Preparation method of supercapacitor carbon material

A technology of supercapacitors and carbon materials, applied in the manufacture of hybrid/electric double layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of excessive use of organic chemical reagents, small specific volume of electrode materials, and no practical application value, etc., to achieve easy large-scale Batch preparation and industrial production, the effect of increasing specific volume and large specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

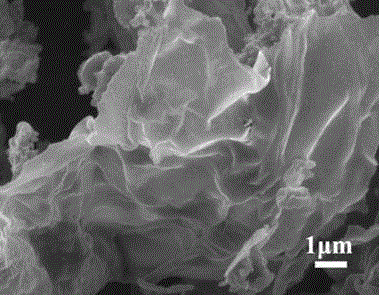

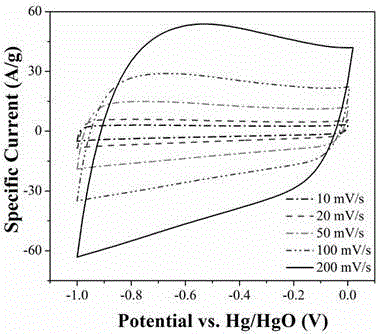

Image

Examples

Embodiment 1

[0026] A kind of preparation method of carbon material for supercapacitor is characterized in that, comprises following operation:

[0027] ①Water heat: Make the volume 3cm 3 The radish pieces are completely immersed in a reaction kettle filled with 30ml of 10% thiourea solution in mass percent concentration, the reaction kettle is sealed and placed in an oven at 200°C for 6 hours, then cooled to room temperature, and the block water is taken out. gel;

[0028] ②Removal of impurities: Soak the massive hydrogel obtained in ① in absolute ethanol and pure water for 3 times, each time for 8 hours, to remove impurities;

[0029] ③Freeze-drying: pre-freeze the block hydrogel obtained in ② at -50°C for 6 hours, then freeze-dry at -60°C and 1Pa pressure for 48 hours to obtain block airgel;

[0030] ④Calcination: Calcinate the bulk airgel obtained in ③at 850°C for 1.5 hours in an argon atmosphere, and grind the airgel into gel powder after cooling;

[0031] ⑤Activation: Mix the gel ...

Embodiment 2

[0034] A kind of preparation method of carbon material for supercapacitor is characterized in that, comprises following operation:

[0035] ①Water heat: Make the volume 4cm 3 The chunky pomelo peels are completely immersed in a reaction kettle filled with 60ml of 5% thiourea solution by mass percentage, the reaction kettle is sealed and placed in an oven at 220°C for 4 hours, then cooled to room temperature, and the block is taken out. shaped hydrogel;

[0036] ②Removal of impurities: Soak the massive hydrogel obtained in ① in absolute ethanol and pure water for 3 times, each time for 8 hours, to remove impurities;

[0037] ③Freeze-drying: pre-freeze the block hydrogel obtained in ② at -50°C for 6 hours, then freeze-dry at -60°C and 1Pa pressure for 48 hours to obtain block airgel;

[0038] ④Calcination: calcining the massive airgel obtained in ③at 800°C for 2 hours in an argon atmosphere, and grinding the airgel into gel powder after cooling;

[0039] ⑤Activation: Mix the ...

Embodiment 3

[0042] A kind of preparation method of carbon material for supercapacitor is characterized in that, comprises following operation:

[0043] ①Water heat: Make the volume 6cm 3 The sweet potato pieces are completely immersed in a reaction kettle filled with 30ml of 15% thiourea solution by mass percentage, the reaction kettle is sealed and placed in an oven at 190°C for 8 hours, then cooled to room temperature, and the block water is taken out. gel;

[0044] ②Removal of impurities: Soak the massive hydrogel obtained in ① in absolute ethanol and pure water for 3 times, each time for 8 hours, to remove impurities;

[0045]③Freeze-drying: pre-freeze the block hydrogel obtained in ② at -50°C for 6 hours, then freeze-dry at -60°C and 1Pa pressure for 48 hours to obtain block airgel;

[0046] ④Calcination: calcining the bulk airgel obtained in ③at 900°C for 1 hour in an argon atmosphere, and grinding the airgel into gel powder after cooling;

[0047] ⑤Activation: Mix the gel powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com