Manufacturing method of tin-copper double-layer electroplated steel plates

A manufacturing method and technology for steel plates, which are applied in the field of manufacturing tin-copper double-layer electroplated steel plates, can solve the problems of poor welding performance of galvanized layers, affecting the processing performance and corrosion resistance of steel plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

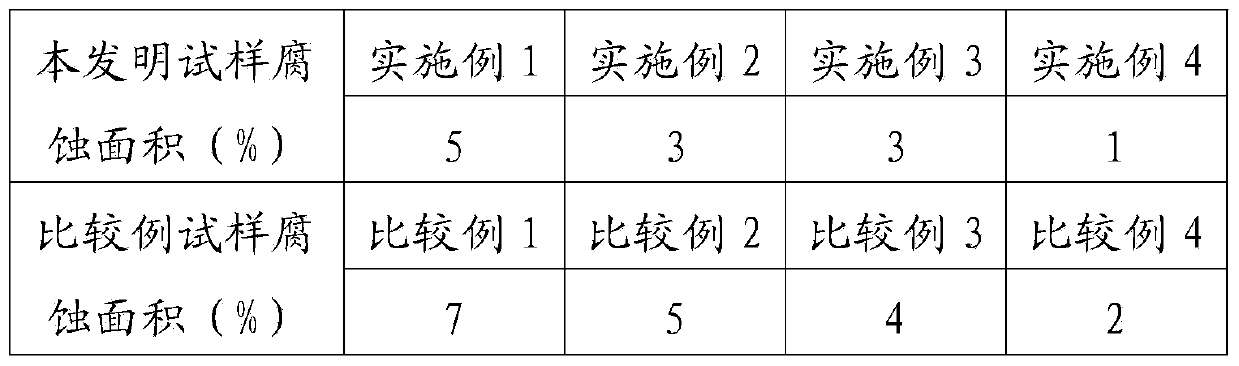

Examples

Embodiment 1

[0018] The ultra-thin cold-rolled steel sheet with a specification of 150×100×0.18mm is first derusted, washed, activated with dilute acid, and then dipped in nickel-containing solution. The formula of the nickel-impregnated solution is: nickel sulfate (NiSO 4 ·6H 2 O)): 30g / L, sodium hypophosphite (NaH 2 PO 2 ·H 2 O): 10g / L, sodium acetate (NaAc·3H 2 O) 10g / L, pH value: 4~6, temperature: 90°C, immersion nickel amount 30~50mg / m 2 , and then wash with water;

[0019] Copper is electroplated on the surface again, and the formula of electroplating copper solution is composed of: copper pyrophosphate (Cu 2 P 2 o 7 ): 65g / L, potassium pyrophosphate (K 4 P 2 o 7.. 3H 2 O): 230g / L, ammonia water: 2mL / L, DK-105 brightener 1mL / L, P 比 (P 2 o 7 4- / C u 2+ ):6.40~7.0, pH value 8.6~9.0, temperature: 50°C, cathode current density: 3A / dm2, anode: oxygen-free electrolytic copper plate, copper plating amount: 1.0 g / m2, copper plating will be finished with water After the surf...

Embodiment 2

[0021] The ultra-thin cold-rolled steel sheet with a specification of 150×100×0.25mm is first derusted, washed, activated with dilute acid, and then dipped in nickel-containing solution. 4 ·6H 2 O)): 30g / L, sodium hypophosphite (NaH 2 PO 2 ·H 2 O): 10g / L, sodium acetate (NaAc·3H 2 O) 10g / L, pH value: 4~6, temperature: 90°C, immersion nickel amount 30~50mg / m 2 , and then wash with water;

[0022] Copper is electroplated on the surface again, and the formula of electroplating copper solution is composed of: copper pyrophosphate (Cu 2 P 2 o 7 ): 95g / L, potassium pyrophosphate (K 4 P 2 o 7.. 3H 2 O): 280g / L, ammonia water: 3mL / L, DK-105 brightener 2mL / L, P 比 (P 2 o 7 4- / C u 2+ ):6.4~7.0, pH value 8.6~9.0, temperature: 55°C, cathode current density: 8A / dm2, anode: oxygen-free electrolytic copper plate, copper plating amount: 1.5g / m2, copper plating will be finished with water After the surface of the thin steel plate is cleaned, it is immediately put into an elec...

Embodiment 3

[0024] The ultra-thin cold-rolled steel sheet with a specification of 150×100×0.3mm is first derusted, cleaned, activated with dilute acid, and first dipped in nickel-containing solution. The formula of the nickel-impregnated solution is: nickel sulfate (NiSO 4 ·6H 2 O)): 30g / L, sodium hypophosphite (NaH 2 PO 2 ·H 2 O): 10g / L, sodium acetate (NaAc·3H 2 O) 10g / L, pH value: 4~6, temperature: 90°C, immersion nickel amount 30~50mg / m 2 , and then wash with water;

[0025] Copper is electroplated on the surface again, and the formula of electroplating copper solution is composed of: copper pyrophosphate (Cu 2 P 2 o 7 ) 105g / L, potassium pyrophosphate (K 4 P 2 o 7.. 3H 2 O): 370g / L, ammonia water: 5mL / L, DK-105 brightener 3mL / L, P 比 (P 2 o 7 4- / C u 2+ ):6.4~7.0, pH value 8.6~9.0, temperature: 60℃, cathode current density: 7A / dm2, anode: anaerobic electrolytic copper plate, copper plating amount: 2.5g / m2, copper plating will be finished with water After the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com