Functional anti-static wall surface paint and preparation method thereof

An anti-static, wall paint technology, applied in the direction of conductive paint, coating, epoxy resin paint, etc., can solve problems such as damage, circuit affecting product quality, troubles, etc., to achieve good decorative effect, good surface effect and covering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A functional antistatic wall paint provided by the present invention is composed of the following A system and B system with a mass ratio of 1:1:

[0035] System A

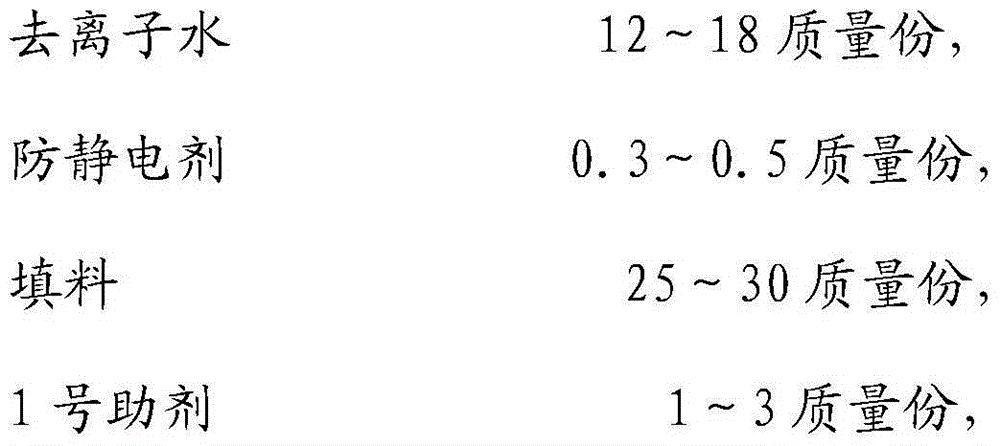

[0036] Pulping stage A1 system

[0037]

[0038] First, dissolve the antistatic agent with part of deionized water, then put the components into the dispersion tank in turn (adding while stirring), and stir and disperse at 1200rpm until the slurry fineness is less than 30um, and disperse normally for 60min. The aqueous solution of the electrostatic agent is in a stirring state in the dispersion tank, and is added slowly without interruption.

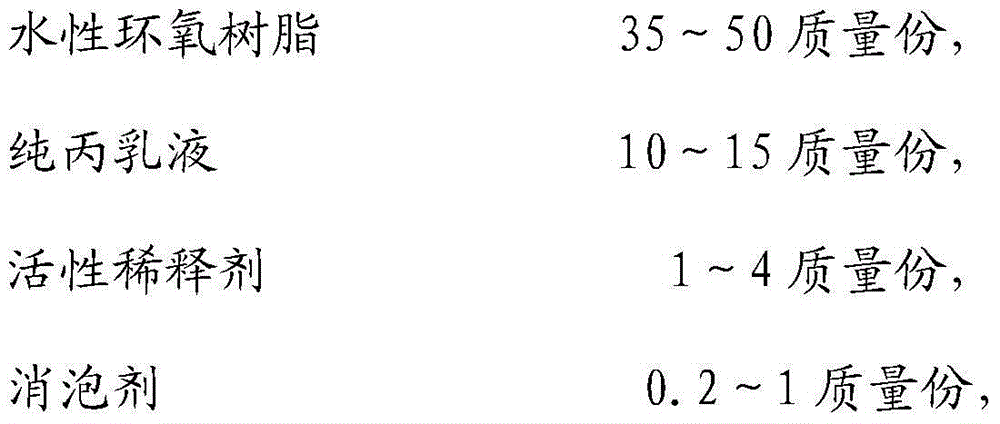

[0039] A2 system in the let-down stage

[0040]

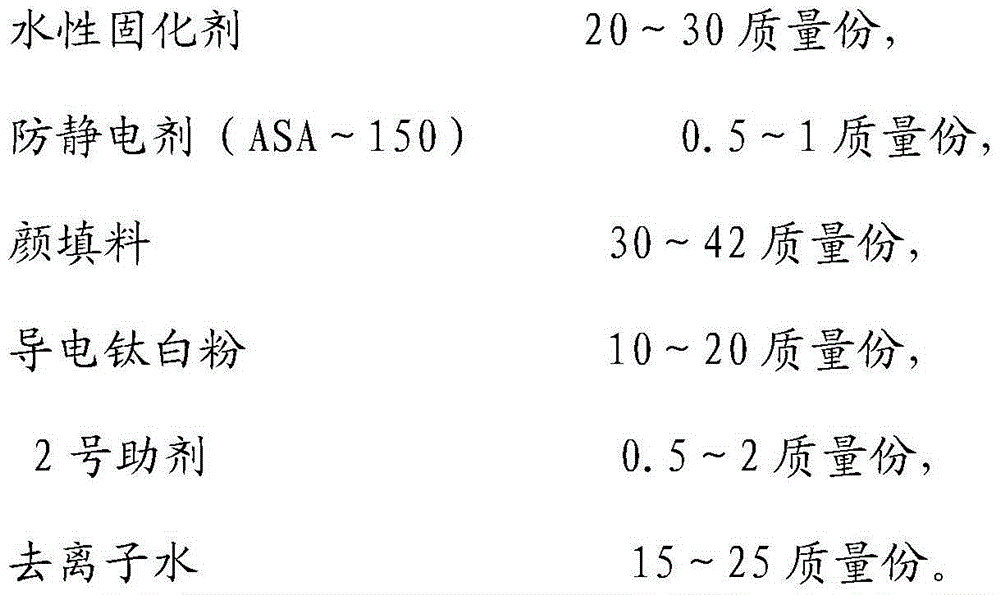

[0041] Put the above-mentioned component A2 in the let-down stage into the component A1 in the pulping stage, reduce the stirring speed to 600rpm, stir and disperse for 60min, filter and pack to get the component A of the functional antistatic wall paint. System B

[0042]

[0043]

[0044] First, disso...

Embodiment 2

[0047] Another functional antistatic wall paint provided by the present invention is composed of the following A system and B system with a mass ratio of 1:1:

[0048] System A

[0049] Pulping stage A1 system

[0050]

[0051]

[0052] First, dissolve the antistatic agent with part of deionized water, then put the components into the dispersion tank in turn (adding while stirring), and stir and disperse at 1200rpm until the slurry fineness is less than 30um, and disperse normally for 60min. The aqueous solution of the electrostatic agent is in a stirring state in the dispersion tank, and is added slowly without interruption.

[0053] A2 system in the let-down stage

[0054]

[0055] Put the above-mentioned component A2 in the let-down stage into the component A1 in the pulping stage, reduce the stirring speed to 600rpm, stir and disperse for 60min, filter and pack to get the component A of the functional antistatic wall paint. System B

[0056]

[0057]

[...

Embodiment 3

[0061] Another functional antistatic wall paint provided by the present invention is composed of the following A system and B system with a mass ratio of 1:1:

[0062] System A

[0063] Pulping stage A1 system

[0064]

[0065] Put the components into the dispersion tank in turn (adding while stirring), stir and disperse at 1200rpm until the fineness of the slurry is less than 30um, and disperse normally for 60min, wherein the aqueous solution of the antistatic agent is in a stirring state in the dispersion tank. Add slowly intermittently.

[0066] A2 system in the let-down stage

[0067]

[0068] Put the above-mentioned component A2 in the let-down stage into the component A1 in the pulping stage, reduce the stirring speed to 600rpm, stir and disperse for 60min, filter and pack to get the component A of the functional antistatic wall paint. System B

[0069]

[0070] First, dissolve the antistatic agent with some deionized water, then put the above raw materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com