Mechanical finger installation full angle protection sleeve device

A technology of mechanical fingers and protective sleeves, which is applied in the field of installing full-angle protective sleeves on mechanical fingers, which can solve problems such as low efficiency of wrapping angles, easy bruises, and hidden dangers to workers’ health, so as to achieve high work efficiency and save labor costs , the effect of protecting the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

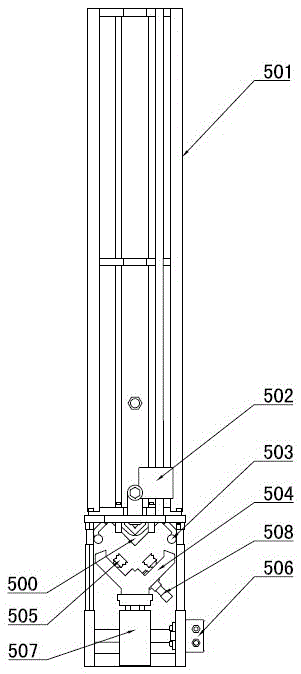

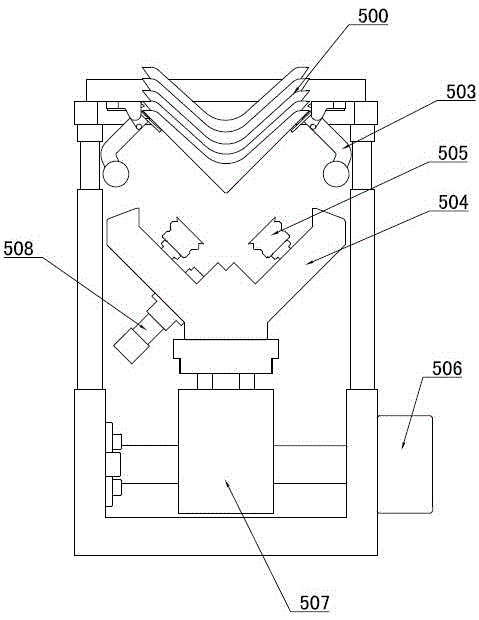

[0027] Figure 1-2 It is the best embodiment of this mechanical finger to install the full angle protective sleeve device, below in conjunction with the attached Figure 1-10 The present invention will be further described.

[0028] Refer to attached Figure 1-2 : The mechanical finger is equipped with a full-covered corner protective cover device, including a full-covered corner storehouse 501, a corner support device 502, a grabbing device, a rotating device 506 and a telescopic device 507, and the full-covered corner storehouse 501 is placed vertically, and multiple full-covered corners are placed vertically. The wrap angle 500 is vertically stacked and stored in the full wrap angle storage warehouse 501. The full wrap angle storage warehouse 501 is a silo slideway composed of two straight rods and two straight rods slotted inside. The full wrap angle 500 can be Slidingly installed in the silo slideway.

[0029] The bottom of the all-inclusive corner 500 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com