Method for preparing controlled degradation metal composite coating on surface of medical magnesium alloy

A metal composite and magnesium alloy technology, applied in metal material coating process, device for coating liquid on the surface, coating, etc., can solve problems such as controllable degradation of magnesium alloy, singleness, and decline in material biological activity. Achieve good biological activity and cell affinity, tight binding, precise and controllable degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

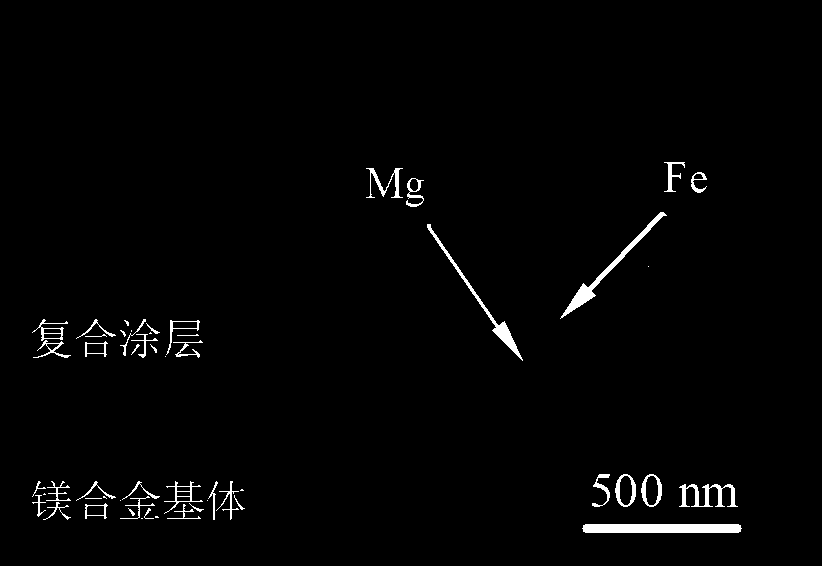

[0025] Example 1: Prepare Mg / Fe controllable degradable metal composite coating on the surface of pure magnesium (Mg99.95) according to the following steps

[0026] Step 1: Degrease, sandpaper and mechanically polish the surface of pure magnesium, wash it with acetone and absolute ethanol, and dry it for use;

[0027] Step 2: Carry out the film growth of the Mg / Fe metal composite coating on the physical vapor deposition equipment; the thickness of the Mg / Fe metal composite coating is 100 nm, the number of cycles is 20, and the modulation ratio is 1:10; The side of the Mg / Fe metal composite coating close to the substrate is a Mg layer, and then an Fe layer.

Embodiment 2

[0028] Example 2: Prepare Mg / Fe controllable degradation metal composite coating on the surface of Mg-Al-Zn alloy (AZ31 magnesium alloy) according to the following steps

[0029] Step 1: Degrease, sandpaper and mechanically polish the surface of the AZ31 magnesium alloy, wash it with acetone and absolute ethanol, and dry it for use;

[0030] Second step: utilize the chemical vapor deposition method to carry out the coating growth of Mg / Fe metal composite coating on magnesium alloy; The thickness of described Mg / Fe metal composite coating is 1000 nm, and cycle number is 10, and modulation ratio is 1: 2; The side of the Mg / Fe metal composite coating close to the substrate is a Mg layer, and then an Fe layer.

Embodiment 3

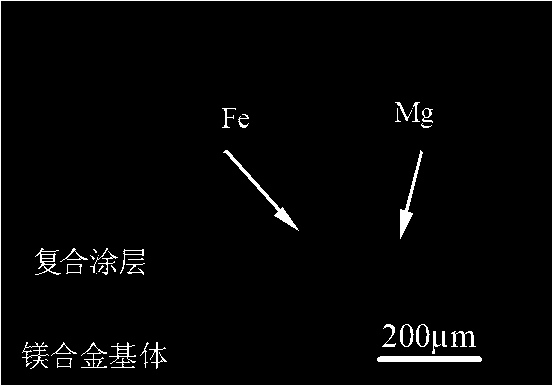

[0031] Example 3: Prepare Mg / Fe controllable degradation metal composite coating on the surface of Mg-Al-Zn alloy (AZ61 magnesium alloy) according to the following steps

[0032] Step 1: Degrease, sandpaper and mechanically polish the surface of the AZ61 magnesium alloy, wash it with acetone and absolute ethanol, and dry it for use;

[0033] Second step: carry out the preparation of Mg / Fe metal composite coating on cold spray equipment; The thickness of described Mg / Fe metal composite coating is 1000 μ m, and cycle number is 2, and modulation ratio is 10:1 (1: 0.1); the Mg / Fe metal composite coating is a Mg layer on one side of the substrate, and then an Fe layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com