A kind of ultra-low temperature resistant polypropylene composite material and preparation method thereof

A technology of composite material and polypropylene, which is applied in the field of ultra-low temperature-resistant polypropylene composite materials and its preparation, can solve the problems of poor low-temperature toughness, etc., and achieve the effects of excellent low-temperature impact performance, good toughening effect, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

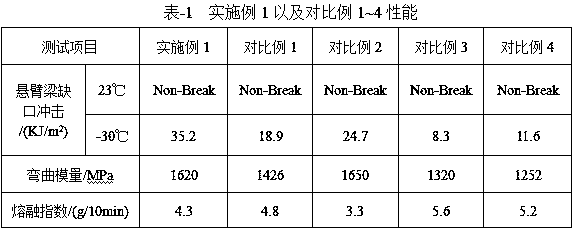

Embodiment 1

[0069] (1) Preparation of cross-linked ethylene-α-olefin copolymer

[0070] 100 parts of POE 7447, 0.65 parts of crosslinking initiator DCP, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 0.1 part of lubricant EBS, 0.05 part of lubricant calcium stearate, 0.05 part of lubricant white oil 36 #Put it in a high-speed mixer for high-speed mixing for 2 minutes. The speed of the high-speed mixer is 200 rpm and the temperature is 25°C. The mixed mixture is fed into a twin-screw extruder for melt cross-linking extrusion, stranding, and pelletizing to finally obtain a cross-linked ethylene-alpha olefin copolymer. The temperature of the twin-screw extruder is 30°C, 40°C, 100°C, 105°C, 105°C, 108°C, 108°C, 110°C from the feeding section to the machine head, the length-to-diameter ratio of the twin-screw is 25, and the screw speed is at 100 rpm.

[0071] (2) Preparation of ultra-low temperature resistant polypropylene composites

[0072] First, put 12 parts of the cross-lin...

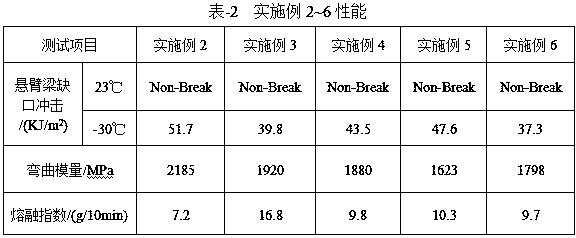

Embodiment 2

[0088] (1) Preparation of cross-linked ethylene-α-olefin copolymer

[0089]100 parts of POE 8150, 2.75 parts of crosslinking initiator TBPB, 0.35 parts of antioxidant 1010, 0.15 parts of antioxidant 168, 0.25 parts of lubricant EBS, 0.1 part of lubricant calcium stearate, 0.15 parts of lubricant white oil 36 #Put it in a high-speed mixer for high-speed mixing for 5 minutes. The speed of the high-speed mixer is 300 rpm and the temperature is 30°C. The mixed mixture is fed into a twin-screw extruder for melt cross-linking extrusion, stranding, and pelletizing to finally obtain a cross-linked ethylene-alpha olefin copolymer. The temperature of the twin-screw extruder is 30°C, 40°C, 100°C, 105°C, 105°C, 108°C, 108°C, 110°C from the feeding section to the machine head, the length-to-diameter ratio of the twin-screw is 25, and the screw speed is 130 rpm.

[0090] (2) Preparation of ultra-low temperature resistant polypropylene composites

[0091] First, put 22 parts of the cross-...

Embodiment 3

[0093] (1) Preparation of cross-linked ethylene-α-olefin copolymer

[0094] 100 parts of POE 7447, 0.87 parts of crosslinking initiator BPO, 0.18 parts of antioxidant 1010, 0.12 parts of antioxidant 168, 0.16 parts of lubricant EBS, 0.08 parts of lubricant calcium stearate, 0.15 parts of lubricant white oil 36 #Put it in a high-speed mixer for high-speed mixing for 2.8 minutes. The speed of the high-speed mixer is 230 rpm and the temperature is 27°C. The mixed mixture is fed into a twin-screw extruder for melt cross-linking extrusion, stranding, and pelletizing to finally obtain a cross-linked ethylene-alpha olefin copolymer. The temperature of the twin-screw extruder is 30°C, 40°C, 100°C, 105°C, 105°C, 108°C, 108°C, 110°C from the feeding section to the machine head, the length-to-diameter ratio of the twin-screw is 25, and the screw speed is 110 rpm.

[0095] (2) Preparation of ultra-low temperature resistant polypropylene composites

[0096] First, put 17 parts of the cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com