Addition-type bi-component heat-conducting pouring sealant and preparation method thereof

A thermally conductive potting, two-component technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor substrate adhesion, no adhesion, and poor adhesion. , to achieve the effect of improving adhesive properties, excellent adhesive properties and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

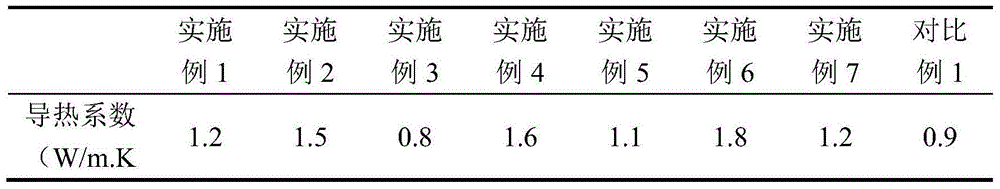

[0027] The addition-type two-component heat-conducting potting compound in this embodiment is composed of two components, A and B, in parts by weight.

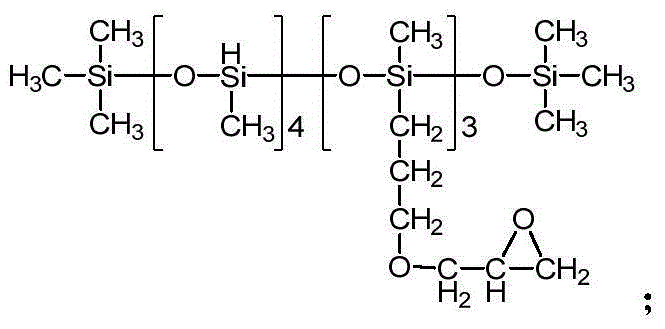

[0028] Component A: 100 parts of vinyl silicone oil with a viscosity of 300cp, 2 parts of hydrogen-containing silicone oil with a hydrogen content of 0.25%, 200 parts of filler aluminum oxide, 100 parts of silicon carbide and 100 parts of magnesium oxide, 1-ethynyl-1 0.2 parts of cyclohexanol, 5 parts of tackifier with hydrogen content of 0.35%, the structural formula is:

[0029] Component B: 30 parts of methyl silicone oil with a viscosity of 50 cp, platinum-divinyltetramethyldisiloxane complex with a Pt content of 3000 ppm (purchased from Heraeus, Germany, CAS: 68478-92-2) 0.6 share.

[0030] The preparation method of described tackifier is: get 24g of D 4 H Put 32.6g of vinyltrimethoxysilane in a 250ml three-necked flask, add 30mL of toluene as a solvent, and react under nitrogen protection, the reaction temperature i...

Embodiment 2

[0033] The addition-type two-component heat-conducting potting compound in this embodiment is composed of two components, A and B, in parts by weight.

[0034] Component A: 100 parts of vinyl silicone oil with a viscosity of 500cp, 2 parts of hydrogen-containing silicone oil with a hydrogen content of 0.3%, 150 parts of filler aluminum oxide, 100 parts of aluminum nitride, 250 parts of magnesium oxide, tetramethyltetraethylene 0.25 parts of cyclotetrasiloxane, 5 parts of tackifier with hydrogen content of 0.4%, the structural formula is:

[0035] Component B: 30 parts of methyl silicone oil with a viscosity of 50 cp, 0.6 parts of chloroplatinic acid-isopropanol solution with a Pt content of 3%.

[0036] The preparation method of described tackifier is: get 24g of D 4 H Place 27.4g of allyl glycidyl ether in a 250ml three-necked flask, add 30mL of toluene as a solvent, and react under nitrogen protection. The reaction temperature is 70°C, and the reaction time is 4 hours; a...

Embodiment 3

[0039] The addition-type two-component heat-conducting potting compound in this embodiment is composed of two components, A and B, in parts by weight.

[0040] Component A: 100 parts of vinyl silicone oil with a viscosity of 1000cp, 1 part of hydrogen-containing silicone oil with a hydrogen content of 0.4%, 200 parts of filler aluminum oxide and 100 parts of silicon carbide, tetramethyltetravinyl cyclotetrasiloxane 0.15 parts, 4 parts of tackifier with hydrogen content of 0.4%, the structural formula is:

[0041] Component B: 30 parts of methyl silicone oil with a viscosity of 50 cp, 0.6 parts of chloroplatinic acid-tetrahydrofuran solution with a Pt content of 3%.

[0042] The preparation method of described tackifier is: get 24g of D 4 HPut 16.3g of vinyltrimethoxysilane and 13.7g of allyl glycidyl ether into a 250ml three-necked flask, add 30mL of toluene as a solvent, and react under nitrogen protection. The reaction temperature is 80°C, and the reaction time is For 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com