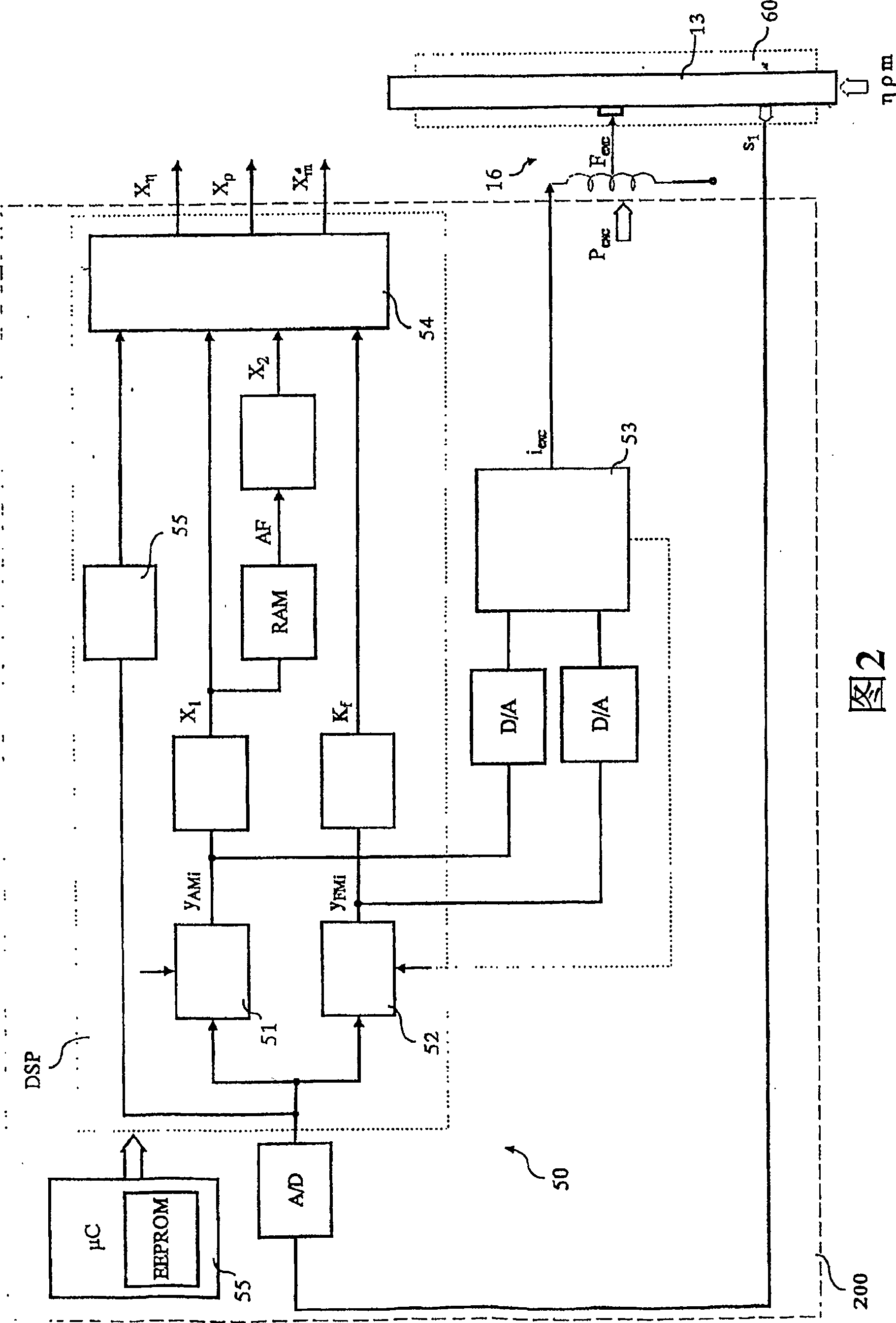

[0068] FIG. 1 schematically shows a viscometer having a vibration sensor 10 preferably housed in a sensor box 100 and electronic measuring equipment 50 housed in an electronics box 200, and as shown in FIG. Shown, and the sensor 10 is electrically connected. The viscometer is used in particular to sense the viscosity η of a fluid flowing in a pipe (not shown) and to map this viscosity to a viscosity measurement X representing this viscosity η η . With the sensor 10 driven by the electronic measuring device 50, a frictional force is generated in the fluid therein, which is related to the viscosity η and acts on the sensor 10 in a measurable manner, i.e. this frictional force can be detected and converted using sensor technology Useful input signal for subsequent electronic evaluation equipment.

[0069] In the preferred case where the viscometer is designed to be connected to a fieldbus, it is preferred that the programmable electronics measuring device 50 include a suitable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com