Single-component waterborne glass ink and preparation method thereof

A glass ink, one-component technology, applied in the field of ink, can solve the problems of unsatisfactory, water-based glass ink weather resistance, high temperature resistance and boiling resistance, etc., and achieve good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

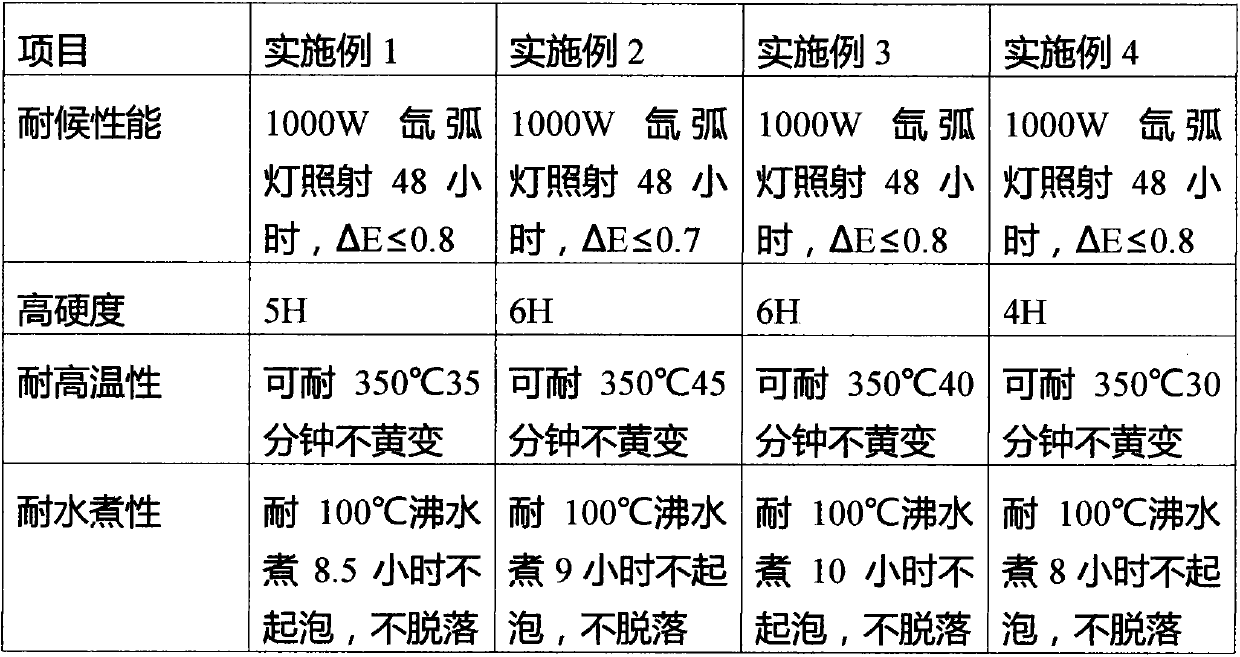

Examples

preparation example Construction

[0104] The invention provides a method for preparing the above-mentioned single-component water-based glass ink. The above-mentioned preparation method has a simple process and only needs two steps, and the raw materials are added sequentially according to a specific order and quantity. Moreover, the above-mentioned preparation method adopts simple equipment and low cost, and is suitable for large-scale industrial promotion and application.

[0105] Further, the above-mentioned preparation method adopts the specific formula of the present invention, which introduces water-based nano-inorganic silicate resin, so that the coating film has an inorganic coating (such as ceramics, enamel, enamel), generally high temperature resistance, high hardness, super weather resistance, and corrosion resistance. And it is very environmentally friendly; it also has the advantages of easy application of organic coatings, good flexibility, rich colors, strong applicability to glass substrates, an...

Embodiment 1

[0108] (1) Formulation:

[0109] Water-soluble acrylic resin: 25%

[0110] Water-based inorganic nano-silicate resin: 15%

[0111] Water-based amino resin: 32%

[0112] Dispersant: 1%

[0113] Water-based silicone defoamer: 1.5%

[0114] Leveling agent: 1%

[0115] Fumed silica: 1%

[0116] Silicone coupling agent: 2%

[0117] Polyethylene wax: 1.5%

[0118] Water-based pigments: 5%

[0119] Deionized water: 15%;

[0120] Wherein, the water-based inorganic nano-silicate resin is an inorganic nano-polymer polymer formed by 80% nano-scale silicate and 20% silica sol in an autoclave through water evaporation and the combination of intermolecular silicon-oxygen bonds, Its number average molecular weight is 10000-25000;

[0121] Described dispersant selects triethylhexyl phosphoric acid for use;

[0122] The leveling agent is selected from acrylate leveling agent;

[0123] The siloxane coupling agent is selected from bis-(γ-triethoxysilylpropyl) tetrasulfide;

[0124] ...

Embodiment 2

[0129] (2) Formulation:

[0130] Water-soluble acrylic resin: 40%

[0131] Water-based inorganic nano-silicate resin: 10%

[0132] Water-based amino resin: 20%

[0133] Dispersant: 0.5%

[0134] Water-based silicone defoamer: 0.5%

[0135] Leveling agent: 0.5%

[0136] Fumed silica: 0.5%

[0137] Silicone coupling agent: 1%

[0138] Polyethylene wax: 1%

[0139] Water-based pigments: 16%

[0140] Deionized water: 10%.

[0141] Wherein, the water-based inorganic nano-silicate resin is an inorganic nano-polymer polymer formed by 75% nano-scale silicate and 25% silica sol in an autoclave through water evaporation and the combination of intermolecular silicon-oxygen bonds, Its number average molecular weight is 10000-25000;

[0142] Described dispersion agent selects sodium tripolyphosphate for use;

[0143] The leveling agent is selected from fluorocarbon leveling agent;

[0144] Described siloxane coupling agent selects epoxy coupling agent for use;

[0145] The water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com