Surface modification method for carbon fiber powder

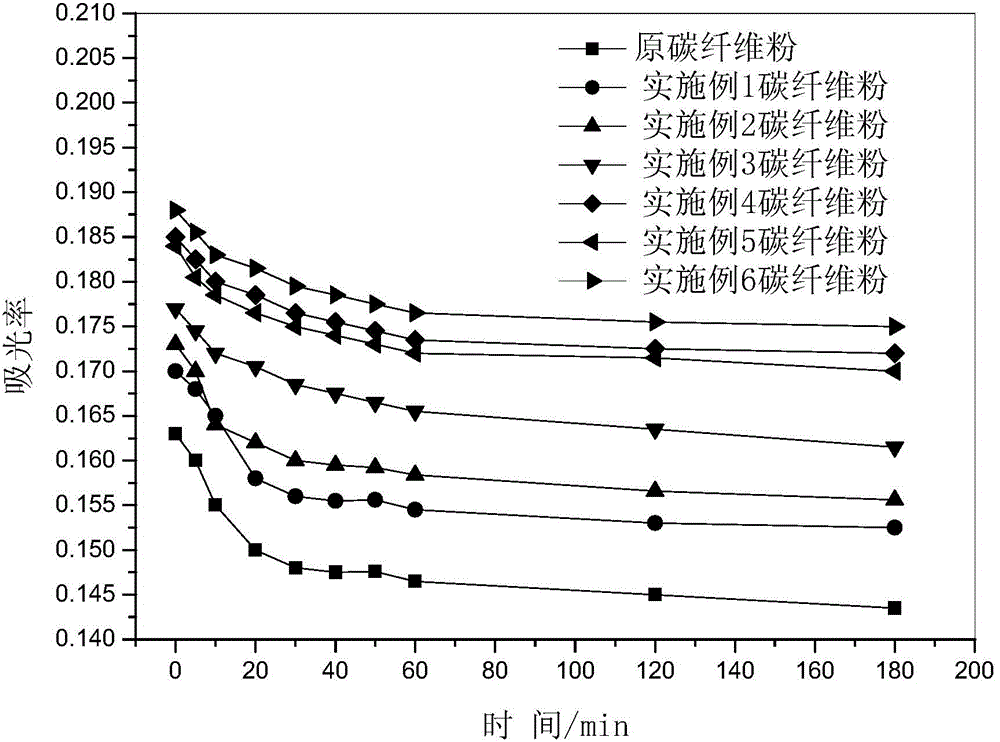

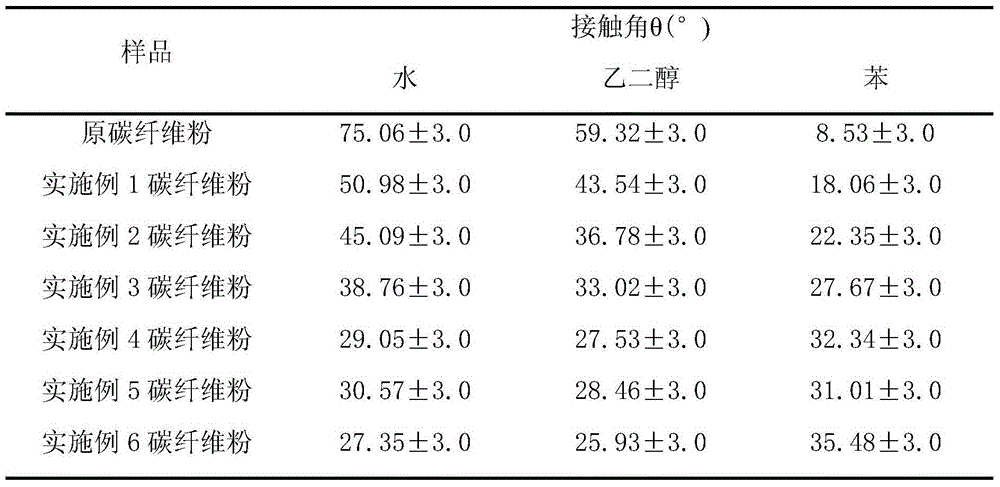

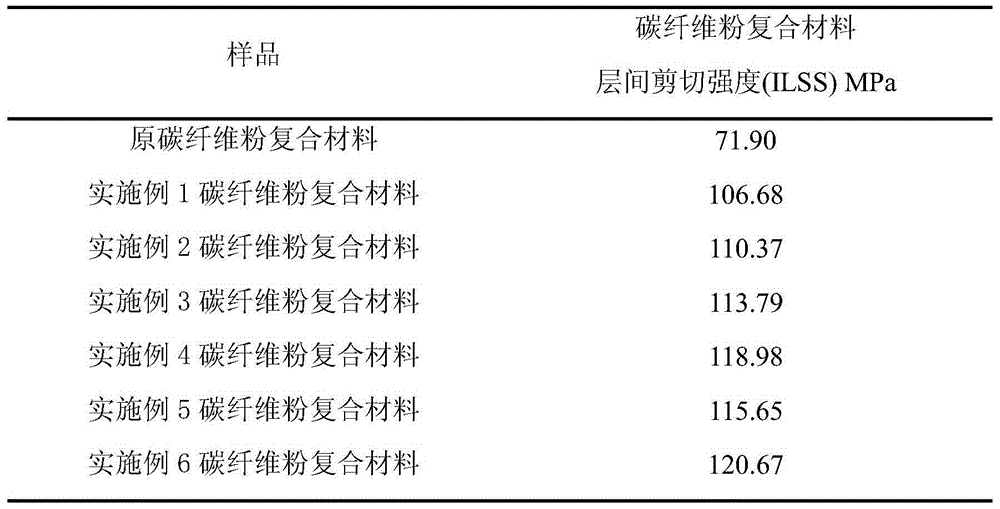

A carbon fiber powder and surface modification technology, applied in the directions of carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of poor wettability and dispersion stability, high inertness, limiting the advantages of carbon fiber powder, etc., and achieve the effect of improving related performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for modifying the surface of carbon fiber powder, comprising the steps of:

[0017] (1) Air burning pretreatment of carbon fiber powder: Weigh 100g of raw carbon fiber powder, place it in a 300ml porcelain crucible, put it in a muffle furnace, raise the temperature from room temperature to 350°C, and keep it warm for 5min;

[0018] (2) Immerse the pretreated carbon fiber powder in the oxidizing solution for surface modification: use a sulfuric acid solution with a molar concentration of 0.5mol / L to prepare a sodium chlorate-sulfuric acid oxidation solution with a molar concentration ratio of sodium chlorate and sulfuric acid of 1:1.0 Liquid 500ml; Weigh 40g of carbon fiber powder after step (1) pretreatment and put it into a 1000ml beaker, add 500ml sodium chlorate-sulfuric acid oxidation solution to make the mass concentration of carbon fiber powder be 80g / L; Heating to boiling, and reacting for 120min, then naturally cooling to room temperature;

[0019] (3)...

Embodiment 2

[0021] A method for modifying the surface of carbon fiber powder, comprising the steps of:

[0022] (1) Air burning pretreatment of carbon fiber powder: Weigh 100g of raw carbon fiber powder, place it in a 300ml porcelain crucible, put it into a muffle furnace, raise the temperature from room temperature to 500°C, and keep it warm for 20min;

[0023] (2) Immerse the pretreated carbon fiber powder in the oxidizing solution for surface modification: use a sulfuric acid solution with a molar concentration of 0.5mol / L to prepare a sodium chlorate-sulfuric acid oxidation solution with a molar concentration ratio of sodium chlorate and sulfuric acid of 1:1.0 Liquid 500ml; Weigh 40g of carbon fiber powder pretreated in step (1) and put it into a 1000ml beaker, add 500ml of sodium chlorate-sulfuric acid oxidation solution to make the mass concentration of carbon fiber powder 80g / L, and mix the oxidation solution with stirring Heating to boiling, and reacting for 120min, then naturally...

Embodiment 3

[0026] A method for modifying the surface of carbon fiber powder, comprising the steps of:

[0027] (1) Carry out air burning pretreatment on carbon fiber powder: weigh 100g of raw carbon fiber powder, put it in a 300ml porcelain crucible, put it into a muffle furnace, raise the temperature from room temperature to 400°C, and keep it warm for 10min;

[0028] (2) Immerse the pretreated carbon fiber powder into the oxidizing solution for surface modification: use a sulfuric acid solution with a molar concentration of 1.5mol / L to prepare potassium permanganate with a sulfuric acid molar concentration ratio of 1:2.0- Sulfuric acid oxidation solution 500ml; Weigh 20g of carbon fiber powder after step (1) pretreatment and put it into a 1000ml beaker, add 500ml potassium permanganate-sulfuric acid oxidation solution to make the mass concentration of carbon fiber powder be 40g / L; under stirring condition Heat the oxidizing solution to boiling, and react for 90 minutes, then naturally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com