Combined treatment method for ammonia chloride waste water through rare earth extraction separation

A rare earth extraction, separation and treatment method technology, applied in the field of wastewater treatment, can solve the problems of paralysis of water treatment equipment system, affecting evaporation efficiency and product quality, and high operating costs, and achieves the effect of strengthening energy saving and environmental protection, reducing scaling and cleaning. The effect of low frequency, processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

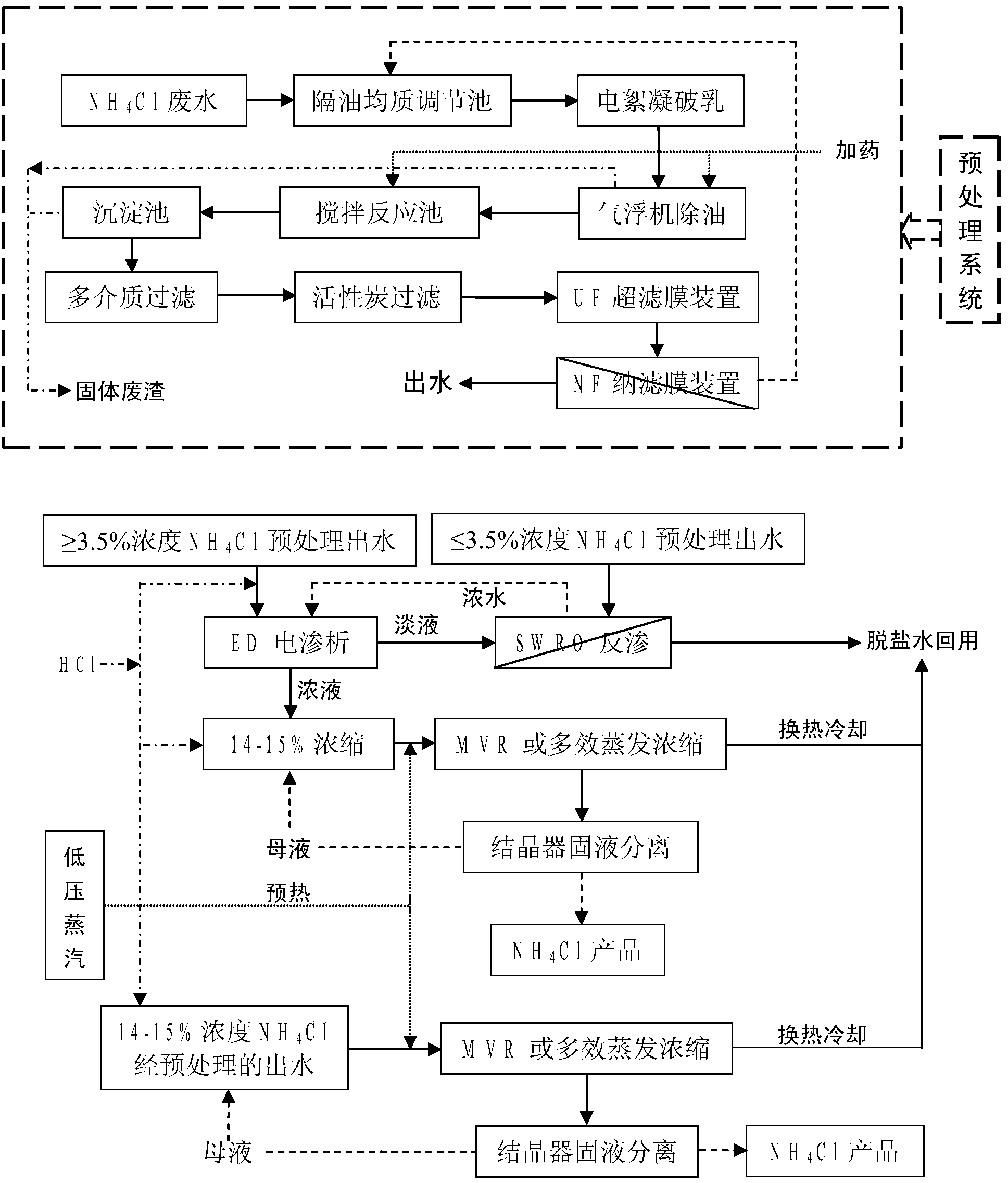

[0023] The NH4Cl wastewater with a concentration of 3.5% is discharged into the wastewater regulating tank, and after oil separation, homogenization and aeration are carried out in the regulating tank, continue to be processed in the following order (such as figure 2 shown):

[0024] a. Carry out electrocoagulation and demulsification, air flotation machine dosing and degreasing treatment to remove oily substances and suspended impurities in wastewater;

[0025] b. The waste water enters the air stirring reaction tank, adjusts the pH value to 7.0-7.5 with ammonia water, and then adds diammonium hydrogen phosphate and activated carbon powder to the waste water to precipitate and separate the calcium, magnesium and heavy metal ions in the waste water; the waste water enters the coagulation sedimentation tank and the aging tank continue processing;

[0026] c. Adsorption and filtration are carried out through a multi-media filter---activated carbon filter device;

[0027] d. U...

Embodiment 2

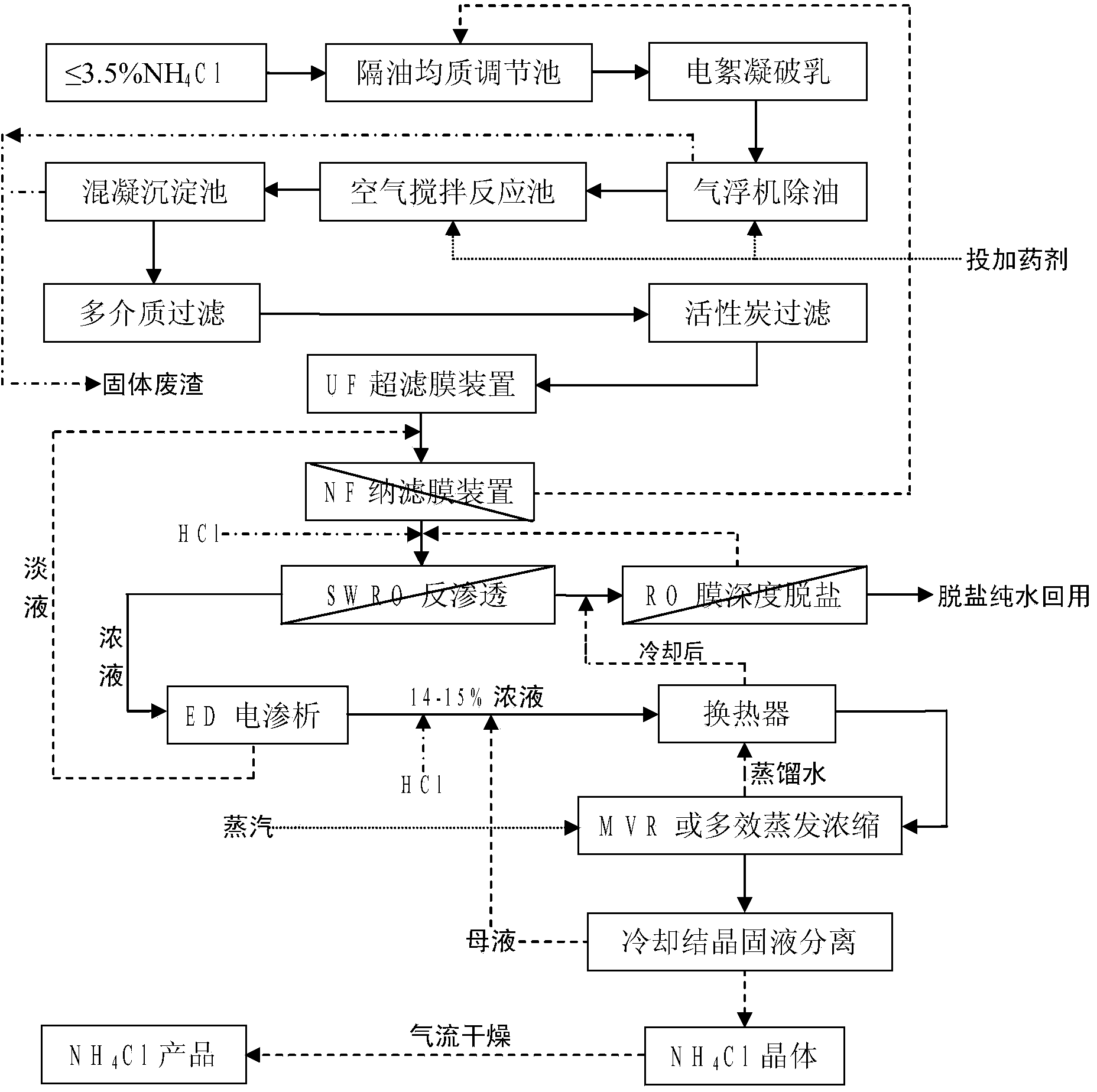

[0034] Containing NH4Cl wastewater with a concentration of 5.5% is discharged into a separate wastewater regulating tank, and oil separation, homogenization, and aeration are carried out in the regulating tank, and then processed in the following order (such as image 3 shown):

[0035] a. Perform electrocoagulation and demulsification, air flotation machine degreasing treatment to remove oily substances, calcium and magnesium ions and suspended solids in wastewater;

[0036] b. Wastewater enters the stirring reaction tank for treatment, adding ammonium bicarbonate to adjust the pH value to 7.0, continue to add soluble phosphate and activated carbon powder to the wastewater to remove calcium and magnesium ions, oily substances and heavy metal ions in the wastewater, and the wastewater enters the coagulation sedimentation tank Separation of precipitates and other solid impurities;

[0037] c. After the wastewater settles in the coagulation sedimentation tank for 3 hours, it en...

Embodiment 3

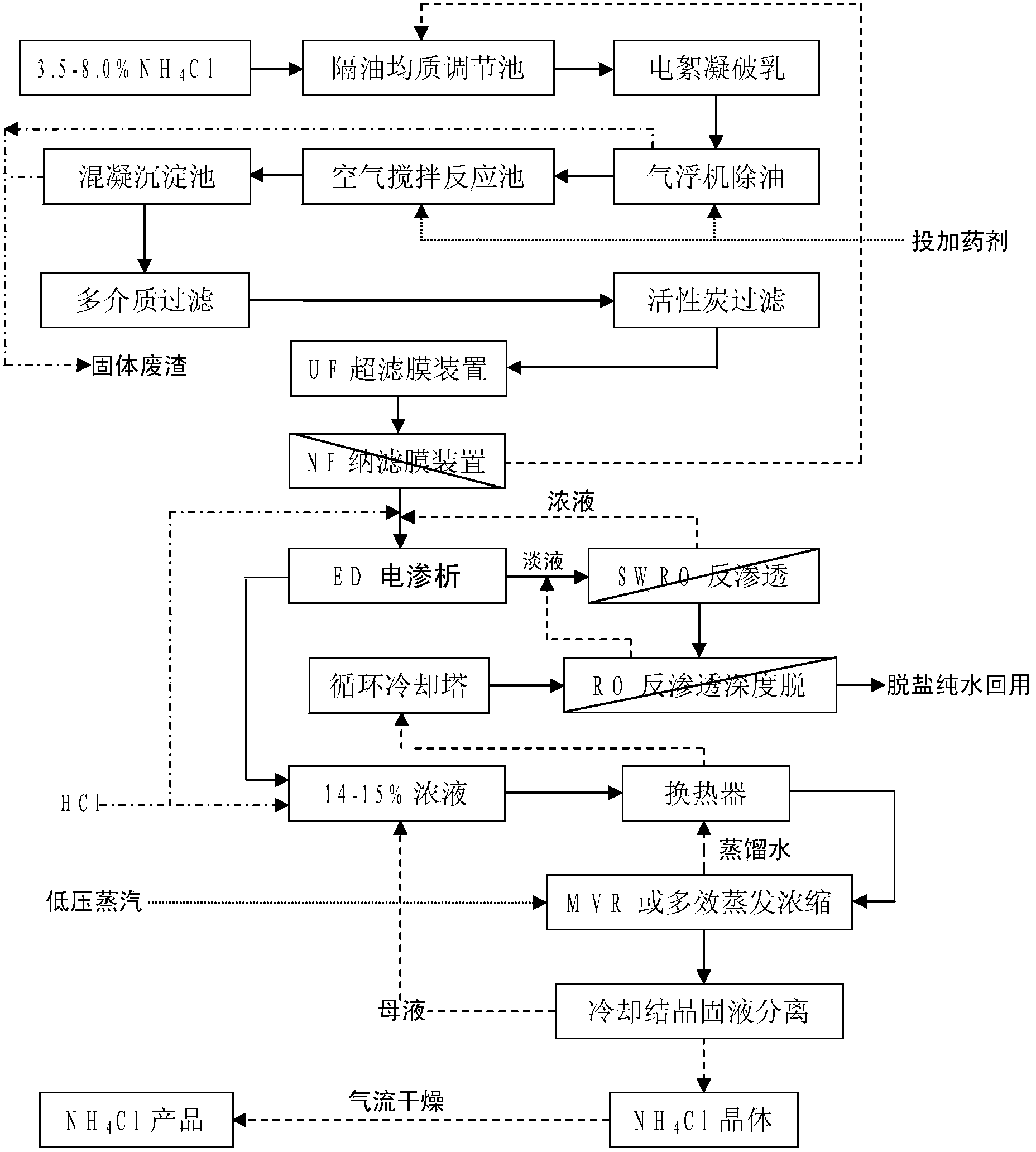

[0045] Discharge the NH4Cl-containing wastewater with a concentration of 15% into a separate wastewater regulating tank, and carry out oil separation, cooling and cooling, homogenization, and aeration in the regulating tank, and then process it in the following order (such as Figure 4 shown):

[0046] a. Conduct electrocoagulation demulsification, air flotation and oil removal treatment to remove oily substances, calcium and magnesium ions and suspended solids in wastewater;

[0047] b. Wastewater enters the stirring reaction tank, adding ammonia water to adjust the pH value to 7.0-7.5, then adding soluble phosphate and activated carbon powder to the wastewater to remove calcium and magnesium ions, oily substances and heavy metal ions, and entering the coagulation sedimentation tank for sedimentation reaction, keeping Sufficient residence time aging treatment;

[0048] c. Perform deep adsorption and filtration through a multi-media filter---activated carbon filter device;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com