A method for constructing an aluminum alloy melting furnace with a high-nitrogen composite ceramic inner lining

A technology of high-nitrogen composite ceramics and lining layers, which is applied in the field of metal smelting facilities to achieve the effects of easy furnace cleaning, good quality, and metal corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

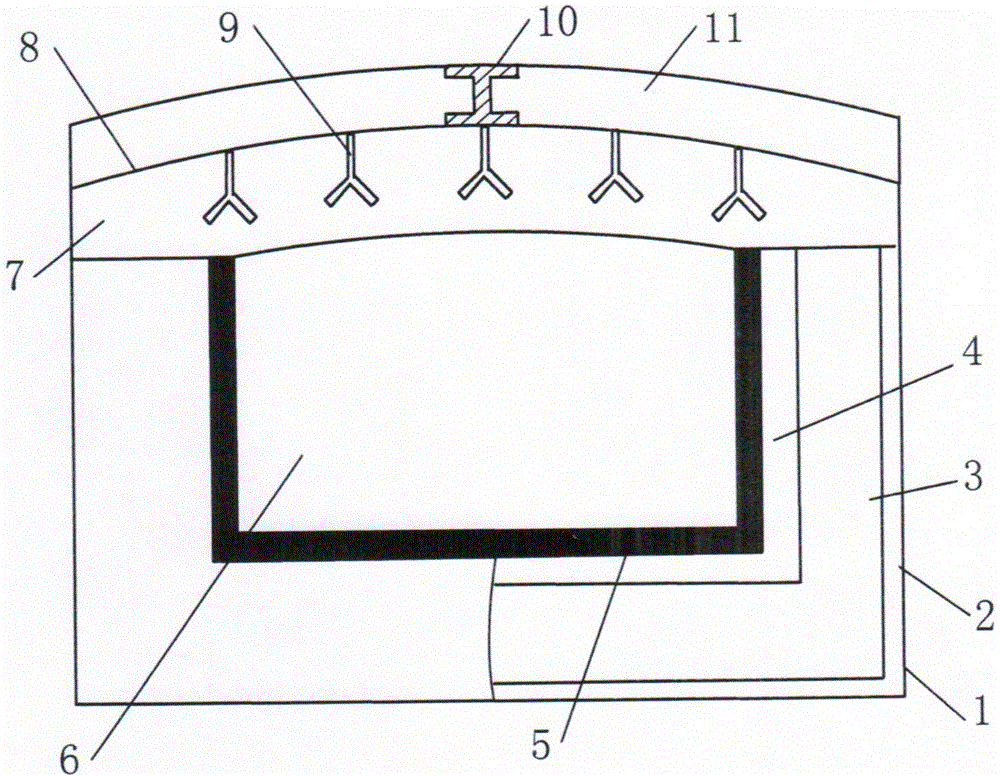

[0020] As shown in the figure,

[0021] There is a furnace chamber in the melting furnace, and structural parts and functional layers are arranged layer by layer outside the furnace chamber to construct the furnace body. The method of setting the functional layer and furnace body construction is as follows:

[0022] 1. Laying of aluminum silicate cotton felt layer 1: Use aluminum silicate heat insulation cotton felt to cling to the steel plate of the furnace body to form a veneer layer for the furnace body contour around and at the bottom of the furnace body;

[0023] 2. Laying of calcium-silicon lightweight insulation board layer 2: cast the insulation layer of calcium-silicon lightweight insulation board on the aluminum silicate cotton felt layer;

[0024] 3. Laying of the aluminum silicate insulation brick masonry layer 3: on the insulation layer of the calcium silicate light insulation board, use oxide ceramic cement to joint the masonry layer of the aluminum silicate insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com