Treatment process applicable to industrial wastewater and application of industrial wastewater in preparation of bacterial manure

A technology for treating process and industrial sewage, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, application, etc., can solve the problems of human physical and mental health hazards, complex components of industrial sewage, microbial decomposition and utilization, etc., to achieve treatment The process is simple and feasible, avoiding secondary pollution and improving the effect of soil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A treatment process for industrial sewage, comprising the steps of:

[0032] Step 1): Mix the mixed bacterial solution, kaolin and wheat bran according to the weight ratio of 2:1:1, stir evenly, and then dry at low temperature, and control the water content at 5% after drying to obtain the composite bacterial agent; the mixed bacterial The solution is mixed with the following raw materials by volume: 6 parts of Micrococcus luteus, 5 parts of Bacillus colloidus, 4 parts of Paracoccus denitrificans, 3 parts of Rhodococcus, 3 parts of acidophilic Thiobacillus ferrooxidans, and Bacillus megaterium 2 parts of bacillus and 2 parts of bacillus cereus; the concentration of the above-mentioned raw material bacteria was controlled at 2×10 7 a / ml;

[0033] Step 2): discharge the industrial sewage into the sedimentation tank, let it stand for 12 hours, then adjust the pH to 7, and discharge it into the microbial reaction tank;

[0034] Step 3): Add compound bacterial agent to the...

Embodiment 2

[0038] A treatment process for industrial sewage, comprising the steps of:

[0039] Step 1) Preparation of compound bacterial agent: mix the mixed bacterial liquid, kaolin and wheat bran according to the weight ratio of 2:1:1, stir evenly, and then dry at low temperature. After drying, the water content is controlled at 5%. The bacterial liquid is mixed by the following volumes of raw material bacteria: 5 parts of Micrococcus luteus, 4 parts of Bacillus colloidus, 3 parts of Paracoccus denitrificans, 2 parts of Rhodococcus, 2 parts of acidophilic Thiobacillus ferrooxidans, giant 1 part of Bacillus and 1 part of Bacillus cereus; the concentration of the above-mentioned raw material bacteria is controlled at 5×10 7 a / ml;

[0040] The Micrococcus luteus is Micrococcus luteus (Micrococcus luteus.) ATCC 49732; (for example, Journal of Applied Ichthyology Volume 23, Issue 1, pages 80-86, February 2007);

[0041]The glial bacillus is Bacillus mucilaginosus Krassilnikov ATCC10012 (f...

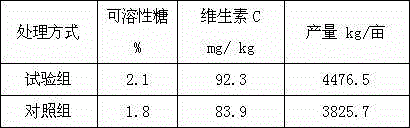

Embodiment 3

[0052] Lanshan District Industrial Sewage Treatment Plant, sampling and determination of COD, ammonia nitrogen, volatile phenols data; divided into two groups, embodiment 1 group, embodiment 2 group, each group of sewage is 1000L, COD before treatment is 5600mg / L, ammonia nitrogen is 431mg / L, volatile phenols 109mg / L; measure the COD, ammonia nitrogen, volatile phenols data of embodiment 1 and embodiment 2, see table 1:

[0053] Table 1

[0054] group COD average removal rate Ammonia nitrogen average removal rate Volatile phenols removal rate Example 1 89% 94% 91% Example 2 91% 95% 93%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com