Front structure of power semiconductor chip and manufacturing method of front structure of power semiconductor chip

A power semiconductor, front-side structure technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of increased chip process costs, high-temperature processing processes, and complicated power semiconductor chip manufacturing process flow, so as to reduce manufacturing costs and reduce Process cost and the effect of reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

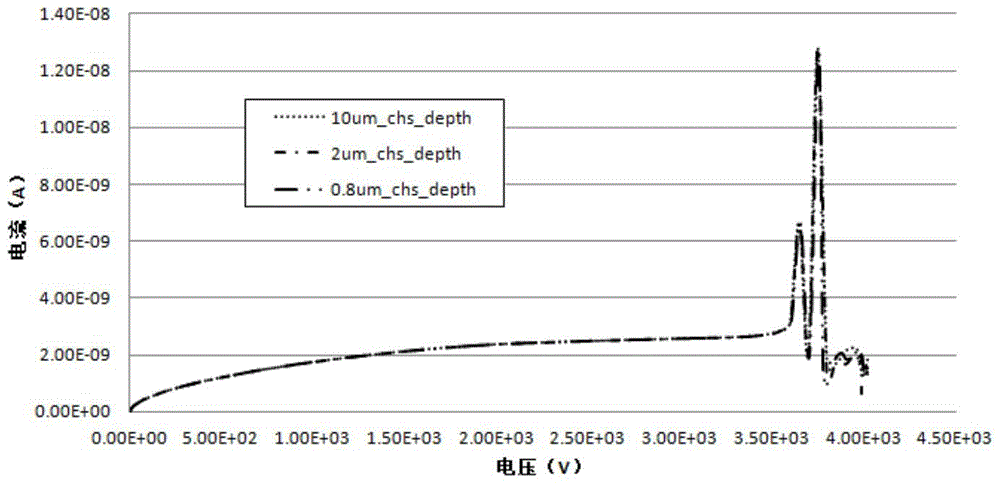

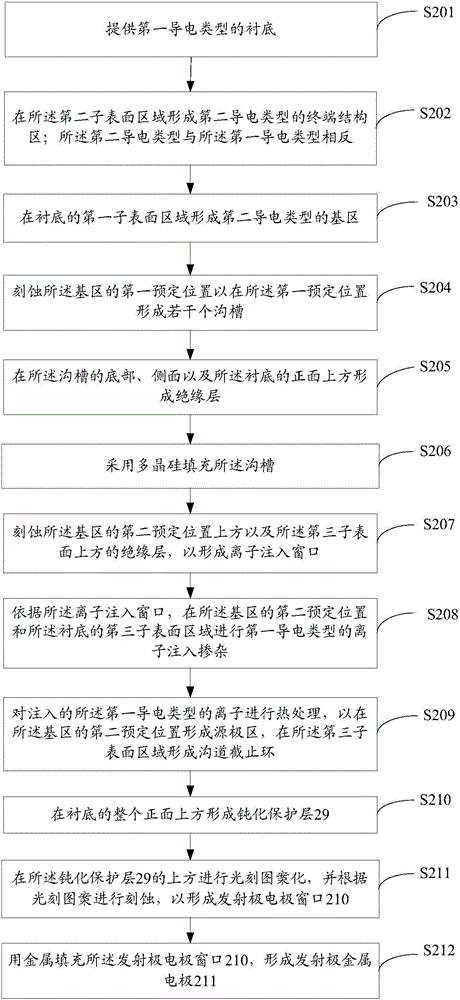

[0050]Based on the research findings of the inventors, it can be seen that when the terminal structure region and the channel stop ring are separated by a preset distance, the junction depth of the channel stop ring has no direct relationship with the withstand voltage capability of the chip itself. Therefore, the channel stop ring can be Junction depth is reduced. And because the doping type of the channel stop ring is the same as that of the electrode source region, the formation process of the electrode source region and the formation process of the channel stop ring can be combined to prepare the electrode source region at the same time and the channel stop ring, thereby saving one-step photolithography process and one-step doping process, thereby achieving the purpose of optimizing the front-side process flow of the power semiconductor ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com