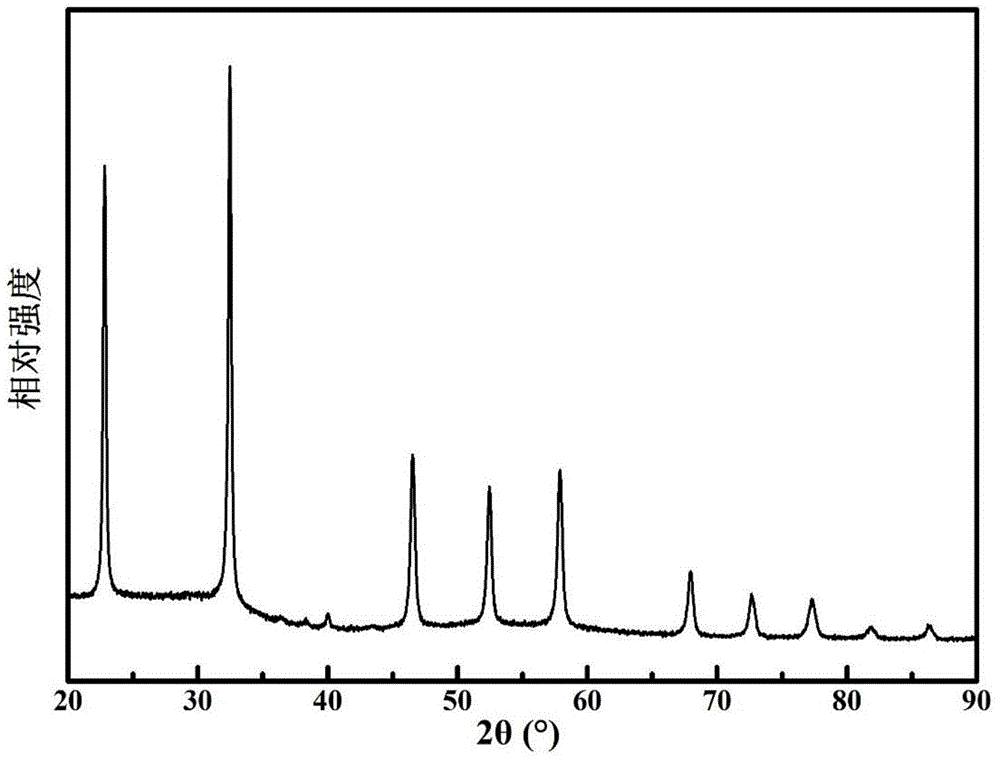

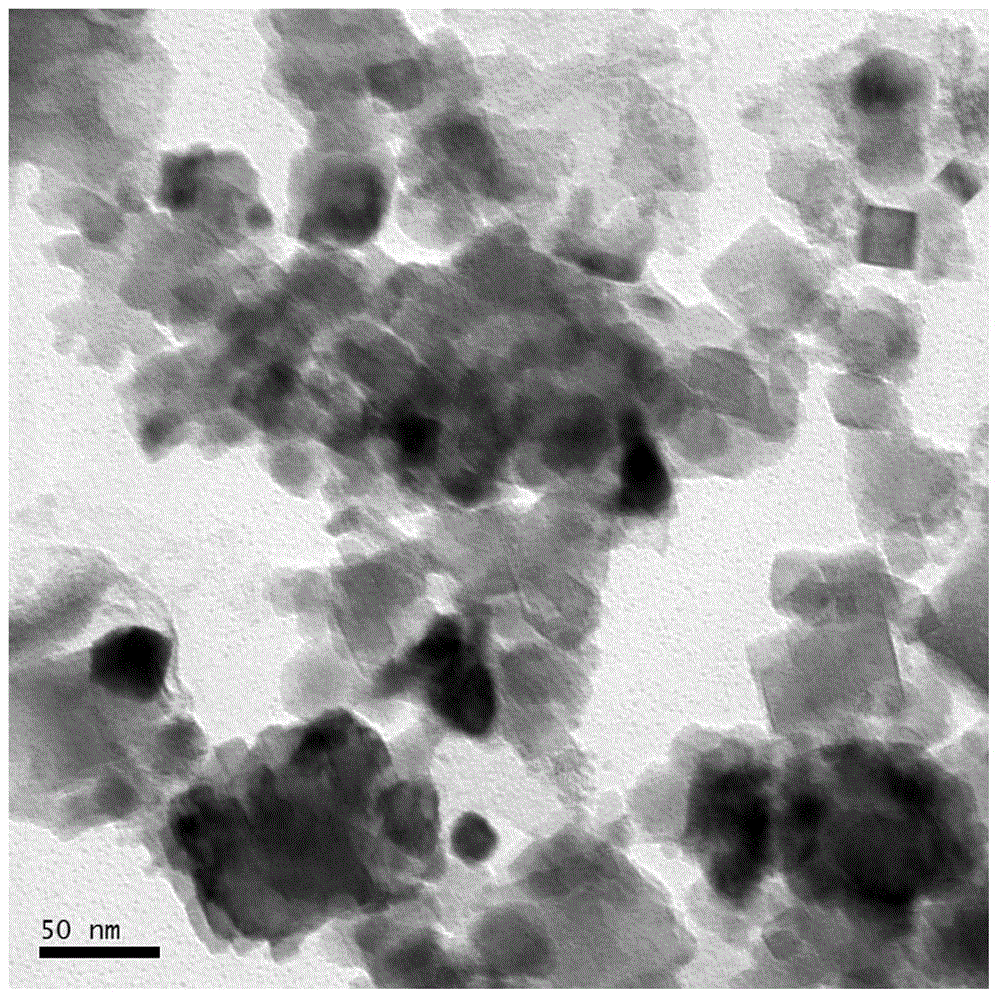

A kind of preparation method of high-purity cubic sodium niobate nanopowder

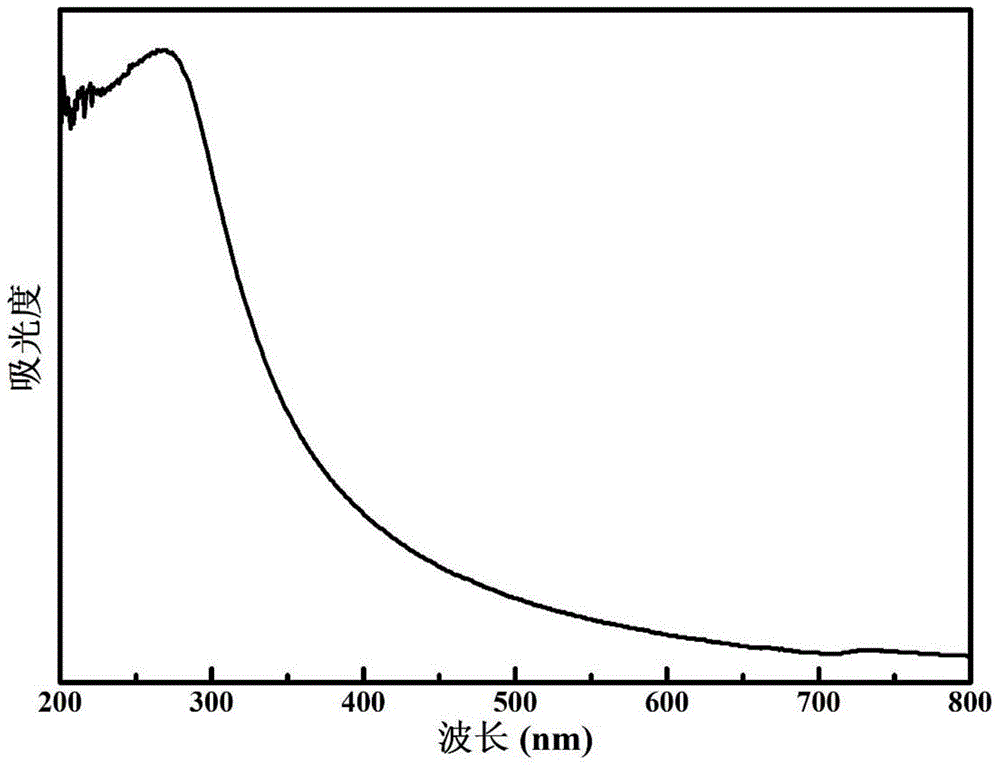

A technology of phase sodium niobate and nanopowder, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., and can solve the problems of complex preparation process of cubic phase sodium niobate nanostructure, unfavorable large-scale production, unfavorable application, etc. , to achieve the effects of economical toxicity, sensitive response to visible light, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing high-purity cubic phase sodium niobate nano powder, the steps are:

[0022] (1) Dissolve niobium oxalate and sodium chloride in 3 or 4 or 6 or 7 ml of deionized water according to the molar ratio of 0.06 or 0.11 or 0.13 or 0.15 or 0.18 or 0.20 or 0.24 or 0.25;

[0023] (2) Grind in an agate mortar for 30 or 35 or 40 or 45 or 50 minutes, and add 5 or 6 or 7 or 8 or 10 ml of absolute ethanol during the grinding process;

[0024] (3) Put the precursor obtained in step (2) in a vacuum drying oven at a vacuum degree of -50 or -60 or -70 or -80 or -90 or -100 kPa and a temperature of 60 or 65 or 70 or Drying at 76 or 80 or 85 or 90 degrees Celsius;

[0025] (4) Heat the dried precursor powder to 350 or 380 or 400 or 420 or 430 or 450 or 480 or 500 degrees Celsius in an energy-saving box-type electric furnace, keep it for 2 or 3 or 4 or 5 hours, and then cool naturally To 20 or 22 or 24 or 25 degrees Celsius;

[0026] (5) Centrifugally wash the powder obtained i...

Embodiment 2

[0033] A method for preparing high-purity cubic phase sodium niobate nano powder, the steps are:

[0034] (1) Dissolve niobium oxalate and sodium chloride in 2 or 3 or 4 milliliters of deionized water at a molar ratio of 0.08;

[0035] (2) Grind in an agate mortar for 38 minutes, and add 3 or 5 or 9 ml of absolute ethanol during the grinding process;

[0036] (3) Put the precursor obtained in step (2) in a vacuum drying oven at a vacuum degree of -50 or -55 or -62 or -68 or -74 or -78 or -86 or -92 or -100 kPa , Drying at a temperature of 60 or 66 or 72 or 78 or 84 or 90 degrees Celsius;

[0037] (4) Heat the dried precursor powder to 410 degrees Celsius in an energy-saving box-type electric furnace, keep it for 2 hours, and then naturally cool to 20-25 degrees Celsius;

[0038] (5) Centrifugally wash the powder obtained in step (4) with a mixed solution of deionized water and absolute ethanol for 3 times, the volume ratio of deionized water and absolute ethanol is 1:2, and the centrif...

Embodiment 3

[0044] A method for preparing high-purity cubic phase sodium niobate nano powder, the steps are:

[0045] (1) Dissolve niobium oxalate and sodium chloride in 3 or 4 or 5 milliliters of deionized water at a molar ratio of 0.07;

[0046] (2) Grind in an agate mortar for 36 minutes, and add 4 or 5 or 7 ml of absolute ethanol during the grinding process;

[0047] (3) Put the precursor obtained in step (2) in a vacuum drying oven at a vacuum degree of -50 or -61 or -71 or -81 or -90 or -100 kPa and a temperature of 60 or 68 or 76 or Drying at 85 or 90 degrees Celsius;

[0048] (4) Heat the dried precursor powder to a temperature of 440 degrees Celsius in an energy-saving box-type electric furnace, keep it for 2 hours, and then naturally cool it to 20-25 degrees Celsius;

[0049] (5) Centrifugally wash the powder obtained in step (4) with a mixed solution of deionized water and absolute ethanol for 3 times, the volume ratio of deionized water and absolute ethanol is 1:3, and the centrifugal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com