A kind of anti-ultraviolet radiation transparent high barrier film and its application

A high-barrier film, anti-ultraviolet technology, used in gaseous chemical plating, coating, layered products, etc., can solve problems affecting the appearance of packaging, and achieve the effect of preventing surface adsorption, thin coating, and high barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0043] In embodiment 3, a=4, b1=11,

[0044] but

[0045] The nitrogen-doped titanium dioxide layer of the present invention can be formed in a known manner, preferably by vacuum coating equipment, such as chemical vapor deposition, sputtering, etc., more preferably by plasma chemical vapor deposition. The nitrogen-doped titanium dioxide layer of the present invention can be formed by plating one or more times. The total thickness of the nitrogen-doped titanium dioxide layer is 100-300 nm, preferably 150-200 nm. If the nitrogen-doped titanium dioxide layer is too thick, the coating is easy to become brittle , Membrane rupture occurs during use, which affects performance, and at the same time, causes high cost and is uneconomical; if the coating is too thin, the anti-ultraviolet effect is not good.

[0046] Nitrogen-doped titanium dioxide can red-shift the ultraviolet absorption peak, and can have strong absorption for ultraviolet rays below 400nm. At the same time, the nitro...

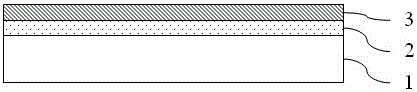

Embodiment 1

[0076] A 100nm-thick silicon oxide layer (2) was plated on a PET substrate (1) with a thickness of 12 μm and a light transmittance of 91% by plasma-enhanced chemical vapor deposition; the process parameters were:

[0077] Pulse power 30w Oxygen to Monomer Ratio o 2 :HMDSO 2:1 duty cycle 15% work pressure 10Pa

[0078] A 200nm-thick nitrogen-doped titanium oxide layer (3) with a nitrogen content of 1% is plated on the silicon oxide layer (2) by plasma-enhanced chemical vapor deposition (PECVD), and the process parameters are:

[0079] RF Power 30w Monomer to Nitrous Oxide Flow Ratio Ti (IPO 4 ) :N 2 o 8:1 Oxygen to monomer flow ratio o 2 :Ti(IPO 4 ) 4:1 work pressure 65Pa

[0080] The specific structure is as figure 1 shown.

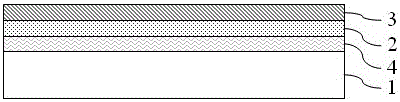

Embodiment 2

[0082] The process parameters for plating a 120nm thick titanium oxide layer (4) on a PEN substrate (1) with a thickness of 12 μm and a light transmittance of 87% by plasma enhanced chemical vapor deposition are:

[0083] RF Power 20w Oxygen to monomer flow ratio o 2 :Ti(IPO 4 ) 3:1 work pressure 65Pa

[0084] A 100nm-thick aluminum oxide layer (2) is plated on the titanium oxide layer (4) by ion evaporation or sputtering, and a 150nm-thick nitrogen-doped nitrogen content of 1% is plated on the aluminum oxide layer (2). Titanium heterooxide layer (3), the process parameters are the same as those in Example 1. The specific structure is as figure 2 shown.

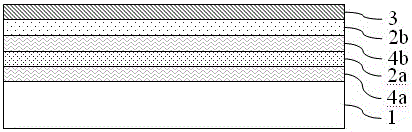

[0085] Example 3

[0086] A 50nm-thick first titanium oxide layer (4a) was plated on a PET substrate (1) with a thickness of 100 μm and a light transmittance of 89% by plasma-enhanced chemical vapor deposition (PECVD); on the first titanium oxide layer (4a ) layer is coated with silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com