Method for improving binding strength of medical bio-coating on surface of medical magnesium alloy

A technology of biological coating and bonding strength, applied in the field of medical biology, can solve the problems of poor bonding strength between hydroxyapatite coating and implant, complex manufacturing process, uneven coating distribution, etc., to avoid surface crack defects, High controllability and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] Such as Figure 1-3 shown.

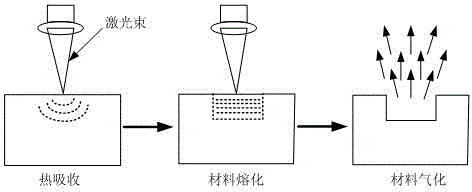

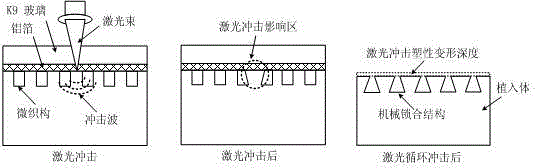

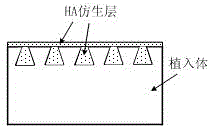

[0032] A method to improve the bonding strength of medical bio-coatings on the surface of medical magnesium alloys. Firstly, a micro-groove array is formed through the laser thermal effect on the surface of the substrate, and then the laser is used to shock the surface of the material to form a contracted microstructure. Finally, bionic growth of medical (HA) in simulated body fluid ) coating, using the shrinkage microstructure to make the HA coating form a locked structure, which improves the bonding strength between the coating and the substrate, coating performance and uniformity, such as Figure 1~3 . The implementation process is as follows:

[0033] 1) The experimental material is biomedical AZ31B magnesium alloy. First, use metallographic sandpaper 280#, 320#, 600#, 800#, 1200# to polish the AZ31B magnesium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com