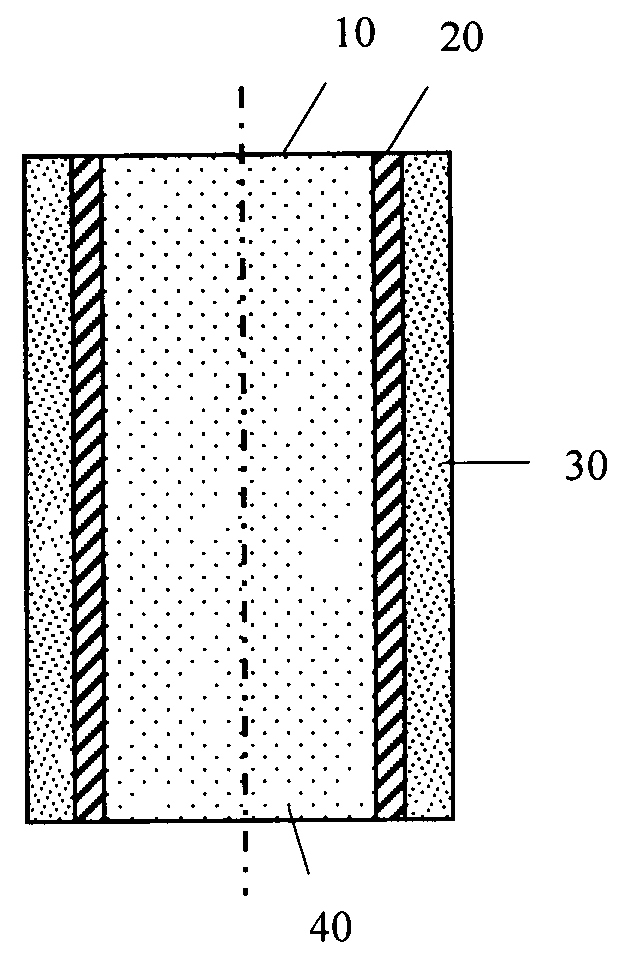

Method for preparing composite ceramic graphite electrode

A technology of graphite electrodes and composite ceramics, which is applied in the field of preparation of composite ceramic graphite electrodes, can solve the problems of low energy efficiency, easy loss, and the electrodes do not have anti-oxidation performance, and achieves dense electrode structure, high emission performance, and excellent anti-oxidation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of preparation method of composite ceramic graphite electrode is characterized in that comprising the steps of following order:

[0022] (1) Hot-pressed graphite rod:

[0023] ① Raw material selection: choose petroleum tar, needle coke, anthracite and coal tar pitch as raw materials, the selected quality standard is: the quality index of petroleum coke is, specific resistance Ω 2 / m, the specific gravity is 1.8g / m 3 , ash content ≤ 1.0%; the quality index of needle coke is: specific resistance Ω 2 / m, the specific gravity is 2.0g / m 3 , ash content ≤ 1.1%; the quality index of anthracite is: specific resistance Ω 2 / m, the specific gravity is 0.7g / m 3 , ash content ≤ 12.0%; the selected proportions are: 30% petroleum coke, 40% needle coke, 25% anthracite, and 5% coal tar pitch.

[0024] ②Calcination: The selected material is calcined under the condition of isolation of air, and the calcining temperature is 1300°C.

[0025] ③Batching: crush the selected material...

Embodiment 2

[0034] A kind of preparation method of composite ceramic graphite electrode is characterized in that comprising the steps of following order:

[0035] (1) Hot-pressed graphite rod:

[0036] ① Raw material selection: choose petroleum tar, needle coke, anthracite and coal tar pitch as raw materials, the selected quality standard is: the quality index of petroleum coke is, specific resistance Ω 2 / m, the specific gravity is 2.2g / m 3 , ash content ≤ 1.0%; the quality index of needle coke is: specific resistance Ω 2 / m, the specific gravity is 2.3g / m 3 , ash content ≤ 1.1%; the quality index of anthracite is: specific resistance Ω 2 / m, the specific gravity is 0.9g / m 3 , ash content ≤ 12.0%; selected ratios are: 30% petroleum coke, 30% needle coke, 30% anthracite, 10% coal tar pitch.

[0037] ②Calcination: The selected materials are calcined under the condition of isolation of air, and the calcining temperature is 1500°C.

[0038] ③Batching: crush the selected materials after ca...

Embodiment 3

[0046] A kind of preparation method of composite ceramic graphite electrode is characterized in that comprising the steps of following order:

[0047] (1) Hot-pressed graphite rod:

[0048] ① Raw material selection: choose petroleum tar, needle coke, anthracite and coal tar pitch as raw materials, the selected quality standard is: the quality index of petroleum coke is, specific resistance Ω 2 / m, the specific gravity is 2.0g / m 3 , ash content ≤ 1.0%; the quality index of needle coke is: specific resistance Ω 2 / m, the specific gravity is 2.1g / m 3 , ash content ≤ 1.1%; the quality index of anthracite is: specific resistance Ω 2 / m, the specific gravity is 0.8g / m 3 , ash content ≤ 12.0%; the selected proportions are: 50% petroleum coke, 40% needle coke, 5% anthracite, and 5% coal tar pitch.

[0049] ②Calcination: The selected material is calcined under the condition of isolation of air, and the calcining temperature is 1400°C.

[0050] ③Batching: crush the selected materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com