Preparation method of biodegradable coating material

A coating material and film-forming liquid technology, applied in the direction of fertilizer mixture, application, fertilization equipment, etc., can solve the problem of high price of coated slow-release fertilizers, and achieve the effects of excellent degradation performance, wide sources, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

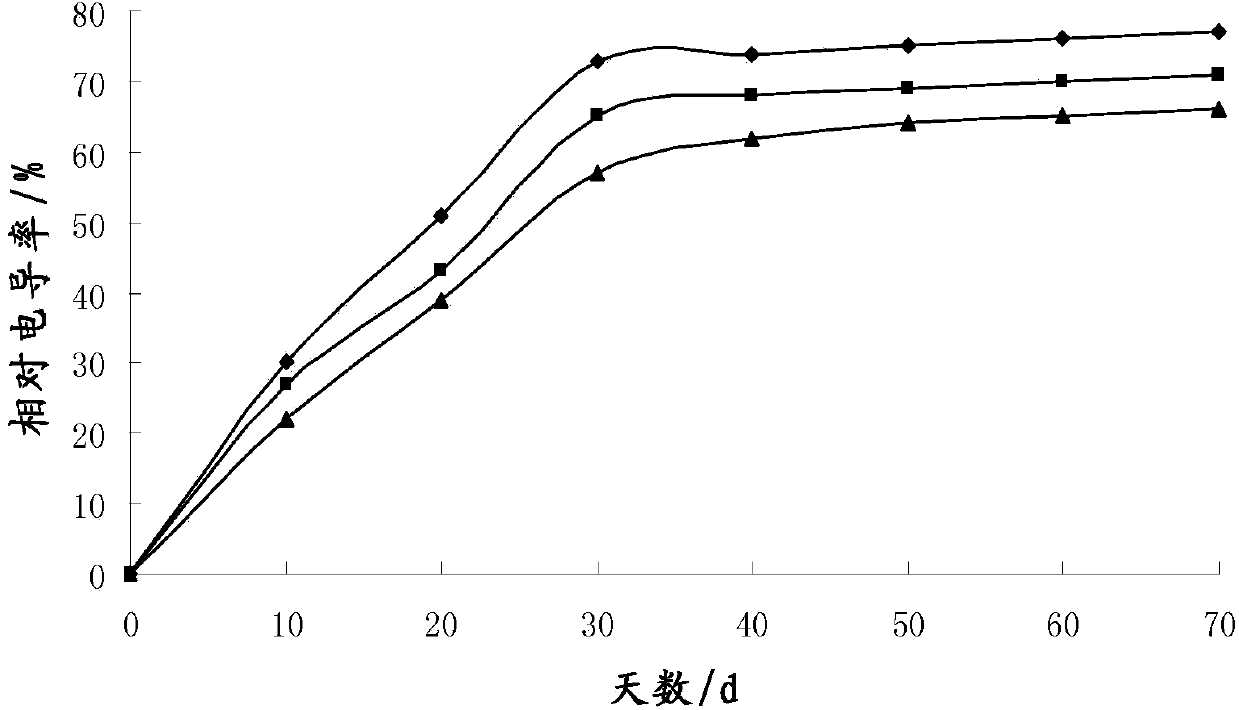

Image

Examples

specific Embodiment approach 1

[0015] Specific Embodiment 1: The preparation method of the degradable coating material in this embodiment is as follows: 1. Mix cornstarch and reinforcing agent, then add 125mL of distilled water, add waterproofing agent and plasticizer, and then put it in a water bath at 90°C to 95°C Stir for 30 minutes to mix evenly, add ammonia water and ethyl silicate dropwise, and mix and stir for 25-30 minutes to obtain a film-forming liquid;

[0016] The consumption of said plasticizer is 73%~75% of the quality of cornstarch, the consumption of waterproofing agent is 18%~20% of the quality of cornstarch, the consumption of ammonia water and ethyl silicate is respectively 0.1%~20% of the quality of cornstarch. 0.3%.

[0017] 2. Cast the film-forming solution on a polytetrafluoroethylene glass plate at room temperature, dry it at 35-40°C, peel off the film, and store the film in a desiccator to obtain a degradable coating material.

[0018] The cornstarch used in step one of the present...

specific Embodiment approach 2

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the reinforcing agent described in step 1 is composed of polyvinyl alcohol and sodium carboxymethyl cellulose in a mass ratio of 9:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the preparation method of the waterproofing agent described in step one is as follows: 50mL water is heated to boiling, and potassium hydroxide 2.25g is added, and the temperature of the solution is Drop to 70°C, add 2g of stearic acid, add 2.25g of triethanolamine when the temperature of the solution drops to 50°C, stir evenly, let stand for 1h, when the temperature of the solution drops to 30°C, add 0.5g of citric acid, let stand for 3h, wait The temperature of the solution is lowered to room temperature, and the pH value is adjusted to be neutral with potassium hydroxide solution to obtain a waterproofing agent. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com