Manufacture method for flexible large-area high-heat-power electrothermal film

A production method and large-area technology, applied in the direction of electric heating devices, electrical components, heating by discharge, etc., can solve the problems of large initial investment, limited heating power, troubles, etc., and achieve large contact area, fast heat generation and heat dissipation, and heat transfer effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

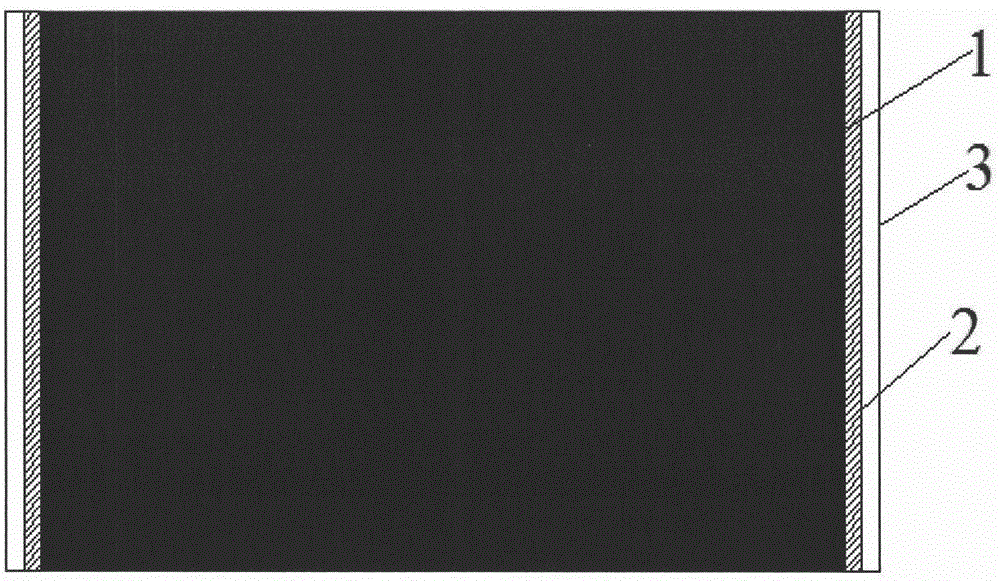

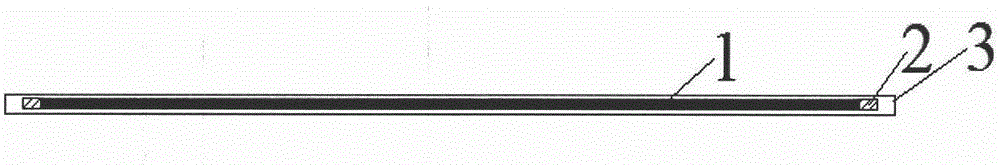

[0016] Such as figure 1 and figure 2 As shown, the flexible large-area high-heating power electric heating film of the present invention is a rectangle, and it comprises an electric heating film 1, a copper electrode 2 and a sealing insulator 3; firstly, the conductive film is prepared, and 10g of carbon black particles are added to 100g of naphtha In the solvent, after ultrasonic dispersion is uniform, add 100g of silicone rubber and stir evenly, then add 4g of curing agent; inject the mixed solution into the mold at room temperature for 48 hours to cure and form an electric heating film; finally, conductively bond the conductive film to the copper electrode and use insulating polymer Ester film sealing treatment, the electric heating film is first pasted on a polyester film, and then another polyester film is pasted on the upper surface. After the adhesive is cured, a complete flexible large-area high-heating power electric heating is obtained. film. When using, just conn...

Embodiment 2

[0018] Such as figure 1 and figure 2 As shown, the flexible large-area high-heating power electric heating film of the present invention is a rectangle, and it includes an electric heating film 1, a copper electrode 2 and a sealing insulator 3; firstly, the conductive film is prepared, and 15g of carbon black particles are added to 150g of naphtha In the solvent, after ultrasonic dispersion is uniform, add 100g of silicone rubber and stir evenly, then add 4g of curing agent; inject the mixed solution into the mold at room temperature for 48 hours to cure and form an electric heating film; finally, conductively bond the conductive film to the copper electrode and use insulating polymer Ester film sealing treatment, first paste the electric heating film on a polyester film, and then paste another polyester film on the upper surface. After the adhesive is cured, a complete flexible large-area high-heating power electric heating is obtained. film. When using, just connect the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com