Preparation method of SLATON catalyst for catalyzing visual light to decompose water to prepare oxygen

A catalyst and water splitting technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve the problem of few transition metal nitrogen oxide photocatalysts, and achieve easy operation control, high purity, The effect of simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

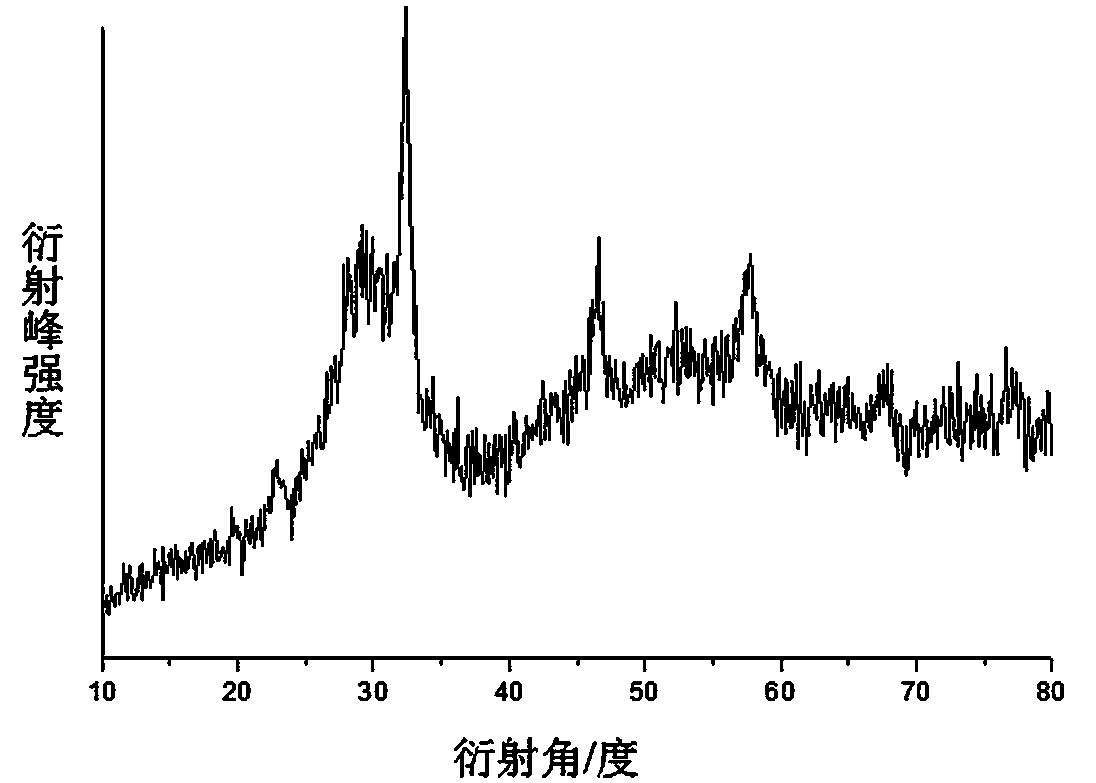

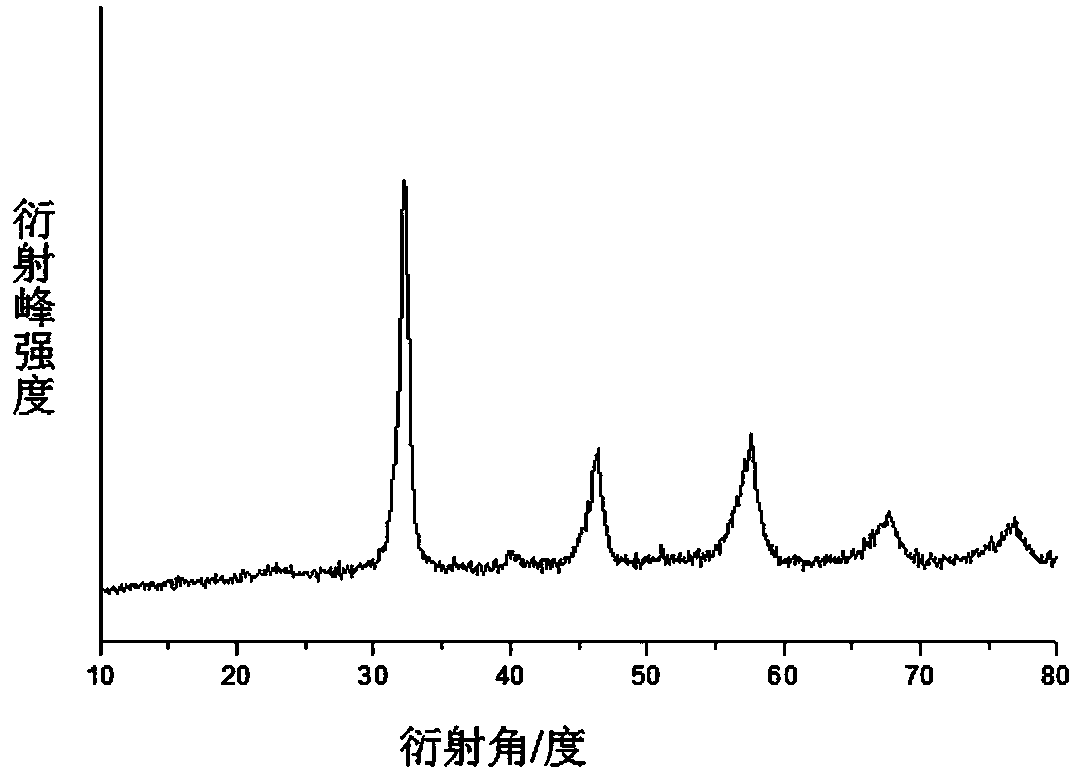

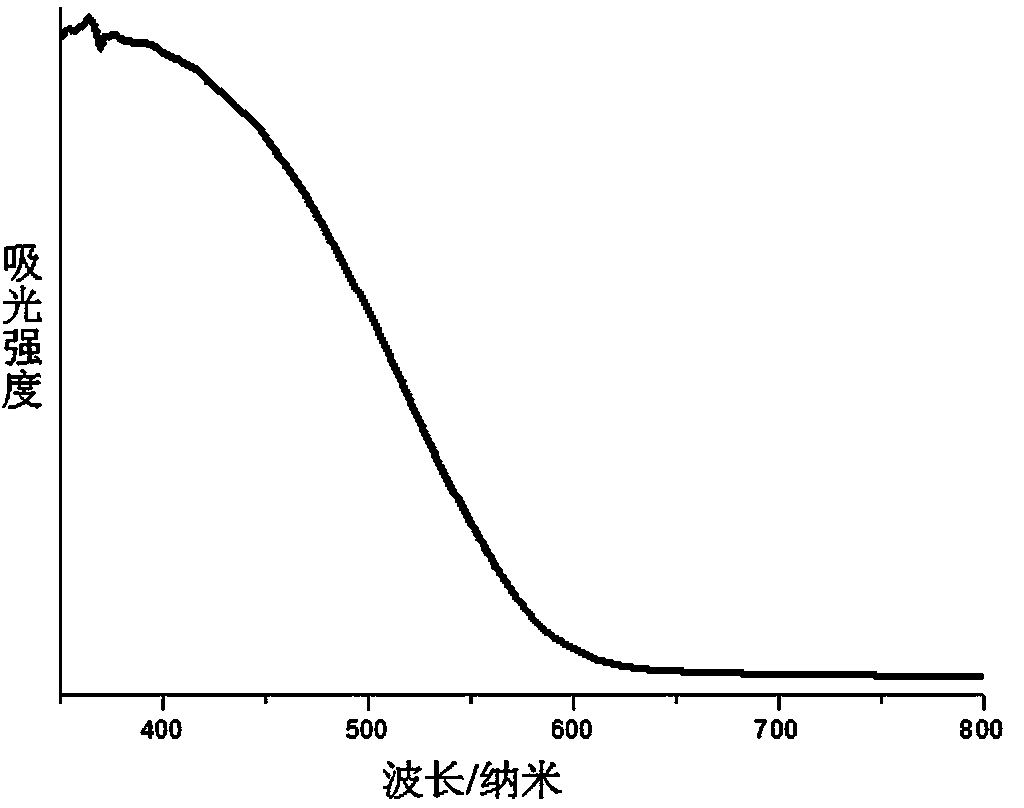

Embodiment 1

[0037] Put strontium chloride, lanthanum chloride, aluminum chloride, tantalum pentachloride and urea in a molar ratio of 1:1:1:1:500, accurately weigh them and put them into methanol aqueous solution (volume ratio of alcohol to water is 1:1) Stir and dissolve in medium for more than 30 minutes. Put the above mixture into a large crucible and put it directly into a muffle furnace. The heating rate of the programmed temperature rise is 10 ℃ / min, the high temperature setting temperature is 800 ℃, and the holding time of the high temperature stage is 4 h. After natural cooling, the obtained Precursor. The precursor is nitrided in an ammonia atmosphere, the nitriding temperature is 850°C, and the time is 6 hours. After cooling, the SLATON powder is obtained. The purity of its products is not less than 99.71%, and the impurity content: carbon is less than 0.11%; chlorine is less than 0.09%. With SLATON as the main catalyst, the co-catalyst CoO is first loaded x , the loadi...

Embodiment 2

[0039] Put strontium nitrate, lanthanum nitrate, aluminum nitrate, tantalum pentachloride and citric acid in a molar ratio of 1:1:1:1:100, accurately weigh them and put them into methanol aqueous solution (alcohol-water volume ratio 1:1) and stir Dissolved for more than 30 minutes. Put the above mixture into a large crucible and put it directly into a muffle furnace. The heating rate of the programmed temperature rise is 10 ℃ / min, the high temperature setting temperature is 800 ℃, and the holding time of the high temperature stage is 4 h. After natural cooling, the obtained Precursor. The precursor is nitrided in an ammonia atmosphere, the nitriding temperature is 850°C, and the time is 6 hours. After cooling, the SLATON powder is obtained. The purity of its products is not less than 99.82%, and the impurity content: carbon is less than 0.13%; chlorine is less than 0.03%. With SLATON as the main catalyst, the co-catalyst CoO is first loaded x , the loading amount is 1...

Embodiment 3

[0041] Put strontium nitrate, lanthanum nitrate, aluminum nitrate, tantalum pentachloride and citric acid in a molar ratio of 1:1:1:1:50, accurately weigh them and put them into methanol aqueous solution (alcohol-water volume ratio 1:1) and stir Dissolved for more than 30 minutes. Put the above mixture into a large crucible and put it directly into a muffle furnace. The heating rate of the programmed temperature rise is 10 ℃ / min, the high temperature setting temperature is 800 ℃, and the holding time of the high temperature stage is 4 h. After natural cooling, the obtained Precursor. The precursor is nitrided in an ammonia atmosphere, the nitriding temperature is 850°C, and the time is 6 hours. After cooling, the SLATON powder is obtained. The purity of its products is not less than 99.86%, and the impurity content: carbon is less than 0.06%; chlorine is less than 0.01%. With SLATON as the main catalyst, the co-catalyst IrO is first loaded 2 , the loading amount is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com