Method for preparing carbon-doped TiO2 film by using two-step method

A technology of thin film and step method, which is applied in the field of preparation of carbon-doped TiO2 thin film, and can solve problems such as corrosion and photocatalyst toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

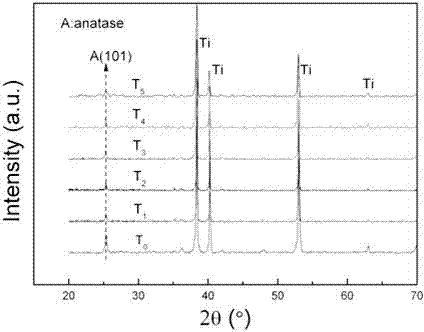

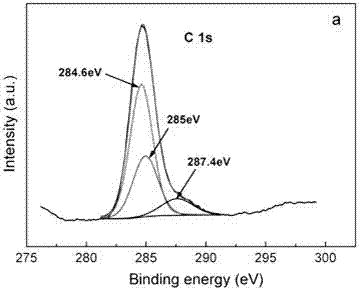

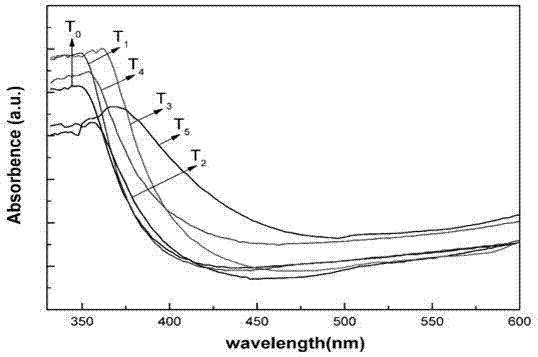

[0015] A two-step method for preparing carbon-doped TiO 2 Thin film method, the first step is to prepare TiO by magnetron sputtering 2 Thin film: place the processed glass, silicon wafer and titanium substrate, and use TiO 2 (99.9% purity) The ceramic target is a sputtering target, and the background vacuum is kept at 2×10 -3 Pa level, filled with argon gas with a purity of 99.999% and a certain amount of compensation oxygen (oxygen-argon ratio 1:143) during sputtering, sputtering power was 300 W, and sputtering time was 30 minutes. After sputtering, the substrate is covered with a layer of TiO with a thickness of about 100 nm. 2 film. Then keep it warm in the air at 500 ℃ for 2 hours, and then cool down naturally;

[0016] The second step is to implant C ions into TiO by ion implantation (PIII). 2 In the thin film: the annealed sample is placed in the ion implantation chamber, filled with CH 4 Gas, the working pressure is 1 Pa, the RF power is 40 W, the voltages are 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com