Preparation method of submicron-level relaxor ferroelectric

A ferroelectric, sub-micron technology, applied in the field of preparation of sub-micron relaxor ferroelectrics, can solve the problems of weakening the electrical properties of ceramics, poor frequency stability, poor temperature stability, etc., and achieve excellent relaxor ferroelectric behavior , high density, fine and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

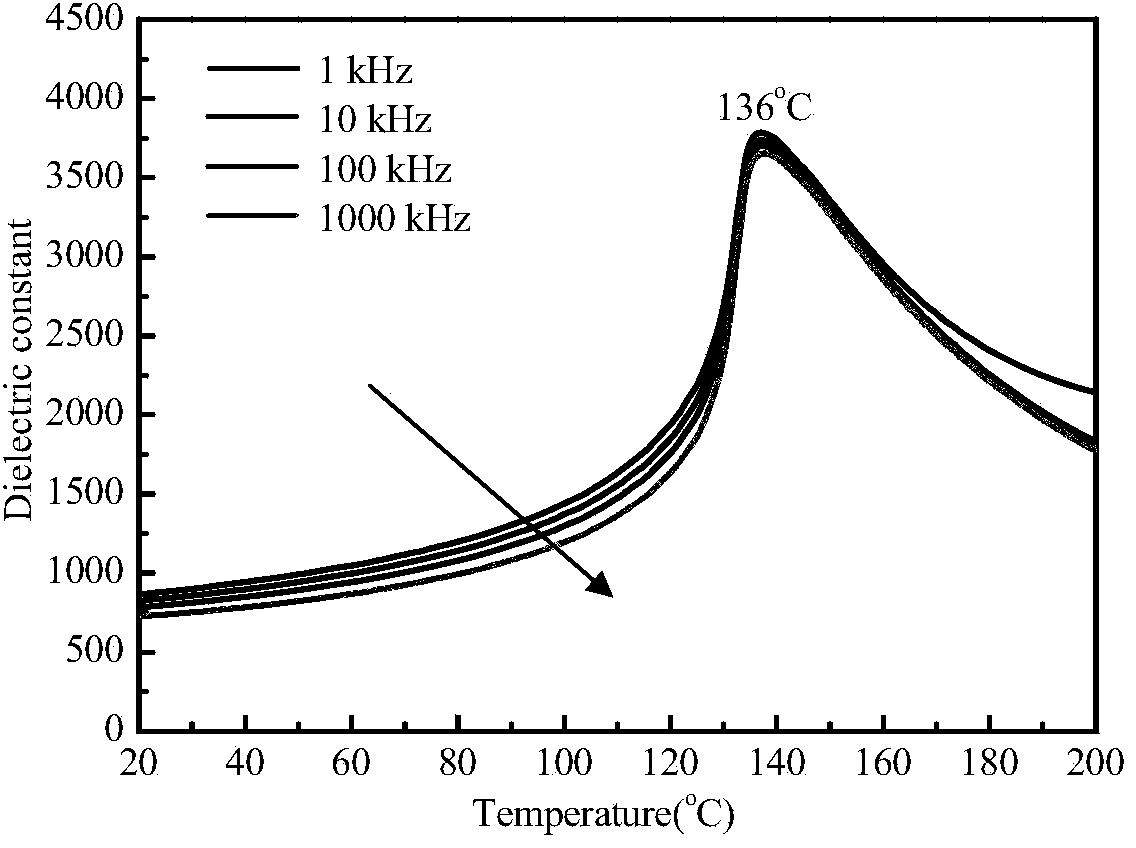

Embodiment 1

[0038] 1) First weigh BaCl according to the molar ratio of 0.9:0.1:0.03 2 2H 2 O, CaCl 2 and Bi(NO 3 ) 3 and respectively configured into solutions, mixed and left to stand to obtain a mixed solution A;

[0039] 2) Press Ca 2+ with Ti 4+ The molar ratio is 0.1:1, the TiCl 4 Add dropwise to mixed solution A and stir to make mixed solution B. At the same time, adjust the pH value of mixed solution B to be greater than 14 by NaOH, and stir until mixed solution B becomes white and viscous to obtain Ba 0.9 Ca 0.1 TiO 3 -0.03Bi powder precursor;

[0040] 3) the prepared Ba 0.9 Ca 0.1 TiO 3 Pour the -0.03Bi powder precursor into a hydrothermal kettle with a filling ratio of 70%, and keep it in a hydrothermal environment at 240°C for 12h to obtain Ba 0.9 Ca 0.1 TiO 3 -0.03Bi powder, the powder is washed and precipitated, and finally the green body is formed;

[0041] 4) Microwave sintering the formed green body, the sintering temperature is 1200°C, the holding time is ...

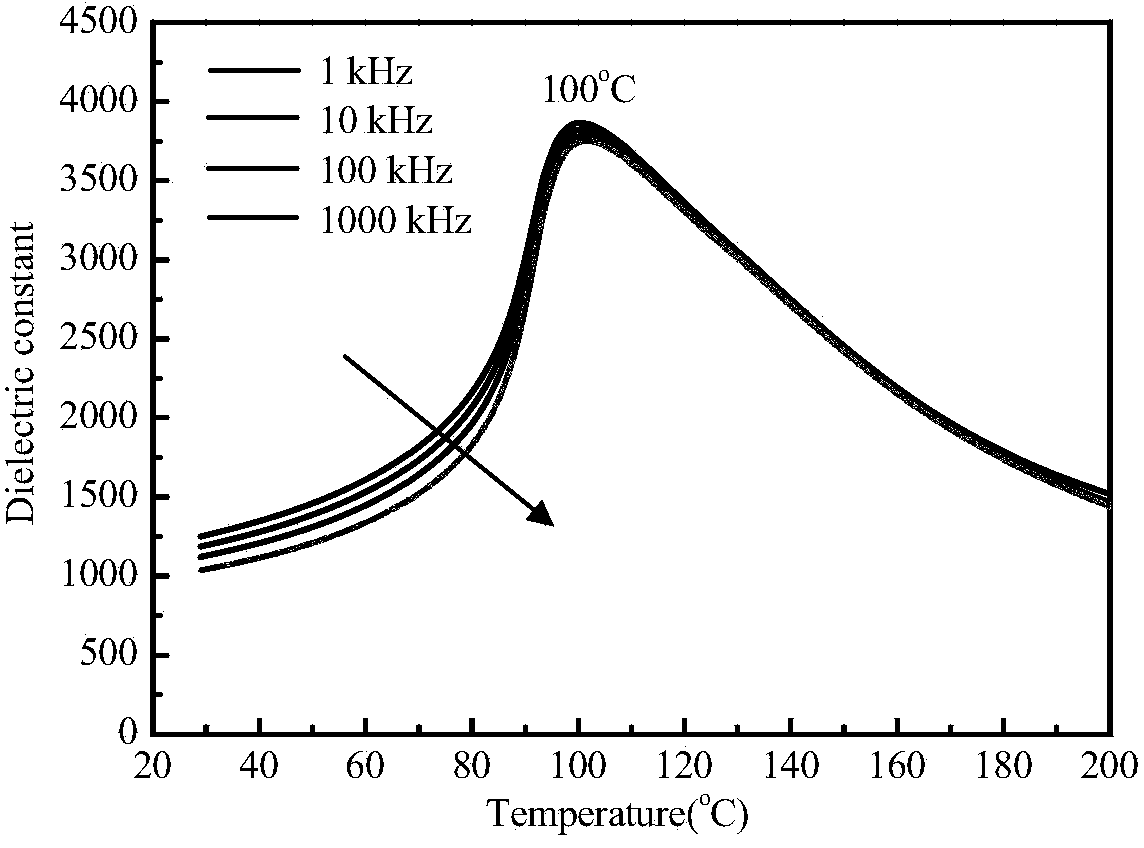

Embodiment 2

[0043] 1) First weigh BaCl according to the molar ratio of 0.9:0.1:0.03:0.03 2 2H 2 O, CaCl 2 ZrOCl 2 ·8H 2 O and Bi(NO 3 ) 3 and respectively configured into solutions, mixed and left to stand to obtain a mixed solution A;

[0044] 2) Press Ca 2+ with Ti 4+ The molar ratio is 0.1:0.97, the TiCl 4 Add dropwise to mixed solution A and stir to make mixed solution B. At the same time, adjust the pH value of mixed solution B to be greater than 14 by NaOH, and stir until mixed solution B becomes white and viscous to obtain Ba 0.9 Ca 0.1 Ti 0.97 Zr 0.03 o 3 -0.03Bi powder precursor;

[0045] 3) the prepared Ba 0.9 Ca 0.1 Ti 0.97 Zr 0.03 o 3 Pour the -0.03Bi powder precursor into a hydrothermal kettle with a filling ratio of 70%, and keep it in a hydrothermal environment at 180°C for 12h to obtain Ba 0.9 Ca 0.1 Ti 0.97 Zr 0.03 o 3 -0.03Bi powder, the powder is washed and precipitated, and finally the green body is formed;

[0046] 4) Microwave sintering the fo...

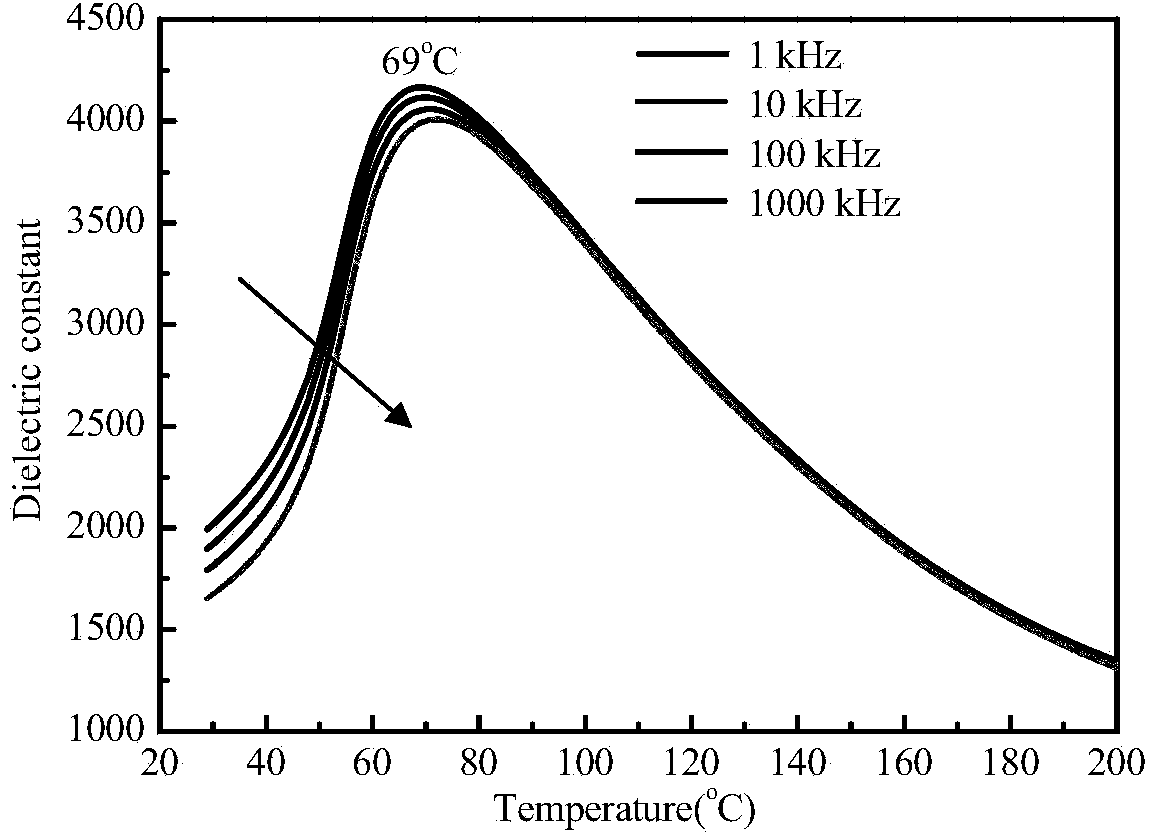

Embodiment 3

[0048] 1) First weigh BaCl according to the molar ratio of 0.9:0.1:0.06:0.03 2 2H 2 O, CaCl 2 ZrOCl 2 ·8H 2 O and Bi(NO 3 ) 3 and respectively configured into solutions, mixed and left to stand to obtain a mixed solution A;

[0049] 2) Press Ca 2+ with Ti 4+ The molar ratio is 0.1:0.94, the TiCl 4 Add dropwise to mixed solution A and stir to make mixed solution B. At the same time, adjust the pH value of mixed solution B to be greater than 14 by NaOH, and stir until mixed solution B becomes white and viscous to obtain Ba 0.9 Ca 0.1 Ti 0.94 Zr 0.06 o 3 -0.03Bi powder precursor;

[0050] 3) the prepared Ba 0.9 Ca 0.1 Ti 0.94 Zr 0.06 o3 Pour the -0.03Bi powder precursor into a hydrothermal kettle with a filling ratio of 80%, and keep it in a hydrothermal environment at 150°C for 15h to obtain Ba 0.9 Ca 0.1 Ti 0.94 Zr 0.06 o 3 -0.03Bi powder, the powder is washed and precipitated, and finally the green body is formed;

[0051] 4) Microwave sintering the form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com