Maggot oil extraction by ultrasonic-assisted extraction method and maggot oil

A kind of grain insect oil and ultrasonic technology, applied in the direction of fat oil/fat production, chemical/physical/physicochemical process of energy application, fat generation, etc., can solve the problem of unsuitable for large-scale production, low energy consumption, and the amount of residual oil in cake residue Advanced problems, to achieve the effect of maintaining functional properties and nutritional value, reducing the number of extractions, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

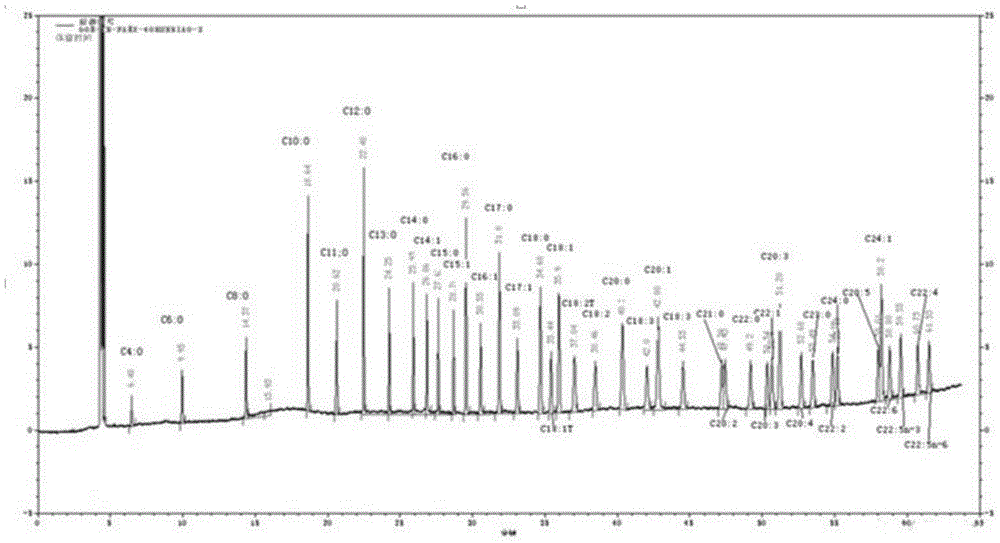

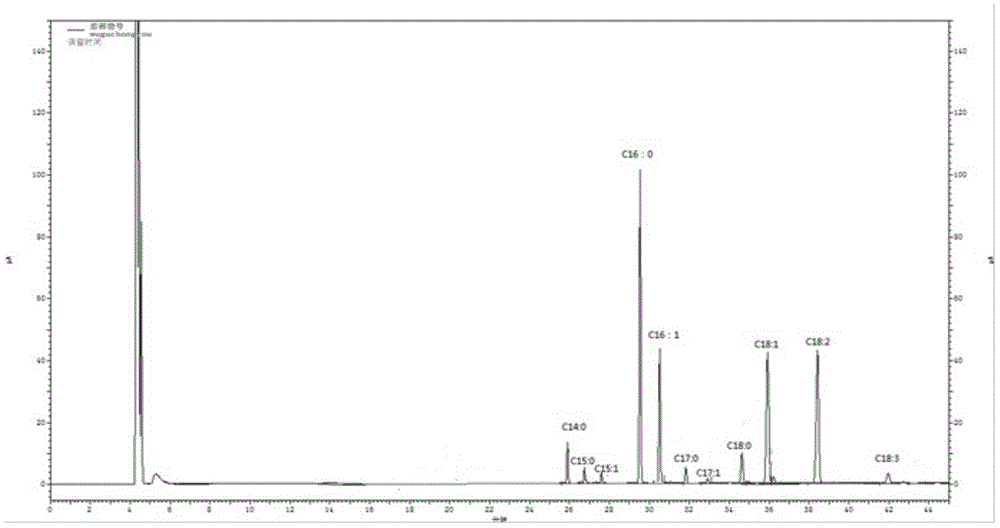

Image

Examples

Embodiment 1

[0022] (1) Drying, under the conditions of vacuum degree of 0.06MPa and temperature of -45°C, freeze-dry for 48 hours; moisture content is less than 8%.

[0023] (2) Extraction, crush the dried grain worms with a universal grinder, sieve, take out the 50-mesh grain insect powder, add a certain amount of the grain insect powder into the reaction device, and add the solvent according to 8 times the weight of the grain insect powder, Extraction temperature 25°C, ultrasonic power 300w, ultrasonic extraction 25min, soak for 24 hours, suction filtration, add 3 times the amount of solvent to the filter residue according to the weight ratio, extraction temperature 25°C, ultrasonic power 300w, ultrasonic extraction 25min, soak for 24 hours, suction filtration , combined filtrate.

[0024] (3) Collect, centrifuge the suction-filtered mixture at 4000r / min for 15min, and obtain the supernatant as the extract; use a rotary evaporator to evaporate the obtained supernatant under reduced pres...

Embodiment 2

[0033] (1) Drying, under the conditions of vacuum degree of 0.08MPa and temperature of -50°C, freeze-dry for 24 hours; the moisture content is less than 10%.

[0034] (2) Extraction, crush the dried grain worm with a universal grinder, sieve, take out the 80-mesh grain insect powder, add a certain amount of the grain insect powder into the reaction device, and add the solvent according to 5 times the weight of the grain insect powder, The extraction temperature is 30°C, the ultrasonic power is 250w, the ultrasonic extraction is for 15 minutes, soaked for 24 hours, and suction filtered.

[0035] (3) Collect, centrifuge the filtrate obtained by suction filtration at 3000r / min for 20min, and obtain the supernatant as the extract; use a rotary evaporator to evaporate the obtained supernatant under reduced pressure to remove the solvent, and recover the solvent at the same time .

[0036] (4) Drying. Finally, vacuum-dry the grain insect oil from which the solvent has been removed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com