Method of Surfacing Formed Metal Parts Based on Metal Powder Support

A metal powder and forming metal technology, which is applied in the field of surfacing and forming metal parts based on metal powder support, can solve the problems of difficult parts processing of cantilever structure, high cost of laser cladding and low cladding efficiency, etc., and achieves forming efficiency. High, conducive to wide popularization and application, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] see Figure 1 to Figure 3 , a method of surfacing metal parts supported by metal powder based on the present embodiment, which includes the following steps:

[0033] (1) According to the shape and structure of the metal parts to be formed, use 3D drawing software to create a 3D part model of the corresponding shape and structure, and convert the 3D part model into an STL format image file. The 3D drawing software can be UG, Pro-E, etc.

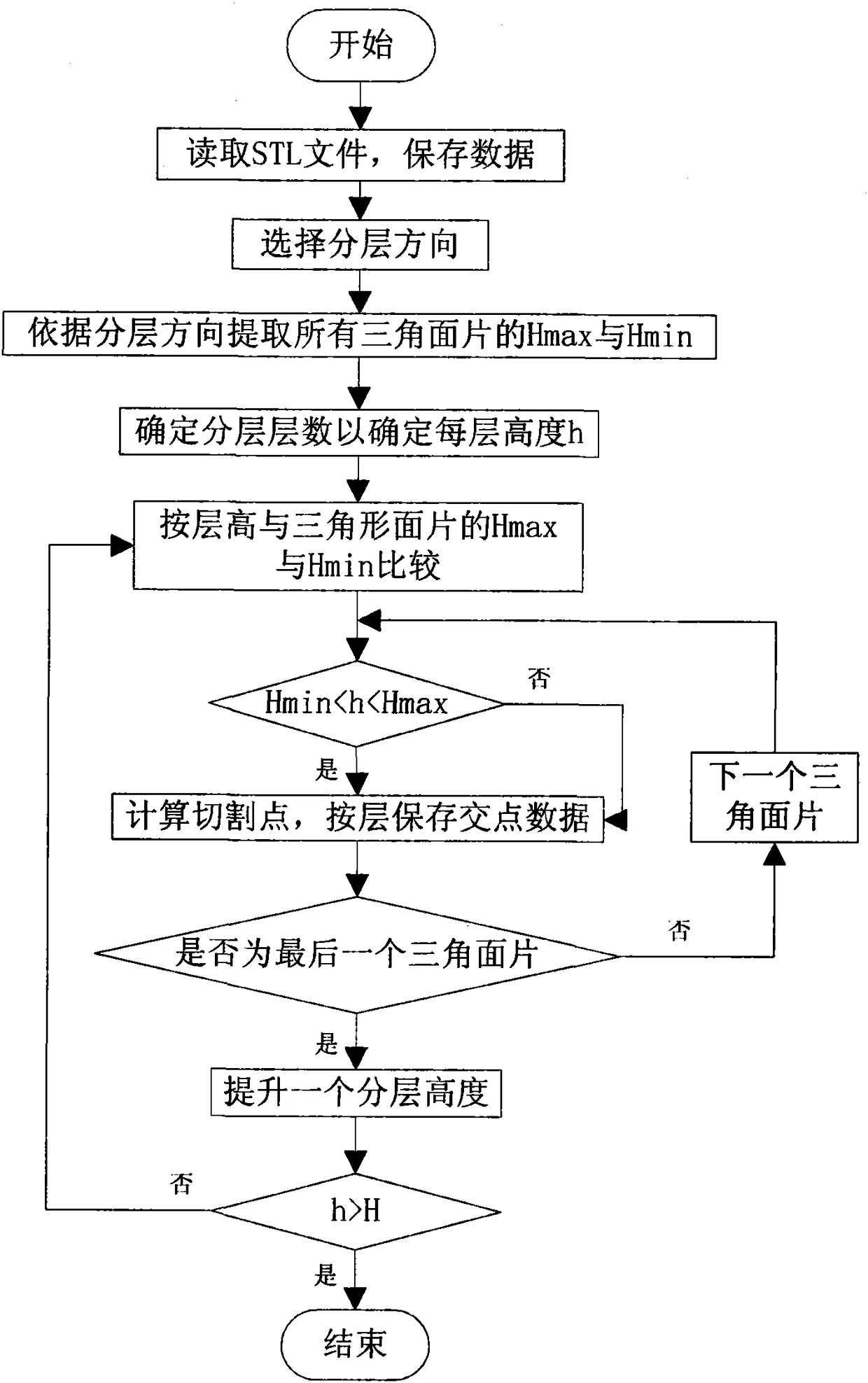

[0034] (2) Carry out hierarchical processing to the STL format map file, obtain layered overlay welding forming path trajectory data, and import the layered overlay welding forming path trajectory data into the control system of the metal overlay welding forming machine; see figure 2 Specifically, layering is carried out by the host computer software, including the following steps: (2.1) read all the triangle patch data of the STL format image file through the host computer software, and then select the direction to be layered, the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com