Polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polypropylene modified composite materials and its preparation, can solve the problems of easy cracking, slow heat exchange rate, poor impact resistance, etc., achieve good interfacial compatibility, improve interface Combining and improving the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

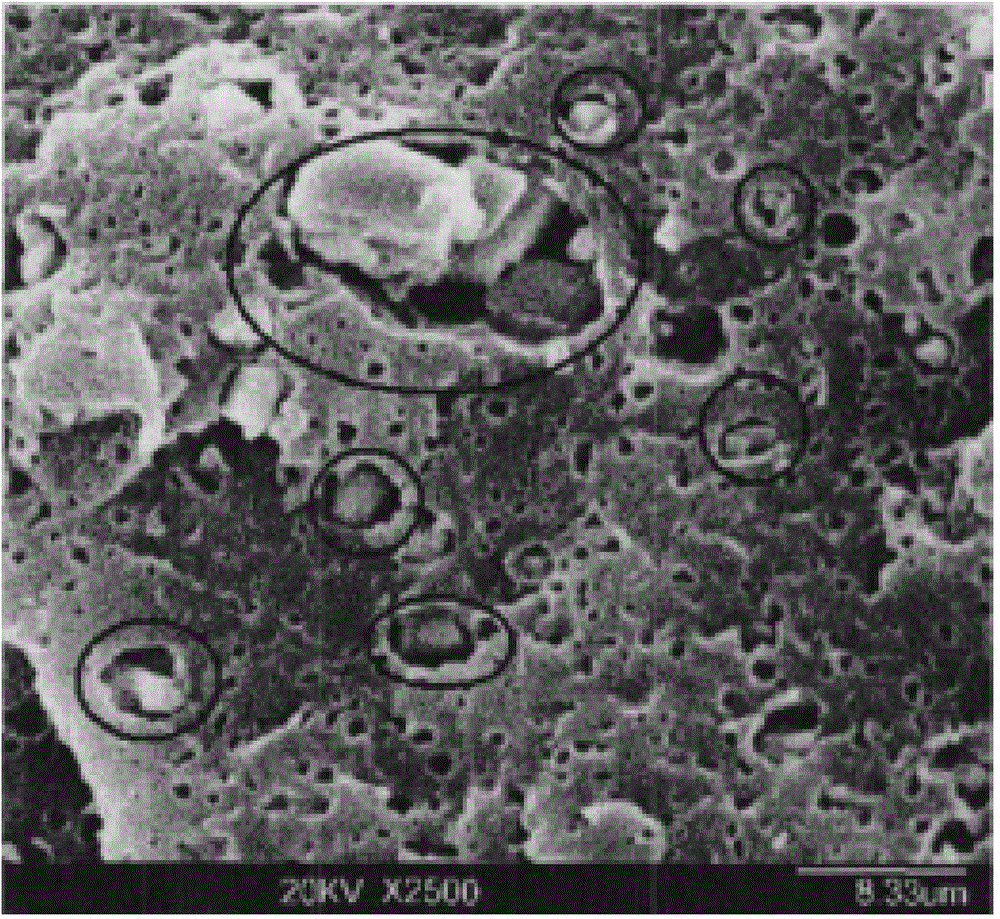

Image

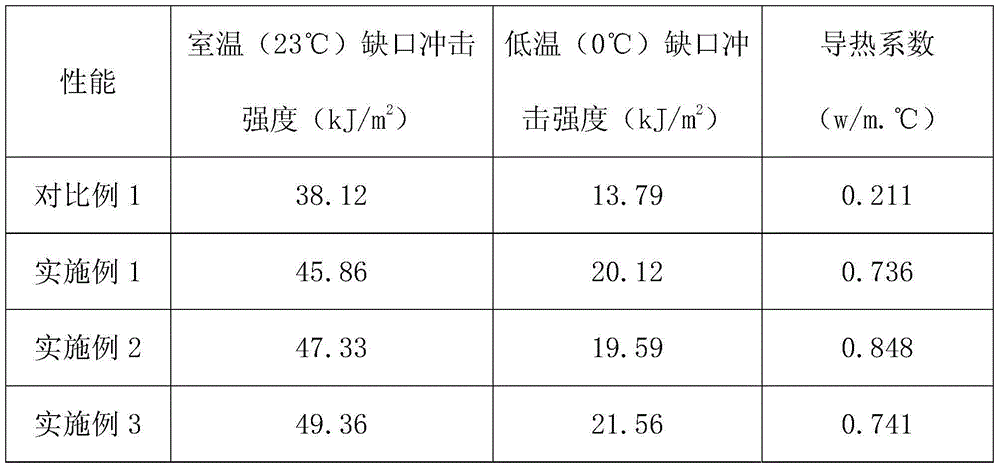

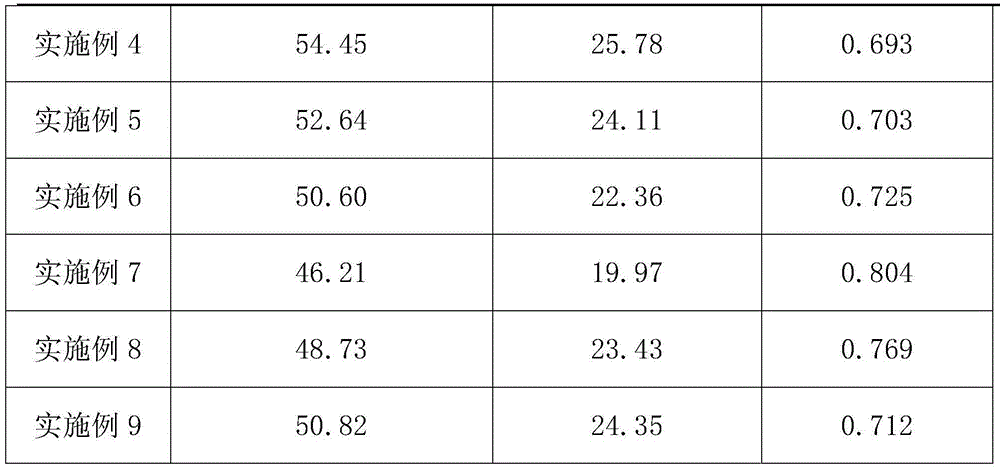

Examples

Embodiment 1

[0015] (1) Pour 100 parts by weight of alumina fillers with a size of 6000 mesh into distilled water at 100 ° C, ultrasonically disperse for 1 hour, take out and dry for later use, 1 weight part of aluminum ester acid coupling agent is dissolved in ethanol solution for alcoholysis For 1 hour, add the nano thermal conductive filler for drying, stir at a constant temperature of 75°C for 1 hour, vacuum filter, dry, grind and sieve to obtain the surface-treated alumina filler;

[0016] (2) 100 parts by weight of modified alumina filler and 20 parts by weight of maleic anhydride grafted polyolefin elastomer, 1.5 parts by weight of antioxidant 1010, 2 parts by weight of stearic acid are directly put into high-speed mixer and carried out Initial mixing, mixing at room temperature;

[0017] (3) moving the mixture obtained in the step (2) into the twin-screw and kneading evenly, the extrusion temperature is 200 ° C, water-cooled granulation, and fully dried;

[0018] (4) mixing the ma...

Embodiment 2

[0020] (1) 120 parts by weight of alumina fillers with a size of 7000 objects are first subjected to surface treatment with an aluminum ester acid coupling agent; the consumption of the aluminum ester acid coupling agent is 1 part by weight;

[0021] (2) 120 parts by weight of modified alumina filler and 25 parts by weight of maleic anhydride grafted polyolefin elastomer, 1.5 parts by weight of antioxidant 1010, 2 parts by weight of stearic acid are directly put into high-speed mixer and carried out Initial mixing, mixing at room temperature;

[0022] (3) moving the mixture obtained in the step (2) into the twin-screw and kneading evenly, the extrusion temperature is 200 ° C, water-cooled granulation, and fully dried;

[0023] (4) The material obtained in the step (3) and 100 parts by weight of polypropylene are mixed in a high-speed mixer, mixed at room temperature, and then subjected to secondary extrusion and granulation, and the extrusion temperature is 220 ° C. After wate...

Embodiment 3

[0025] (1) 100 parts by weight of zinc oxide fillers with a size of 6500 meshes are first subjected to surface treatment with a titanate acid coupling agent; the amount of the titanate coupling agent is 1 part by weight;

[0026] (2) 100 parts by weight of modified zinc oxide filler and 25 parts by weight of maleic anhydride grafted polyolefin elastomer, 1.5 parts by weight of antioxidant 1010, 2.5 parts by weight of stearic acid are directly put into the high-speed mixer and carried out Initial mixing, mixing at room temperature;

[0027] (3) moving the mixture obtained in the step (2) into the twin-screw and kneading evenly, the extrusion temperature is 200 ° C, water-cooled granulation, and fully dried;

[0028] (4) The material obtained in the step (3) and 100 parts by weight of polypropylene are mixed in a high-speed mixer, mixed at room temperature, and then subjected to secondary extrusion and granulation, and the extrusion temperature is 220 ° C. After water cooling A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com