Method for preparing magnetic nanosheet

A magnetic nanometer and magnetic material technology, applied in nanotechnology, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problem of low yield of nanoparticles, and achieve the effect of easy removal or recycling, low cost and wide variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

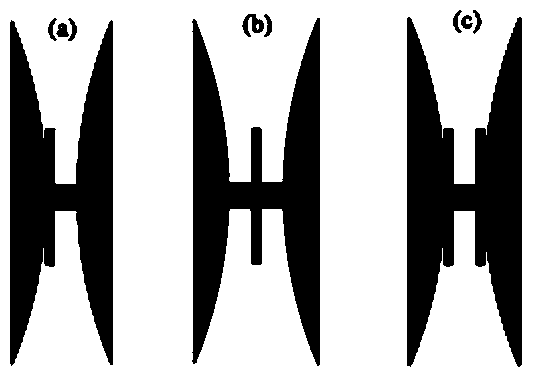

Method used

Image

Examples

Embodiment 1

[0069] 1. Weigh the coarsely crushed PrCo 5 Put 5g of material (particle size less than 100μm) into a stainless steel ball mill jar, then add 100g of stainless steel balls (20g of 8mm, 80g of 5mm), then add 15g of NaCl solid particles (particle size of 100μm) and 1ml of oleic acid And 1ml of oleylamine as surfactant, finally add 100ml of n-heptane organic solvent.

[0070] 2. Seal the ball mill tank containing raw materials, grinding balls, surfactants, solid particles, and organic solvents in a glove box.

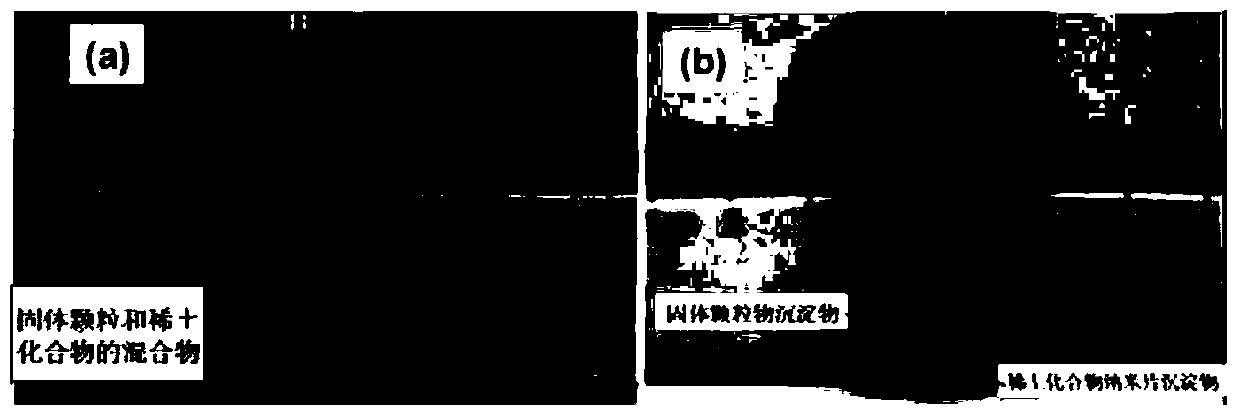

[0071] 3. Put the sealed ball mill jar on a GN-2 high-energy ball mill, and mill it at a voltage of 50v (about 300 rpm) for 20 hours. Take out the balls, pour the milled product into a centrifuge tube, shake and stir for 10 minutes, then let stand for 10 hours, as figure 2 (b) shown.

[0072] 4. Use a straw to remove the upper liquid and solid particle layer, leaving only the bottom layer of black PrCo 5 The nanosheet precipitate was washed five times with n-heptane, ...

Embodiment 2

[0096] 1. Weigh the coarsely crushed powdered PrCo 5 5g of material (its particle size is less than 100μm), put it into a stainless steel ball mill jar, then add 100g of stainless steel grinding balls (20g for 8mm, 80g for 5mm), and then add 15g of Al 2 o 3 Solid particles (particle size 100 μm) and 4ml of oleic acid are used as surfactants, and finally 100ml of n-heptane organic solvent is added.

[0097] 2. Seal the ball mill tank containing raw materials, grinding balls, surfactants, solid particles, and organic solvents in a glove box.

[0098] 3. Put the sealed ball mill jar on a GN-2 high-energy ball mill, and mill it for 10 hours at a voltage of 55v (about 350 rpm). Take out the balls, pour the milled product into a centrifuge tube, shake and stir for 10 minutes, and then let stand for 10 hours. It is also seen that solid particles and PrCo after ball milling 5 Clear separation of rare earth compounds.

[0099] 4. Use a pipette to remove the upper layer and the sol...

Embodiment 3

[0102] 1. Weigh the coarsely crushed powdered PrCo 5 Material 5g (particle size is less than 100μm), put into stainless steel ball mill tank, then add 100g of stainless steel balls (20g of 8mm, 80g of 5mm) and 1ml of oleic acid and 1ml of oleylamine surfactant; finally add 100ml of normal heptane.

[0103] 2. Seal the ball mill tank containing raw materials, grinding balls, surfactants and organic solvents in a glove box.

[0104] 3. Put the sealed ball mill jar on the GN-2 high-energy ball mill, and ball mill for 5 hours at a voltage of 50v (about 300 rpm). Then take out the ball mill jar, open the ball mill jar in the glove box, and add 15 g of NaCl solid particles (particle size 100 μm), and then seal it. The packaged ball mill jars were placed on a GN-2 high-energy ball mill to continue ball milling for 15 hours. Take out the balls, pour the milled product into a centrifuge tube, shake and stir for 10 minutes, and then let stand for 10 hours. A clear separation of soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com