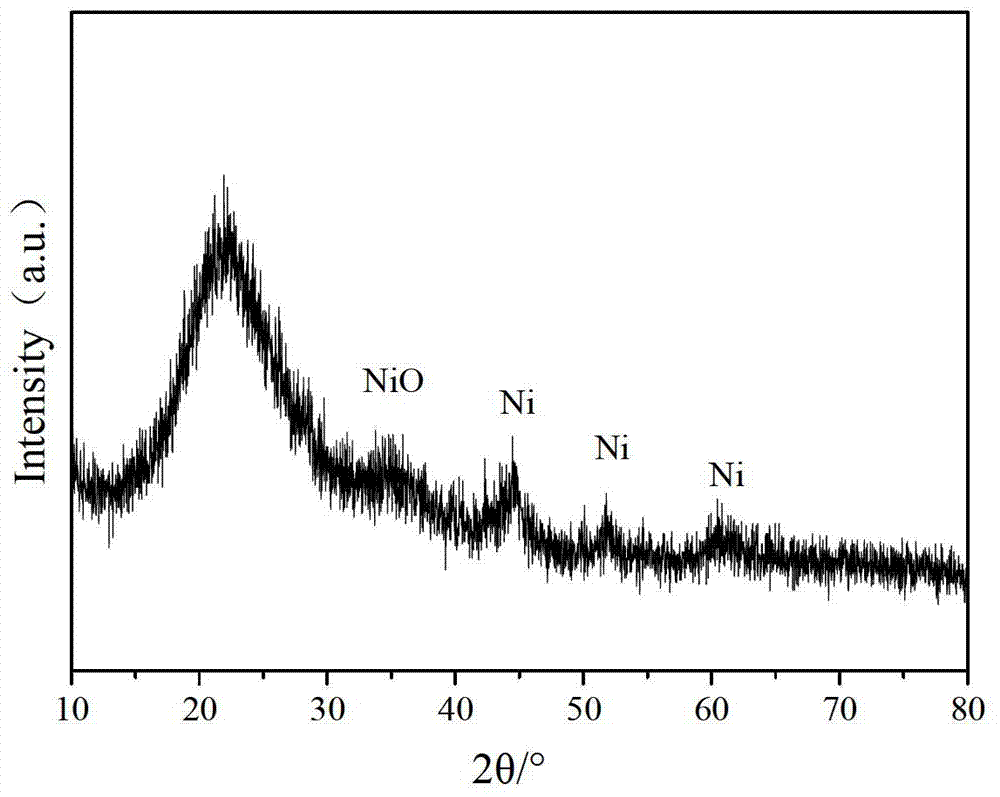

Silica composite doped with metal and/or its oxide in situ and use thereof

A technology of silica and oxides, applied in the direction of hydrocarbon production from carbon oxides, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as reduced catalytic activity and poor thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The method for preparing the silicon dioxide compound doped with metal or / and its oxide as described above in the present invention specifically includes the following steps:

[0031] (1) Prepare a nickel salt solution with a mass percentage concentration of 1wt% to 20wt%, a mass percentage of a rare earth metal salt solution with a mass percentage of 0wt% to 5wt%, a mass percentage of a "rare metal" salt solution with a mass percentage of 0wt% to 10wt%, and the mass The percentage is 0wt%~5wt% alkali metal salt solution;

[0032] (2) First, place the template agent, "alkali source" and "silicon source" in the reactor at room temperature (20°C ~ 40°C, the same below) and under stirring conditions, and continue stirring for 0.5 hours to After 24 hours, add the "metal source" solution dropwise and continue to stir for 0.5 to 24 hours to obtain an emulsion; finally, react the obtained emulsion with hydrothermal reaction at 80°C to 180°C for 12 to 100 hours, and quench to ...

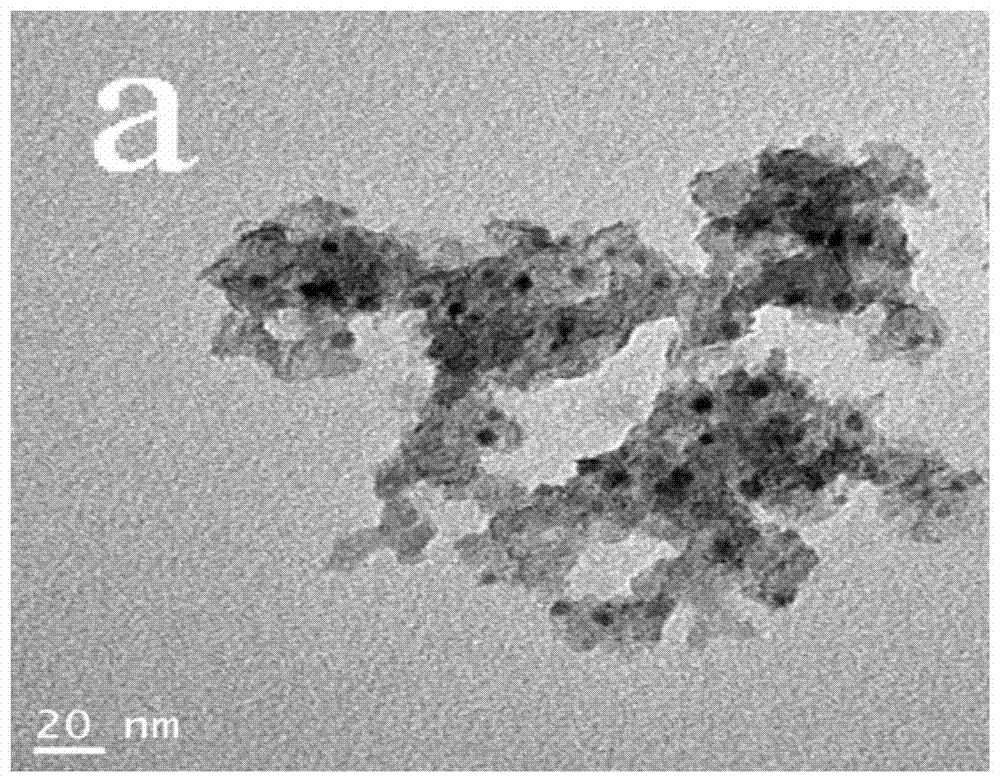

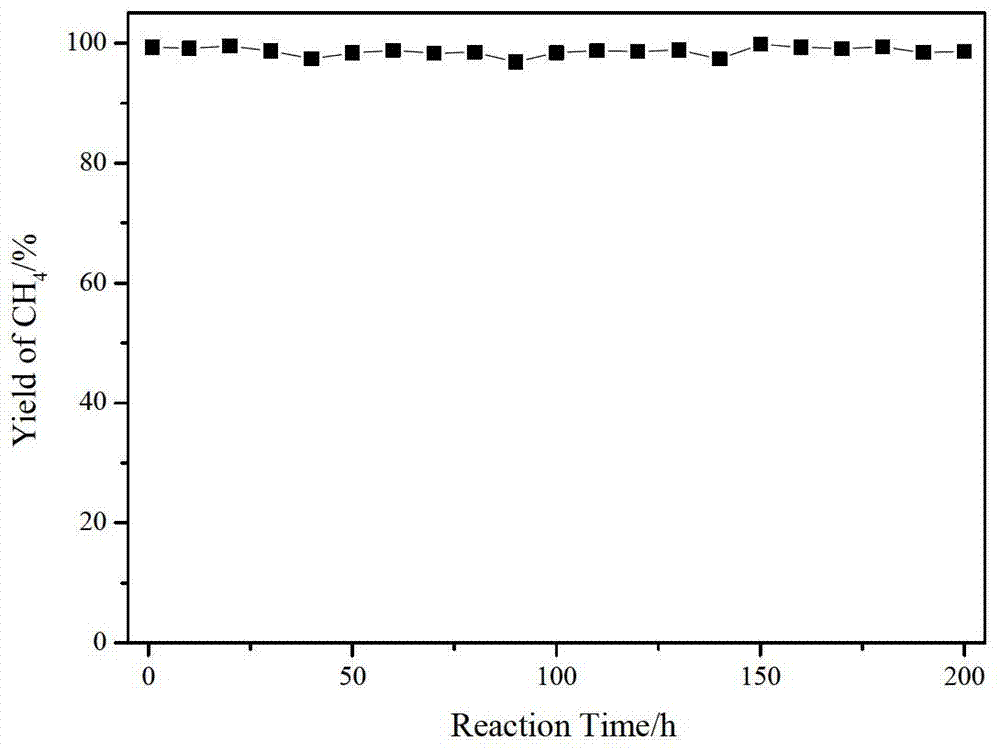

Embodiment 1

[0049] Weigh 2.428 g of cetyltrimethylammonium bromide (template) and dissolve it in deionized water at 40°C to obtain an aqueous template solution. Weigh 1.619g of nickel nitrate hexahydrate and dissolve it in 20ml of deionized water to prepare an aqueous solution of nickel nitrate. Dissolve 0.447g NaOH in 10ml deionized water to obtain NaOH aqueous solution.

[0050] The obtained NaOH aqueous solution was slowly dropped into the above-mentioned template aqueous solution under vigorous stirring. Under vigorous stirring, 11.565 g of ethyl orthosilicate was added dropwise into the aqueous template solution. After the dropwise addition, stir vigorously for 2h, then start to slowly add nickel nitrate aqueous solution dropwise, after the dropwise addition, stir vigorously at room temperature for 2h, move the product to a hydrothermal reaction kettle, and crystallize at 120°C for 72h. Then it was rapidly cooled to room temperature, filtered, and the filter cake was washed until n...

Embodiment 2

[0054] Replace the nickel nitrate in embodiment 1 with lanthanum nitrate and nickel nitrate, obtain the metal nickel of doping 10wt% or / and its oxide compound and the metal lanthanum of doping 1wt% or / and its oxide with similar method in embodiment 1 compound of silica (abbreviated as catalyst B).

[0055] Catalyst evaluation method is identical with embodiment 1, and catalyst B is under 1.5Mpa, space velocity 12000h -1 , the conversion rate of carbon monoxide is 100%, and the selectivity of methane is over 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com