Egg-milk powder essence composition and preparation method thereof

A technology of powder essence and composition, which is applied in the field of food flavor, can solve problems such as unsatisfactory fluidity and solubility, custard powder essence flavor stimulation, and poor thermal stability, etc., to overcome flavor stimulation, excellent high temperature stability, flow good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

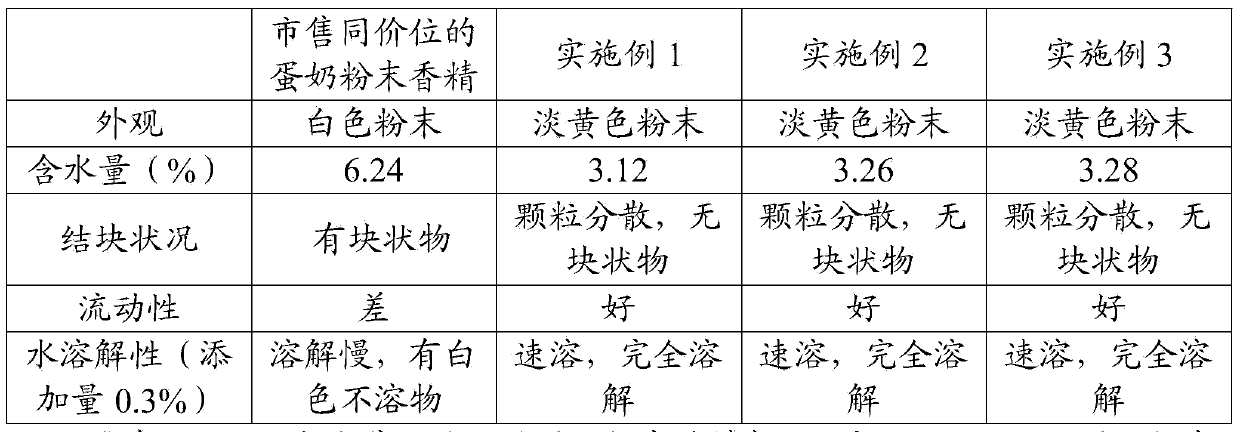

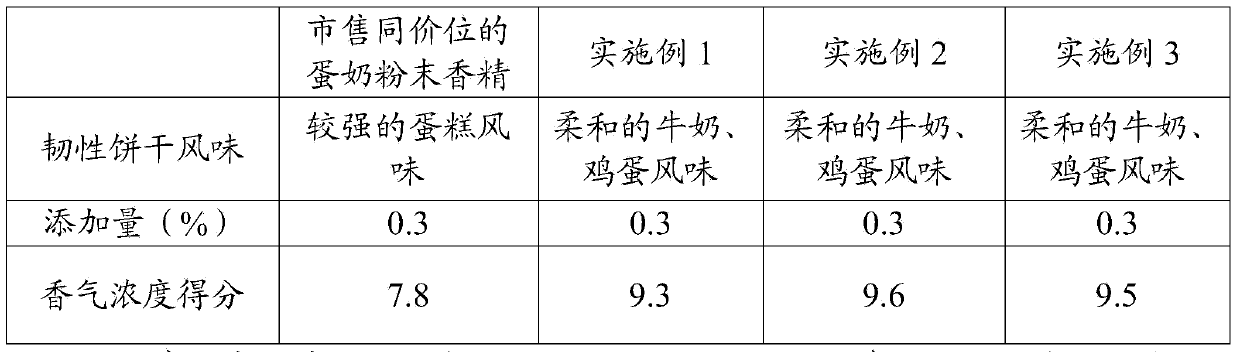

Examples

Embodiment 1

[0029] In this embodiment, a custard powder essence composition comprises the following components in parts by weight:

[0030] 38.0 parts of enzymatic hydrolysis solution, 44.0 parts of maltodextrin, 6.0 parts of sodium starch octenyl succinate, 1.0 parts of glucose powder, 0.2 parts of sodium alginate, 0.3 parts of sodium carboxymethylcellulose, 6.0 parts of custard base, palm 3.5 parts of oil;

[0031] Wherein, the enzymolysis solution is prepared by the following steps:

[0032] Mix buffalo milk and chicken whole egg liquid with a mass ratio of 1:1, add 200U / g protease and 300U / g phospholipase, heat the resulting mixture at 45-55°C, and detect the presence of Ammonia nitrogen, when the mass concentration of ammonia nitrogen is 1.5g / 100g dry basis, the enzymatic hydrolysis solution is obtained.

[0033] The preparation method of above-mentioned custard powder essence composition, comprises the steps:

[0034] (1) take the enzymolysis solution in the clean stainless steel...

Embodiment 2

[0040] In this embodiment, a custard powder essence composition comprises the following components in parts by weight:

[0041] 50.0 parts of enzymatic hydrolysis solution, 37.0 parts of maltodextrin, 4.0 parts of sodium starch octenyl succinate, 3.0 parts of glucose powder, 0.4 parts of sodium alginate, 0.1 parts of sodium carboxymethyl cellulose, 4.0 parts of custard base, palm 1.5 parts oil;

[0042] Wherein, the enzymolysis solution is prepared by the following steps:

[0043] Mix buffalo milk and duck whole egg liquid with a mass ratio of 1:2, add 210U / g protease and 310U / g phospholipase, heat the resulting mixture at 45-55°C, and detect ammoniacal nitrogen, when the mass concentration of ammoniacal nitrogen is 1.4g / 100g dry basis, the enzymatic hydrolysis solution is obtained.

[0044] The preparation method of above-mentioned custard powder essence composition, comprises the steps:

[0045] (1) take the enzymolysis solution in the clean stainless steel tank 1 by the ...

Embodiment 3

[0051] In this embodiment, a custard powder essence composition comprises the following components in parts by weight:

[0052] 44.0 parts of enzymatic hydrolysis solution, 41.0 parts of maltodextrin, 5.0 parts of sodium starch octenyl succinate, 1.5 parts of glucose powder, 0.3 parts of sodium alginate, 0.2 parts of sodium carboxymethylcellulose, 5.0 parts of custard base, palm 2.5 parts of oil;

[0053] Wherein, the enzymolysis solution is prepared by the following steps:

[0054] Mix buffalo milk and goose whole egg liquid with a mass ratio of 1:1, add 190U / g protease and 290U / g phospholipase, heat the resulting mixture at 45-55°C for reaction, and detect the presence in the reaction solution at this temperature ammoniacal nitrogen, when the mass concentration of ammoniacal nitrogen is 1.2g / 100g dry basis, the enzymatic hydrolysis solution is obtained.

[0055] The preparation method of above-mentioned custard powder essence composition, comprises the steps:

[0056] (1) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com