Brown fluorubber compound and preparing method thereof

A fluororubber and rubber mixing technology, applied in the rubber field, can solve the problems of limited promotion and application, substandard rebound, complex processing technology, etc., and achieve the effects of simple preparation process, high resilience and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

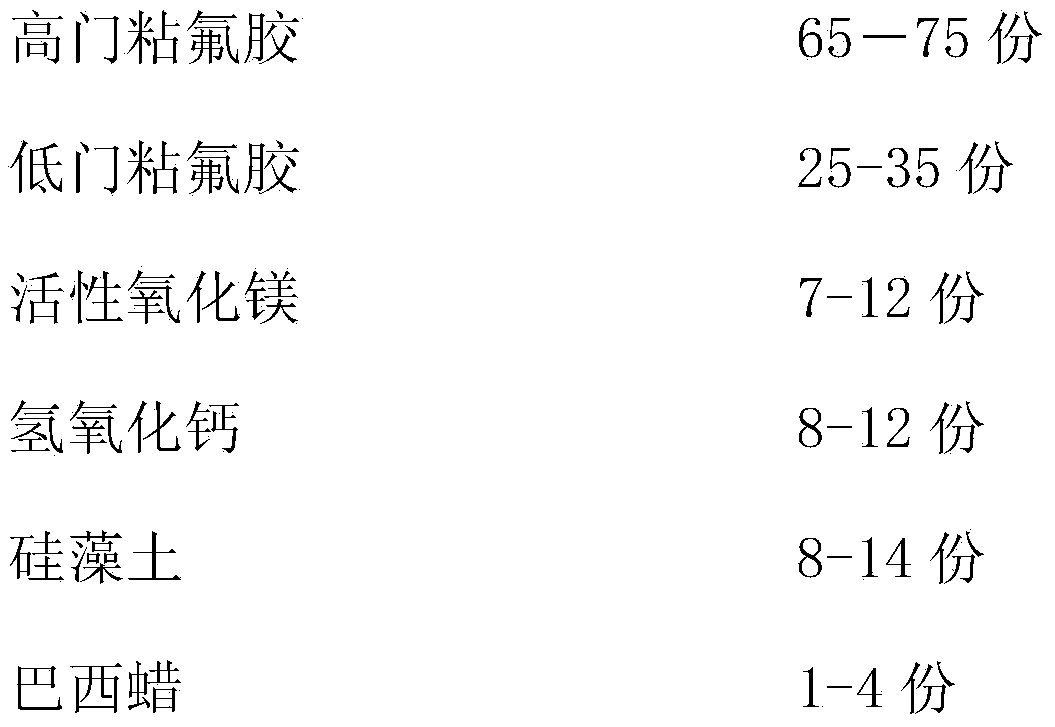

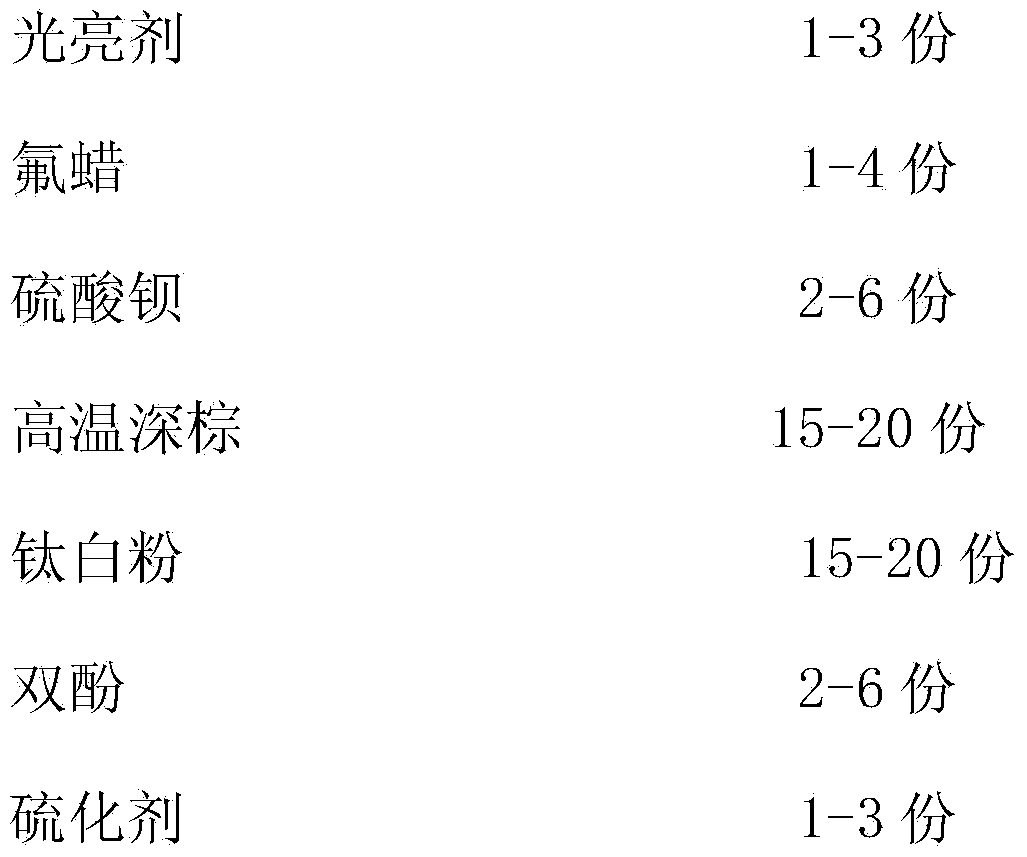

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of brown fluororubber compound, the preparation steps are as follows: first, 70 parts of high door viscose rubber and 30 parts of low door viscose fluorine rubber are added into the kneading internal mixer for masticating, heating the temperature to 105 ° C, stirring Speed 50-58r / min, stirring time 17min, then add 9 parts of active magnesium oxide, 9 parts of calcium hydroxide, 10 parts of diatomaceous earth, 3 parts of Brazilian wax, 2 parts of brightener, 3 parts of fluorine wax, 4 parts of sulfuric acid Barium, 18 parts of dark brown pigment, 16 parts of titanium dioxide, 3 parts of bisphenol, 2 parts of BPP vulcanizing agent, kneading and molding, the mixing temperature range is 155 ° C, the pressure is 12KN, the kneading mixer speed is 50r / min , The mixing time is 1.2h.

Embodiment 2

[0022] A preparation method of brown fluororubber compound, the preparation steps are as follows: first, 72 parts of high door viscose fluorine rubber and 30 parts of low door viscose fluorine rubber are added into the kneading internal mixer for masticating, heating the temperature to 108 ° C, stirring Speed 52r / min, stirring time 18min, then add 10 parts of active magnesium oxide, 11 parts of calcium hydroxide, 12 parts of diatomaceous earth, 2 parts of Brazilian wax, 2 parts of brightener, 4 parts of fluorine wax, 3 parts of barium sulfate, 17 parts of dark brown pigment, 16 parts of titanium dioxide, 4 parts of bisphenol, 2 parts of BPP vulcanizing agent, kneading and molding, the mixing temperature range is 160 ℃, the pressure is 13KN, the kneading mixer speed is 55r / min, mixing Refining time is 1.3h.

Embodiment 3

[0024] A preparation method of brown fluorine rubber compound, the preparation steps are as follows: first, 75 parts of high door viscose fluorine rubber and 30 parts of low door viscose fluorine rubber are added into the kneading internal mixer for masticating, heating the temperature to 115 ° C, stirring Speed 52r / min, stirring time 16min, then add 9 parts of active magnesium oxide, 11 parts of calcium hydroxide, 10 parts of diatomaceous earth, 3 parts of Brazilian wax, 2 parts of brightener, 2 parts of fluorine wax, 5 parts of barium sulfate, 17 parts of dark brown pigment, 16 parts of titanium dioxide, 4 parts of bisphenol, 2 parts of BPP vulcanizing agent, kneading and molding, the mixing temperature range is 162 ℃, the pressure is 13KN, the kneading internal mixer speed is 53r / min, mixing Refining time is 1.4h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength at break | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Compression set | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com