Annular glass surrounded glass-blown miniature hemispherical resonant gyroscope and manufacturing method thereof

A technology of hemispherical resonant gyroscope and glass, which is applied in the direction of steering sensing equipment, etc., can solve the problems of restricting the development and application of micro hemispherical resonant gyroscope, and the low level of micromachining technology, and achieve the effect of high rigidity, good impact resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] like Figure 1-2 As shown, the present embodiment provides a ring-shaped glass-enclosed glass-blown micro-hemispherical resonator gyroscope, including:

[0038] A cuboid silicon substrate 1;

[0039] A hemispherical shell-type central harmonic oscillator 2;

[0040] Eight metal electrodes made on the ring-shaped glass shell 3, including four driving electrodes and four detecting electrodes, are connected to pin 10 through leads; the four driving electrodes are not in contact with the hemispherical shell-type central resonator 2 , the four detection electrodes are not in contact with the hemispherical shell-type central resonator 2, and the spatial positions of the four driving electrodes and the spatial positions of the four detection electrodes are sequentially distributed at intervals;

[0041] Both the hemispherical shell-type central resonator 2 and the ring-shaped glass shell 3 are formed by glass blowing. The hemispherical shell-type central resonator 2 is locat...

Embodiment 2

[0044] like Figure 3(a) ~ Figure 3(f) , the present embodiment provides a method for manufacturing an annular glass-enclosed glass-blown micro-hemispherical resonator gyroscope, comprising the following steps:

[0045] In the first step, as shown in FIG. 3(a), the single crystal cuboid silicon substrate 1 is cleaned;

[0046] In the second step, as shown in FIG. 3(b), the rectangular parallelepiped silicon substrate 1 is coated with glue, photolithography and developed to obtain a photoresist 6;

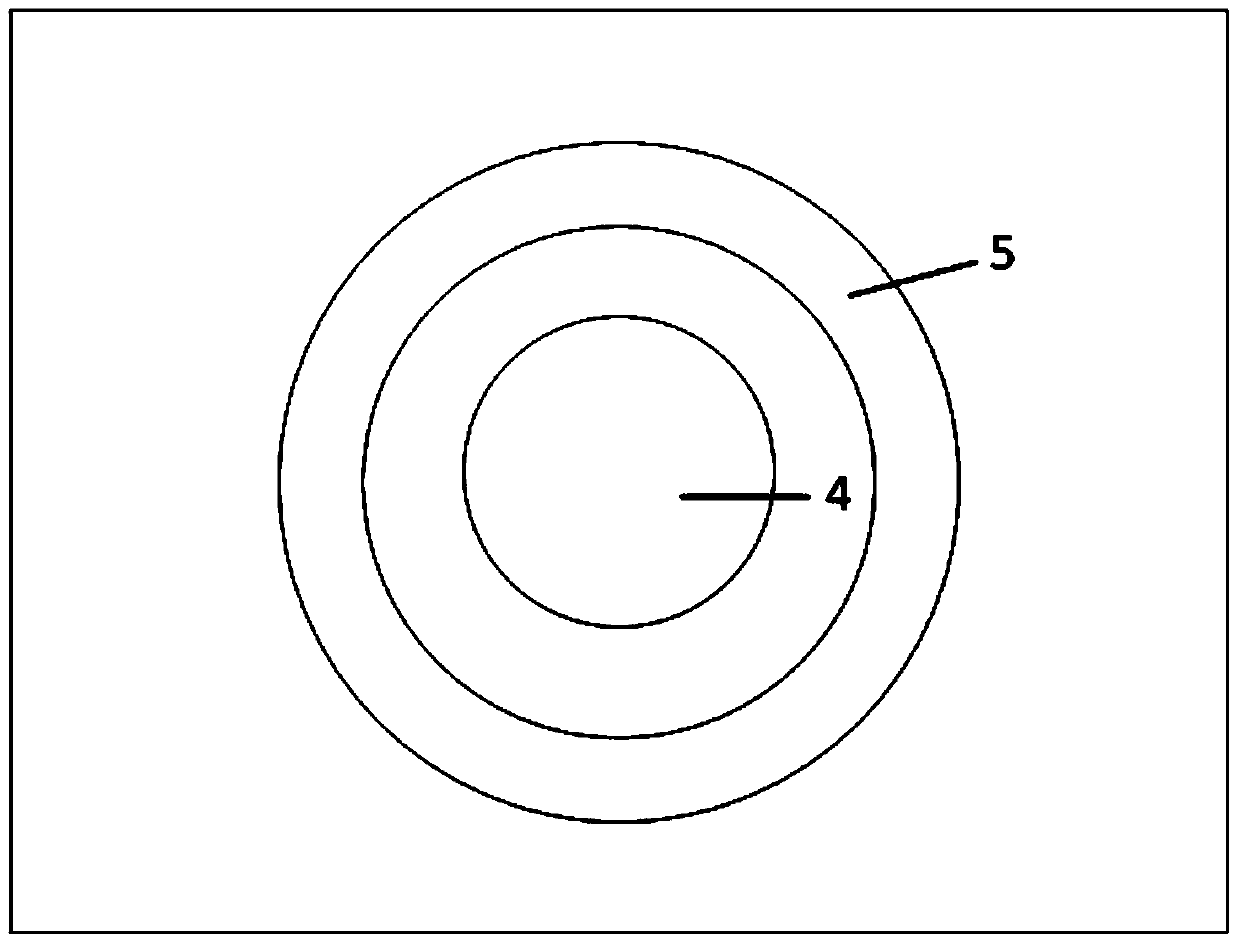

[0047] The third step, as shown in Figure 3(c), is to carry out ICP etching to the rectangular parallelepiped silicon substrate 1, and obtain a central circular groove 4 and a peripheral annular groove 5 after deglue, wherein, the peripheral annular groove 5 surrounds the central Circular groove 4 a week, and the outer edge 11 of central circular groove 4 and the inner edge of peripheral annular groove 5 keep a certain distance interval;

[0048] In the fourth step, as shown in FIG....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com