Cobalt powder preparation method

A technology of cobalt powder and lithium cobalt paper, which is applied in the field of chemical raw material production, can solve problems such as the impact on the health of workers, the increase in the amount of sulfuric acid, and the increase in production costs, and achieve the effects of high hardness, reduced production costs, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A kind of preparation method of cobalt powder is provided in the embodiment of the present invention, comprises the following steps:

[0023] (a), add sulfuric acid in lithium cobalt paper and carry out acidolysis, obtain cobalt sulfate solution;

[0024] (b), adjusting the pH value of the cobalt sulfate solution to 1-3, and then removing copper impurities;

[0025] (c), add the cobalt sulfate solution that removes copper impurity into hydrogen peroxide, then adjust the pH value to 2-5, press filter to remove impurities, and obtain a purified cobalt sulfate solution;

[0026] (d), purify the cobalt sulfate solution of purification, and react to make cobalt nitrate solution;

[0027] (e), heating and stirring the cobalt nitrate solution, and adding ammonium carbonate, and obtaining cobalt carbonate precipitation after the reaction;

[0028] (f) After the cobalt carbonate is dried, it is roasted in a hydrogen reduction system. The temperature of the roasting is 400-600°...

Embodiment 1

[0062] The preparation method of cobalt powder comprises the following steps:

[0063] (a), add sulfuric acid to lithium cobalt paper, the mass ratio of lithium cobalt paper and sulfuric acid is 1:0.5, acidolysis obtains cobalt sulfate solution; Pass cobalt sulfate solution through filter press, add sulfuric acid again in filter residue, filter residue and sulfuric acid The ratio is 1:2;

[0064] (b), adding mass percentage is 6% soda ash solution as neutralizer, the cobalt sulfate solution is adjusted to pH value to 1, then the cobalt sulfate solution is passed through the copper extraction box, removes copper impurity;

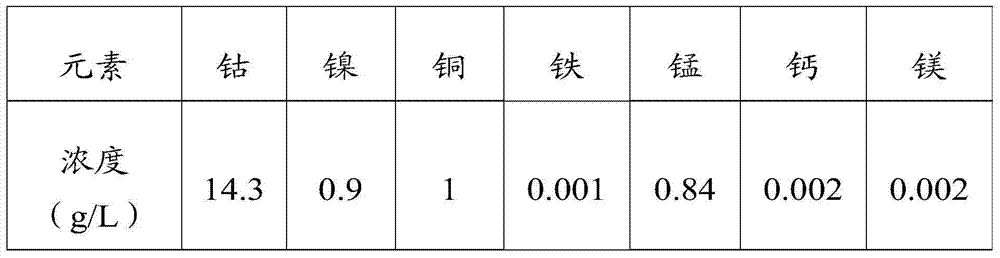

[0065] (c), the cobalt sulfate solution that removes copper impurity is added hydrogen peroxide, the addition of hydrogen peroxide is that the cobalt sulfate solution of every cubic meter adds 0.08kg hydrogen peroxide, then adding mass percent is 6% soda ash solution, adjusts pH value to 2, presses Impurities are removed by filtration to obtain purified cob...

Embodiment 2

[0073] The preparation method of cobalt powder comprises the following steps:

[0074] (a), add sulfuric acid to lithium cobalt paper, the mass ratio of lithium cobalt paper and sulfuric acid is 1:4, acidolysis obtains cobalt sulfate solution; Pass cobalt sulfate solution through filter press, add sulfuric acid again in filter residue, filter residue and sulfuric acid The ratio is 1:2.5;

[0075] (b), adding mass percent is 7% soda ash solution as a neutralizing agent, the cobalt sulfate solution is adjusted to a pH value of 2, and then the cobalt sulfate solution is passed through a copper extraction box to remove copper impurities;

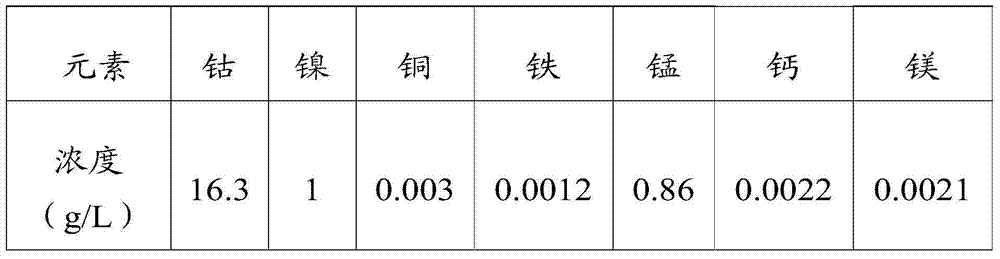

[0076] (c), the cobalt sulfate solution that removes copper impurity is added hydrogen peroxide, the addition of hydrogen peroxide is that the cobalt sulfate solution of every cubic meter adds 0.15kg hydrogen peroxide, then adding mass percent is 7% soda ash solution, adjusts pH value to 3.5, presses Impurities are removed by filtration to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com