A preparation method of high-strength low-density fracturing proppant

A fracturing proppant and solvent technology, applied in the field of fracturing oil production, can solve the problems of high equipment requirements, high sphericity of proppant, complicated preparation process, etc., and achieve the effects of reducing pollution, reducing construction cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

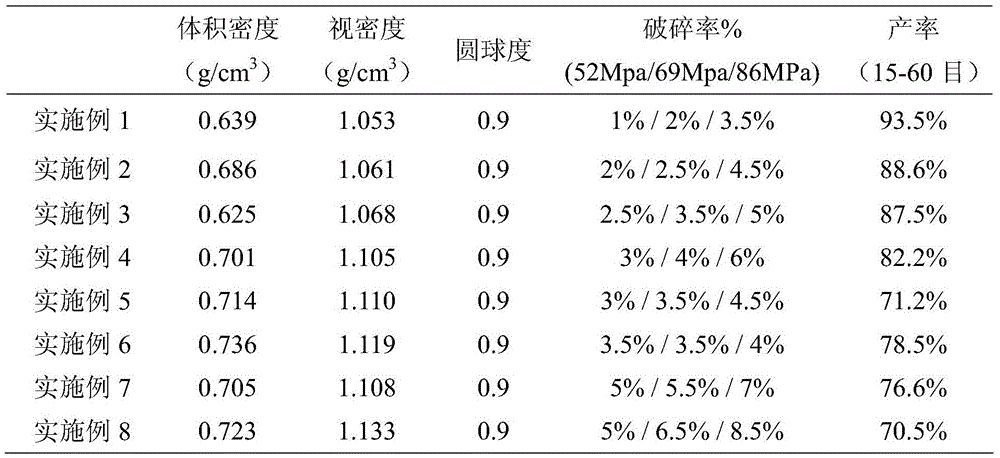

Examples

preparation example Construction

[0021] The preparation process of the fracturing proppant of the present invention is as follows:

[0022] 1) Dispersing the earthy graphite in an ethanol solvent, then adding a surfactant, heating and stirring, cooling, suction filtering, and drying to obtain modified earthy graphite;

[0023] 2) Add the modified earthy graphite to the methyl methacrylate monomer solution in which the crosslinking agent and initiator are dissolved; use water as the dispersant and add polyvinyl alcohol and suspending agent, and synthesize the organic / The inorganic composite microspheres are filtered, washed, dried, and passed through a 15-60 mesh sieve to obtain a fracturing proppant. By adding a certain amount of mineral materials in the polymer synthesis process, the strength and temperature resistance of the polymer can be improved, so it is suitable for deep well fracturing.

[0024] Optimally, the mass ratio of the surfactant to the earthy graphite in step 1) is (0.1-1):10.

[0025] O...

Embodiment 1

[0032] (1) Modification of soil-like graphite: Weigh 20 g of soil-like graphite, add it to ethanol solvent, add 0.2 g of sodium dodecylbenzenesulfonate, heat and stir continuously, cool, suction filter, and dry for later use.

[0033] (2) Preparation of composite microspheres: Heat and stir 0.095g of polyvinyl alcohol in a three-necked flask with water as the dispersion medium, then add 0.10g of sodium hydroxide and 0.305g of magnesium chloride hexahydrate and continue to stir, and take 0.2g of modified soil Add graphite into 20g of methyl methacrylate (MMA) monomer solution in which 5g of divinylbenzene and 0.5g of benzoyl peroxide are dissolved, then add the mixture into a three-necked flask, synthesize composite microspheres by suspension polymerization, and filter , washed with water, dried, and passed through a 15-60 mesh sieve to obtain the desired sample, that is, a high-strength and ultra-low-density fracturing proppant product.

Embodiment 2

[0035] (1) Modification of earthy graphite: Weigh 20 g of earthy graphite, add it to ethanol solvent, add 2 g of sodium lauryl sulfate, heat and stir continuously, cool, suction filter, and dry for later use.

[0036] (2) Preparation of composite microspheres: Heat and stir 0.17g of polyvinyl alcohol in a three-neck flask with water as the dispersion medium, then add 0.8g of sodium hydroxide and 2.03g of magnesium chloride hexahydrate and continue stirring, and take 1g of modified soil Graphite is added in the 20g methyl methacrylate (MMA) monomer solution that is dissolved with 5g cyclopentadiene and 0.2g cumene hydroperoxide, then the mixture is added to the there-necked flask, and composite microspheres are synthesized by suspension polymerization, Filter, wash with water, dry, and pass through a 15-60 mesh sieve to obtain the desired sample, namely a high-strength and ultra-low-density fracturing proppant product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com