Fructo-oligosaccharide lotus root vinegar and preparation method thereof

A technology of fructooligosaccharide and lotus root, which is applied in the field of fructooligosaccharide lotus root vinegar and its preparation, can solve the problems of single ingredients and general taste, and achieve the effects of increased nutritional components, pure flavor and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

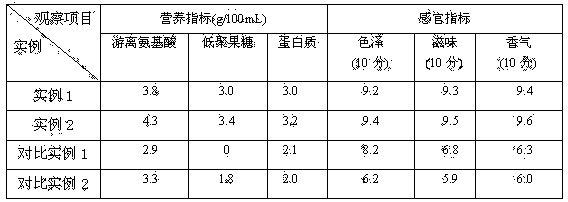

Examples

Embodiment 1

[0022] (1) Preparation of Jerusalem artichoke enzymatic solution: Take 95kg of fresh and cleaned Jerusalem artichoke and grind it with colloid, add 500kg of water to the slurry, mix and add enzyme activity 800,000 U / kg according to the weight ratio (g / kg) of raw materials. g of β-D-fructofuranosidase 0.60 g / kg, hydrolyzed at 45°C for 22 hours to obtain an enzymolyzed solution;

[0023] (2) Saccharification of lotus root slurry: grind 80kg of lotus root with a colloidal grinder, then mix it with the enzymatic solution obtained in step (1), and add amylase with an enzyme activity of 7000U / g according to the weight ratio (g / kg) of the raw material 0.50g / kg, 0.55g / kg of glucoamylase with enzyme activity of 8000 U / g, saccharification at 38°C for 8h;

[0024] (3) Preparation of wine mash: Add 0.40 g / Kg of Rhizopus oryzae and 0.60 g / Kg of Saccharomyces cerevisiae into the saccharification liquid obtained in step (2) according to the weight ratio (g / kg) of raw materials, and place at ...

Embodiment 2

[0028] (1) Preparation of Jerusalem artichoke enzymatic solution: Take 105kg of fresh and cleaned Jerusalem artichoke and grind it with colloid, add 550kg of water to the slurry, mix and add enzyme activity 800,000 U / kg according to the weight ratio (g / kg) of raw materials. g of β-D-fructofuranosidase 0.90 g / kg, hydrolyzed at 50°C for 25 hours to obtain the hydrolyzate;

[0029] (2) Saccharification of lotus root slurry: grind 100kg of lotus root with a colloidal grinder, then mix it with the enzymatic solution obtained in step (1), and add amylase with an enzyme activity of 7000U / g according to the weight ratio (g / kg) of the raw material 0.80g / kg, 0.85g / kg of glucoamylase with enzyme activity of 8000 U / g, saccharification at 44°C for 10h;

[0030] (3) Preparation of wine mash: Add 0.50 g / Kg of Rhizopus oryzae and 0.70 g / Kg of Saccharomyces cerevisiae into the saccharification liquid obtained in step (2) according to the weight ratio (g / kg) of raw materials, and place at 41°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com