A kind of low-temperature molding resin carbon plate and preparation method thereof

A technology of resin carbon and low temperature, which is applied in the field of low temperature forming resin carbon plate and its preparation, can solve the problems of complicated process and high cost, and achieve the effects of high conductivity, adjustable mechanical strength and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Application of fuel cell graphite bipolar plate

[0020] By weight percentage, 30% novolac epoxy resin, 15% alkyd resin, 5% resin hardener, 35% graphite powder (particle size 0.05mm), 5% carbon powder (particle size <0.001mm)+ 5% zinc hydroxide + 5% aluminum oxide were mixed evenly, and poured into a mold after standing for 30 minutes at a temperature of 250°C and a pressure of 20MPa. After 30 minutes, the mold was opened, taken out and left to cool.

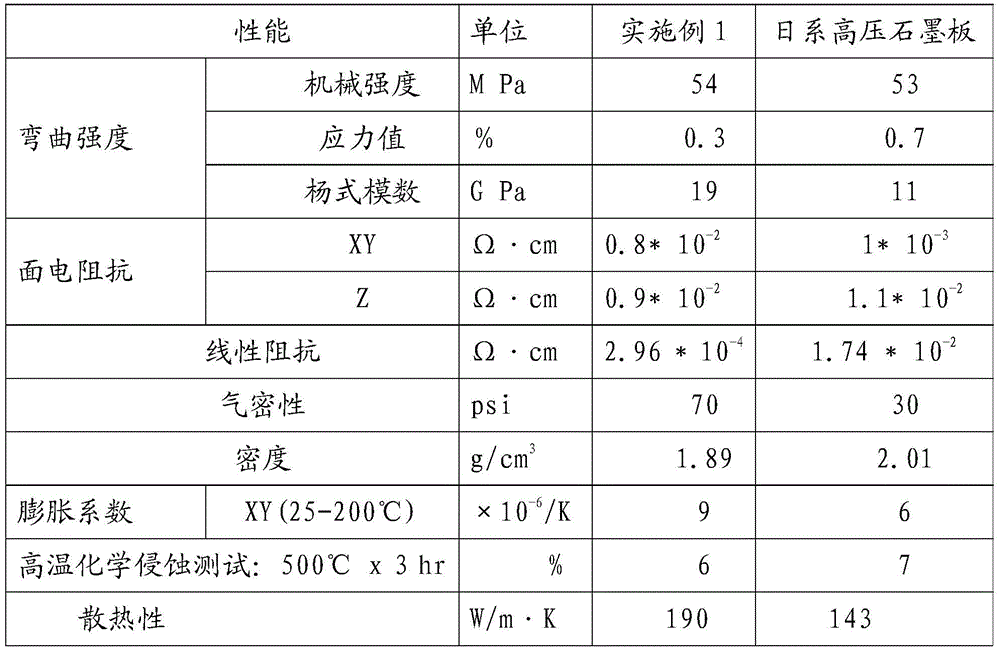

[0021] Table 1 Simultaneous Conductivity Test

[0022]

[0023] It can be obtained from Table 1:

[0024] 1. In terms of mechanical strength, there is no significant difference between the carbon plate in Example 1 and the commercially available Japanese high-pressure graphite plate;

[0025] 2. Stress value <1% (maximum deformation before reaching plate bending);

[0026] 3. In this embodiment, the Young's modulus of the carbon plate is higher than that of the graphite plate, and the larger the value, the smalle...

Embodiment 2

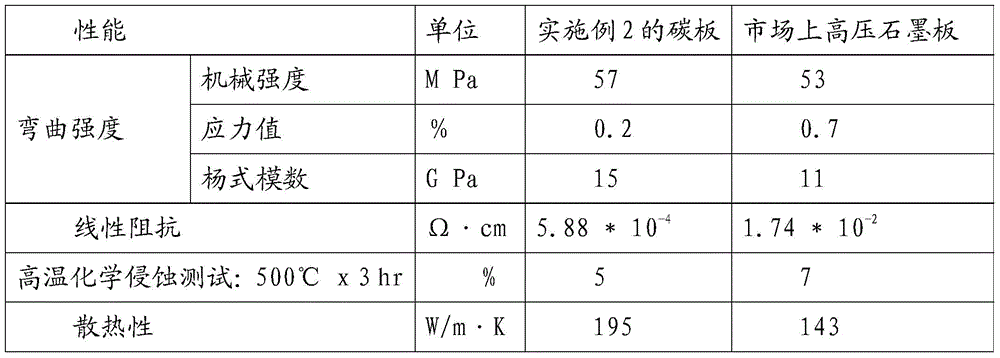

[0032] Example 2: Application of carbon plate for high conductivity electrode of lithium polymer battery

[0033] Percentage by weight, 20% novolak epoxy resin, 15% polyester resin, 40% graphite powder (0.05mm particle size), 5% titanium oxide (0.003mm particle size), 5% zinc oxide, 5% Mix the nano-silver wire and 10% alumina powder evenly, pour it into the mold after standing for 30 minutes, the temperature is 250°C, the pressure is 20MPa, the time is 30 minutes→open the mold, take it out, let it stand and cool, and then bake at 900°C for 1 hour.

[0034] Table 2

[0035]

Embodiment 3

[0037] Step A: mix 5% carbon powder and 20% carbon nanotubes uniformly by weight percentage, then add 10% zinc hydroxide and 20% titanium oxide, and mix uniformly with a dry powder homogenizer;

[0038] Step B: uniformly mix the uniformly mixed material obtained in step A with 45% polyester resin, and let it stand for 1 hour to make the mixing balanced;

[0039] Step C: Take the complete material and pour it into the mold with the designed gas flow channel to release the film. After the film is removed, the required resin carbon plate can be obtained. The conditions are: set the temperature at 100°C, set the pressure at 100MPa, and set the time for 3 minutes;

[0040] Step D: Put the obtained resin carbon plate in an oven at 500°C and bake for 30 minutes.

[0041] table 3

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com