Preparation method of fe3o4/go magnetic composite material

A technology of magnetic composite materials and magnetic microspheres, which can be used in the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

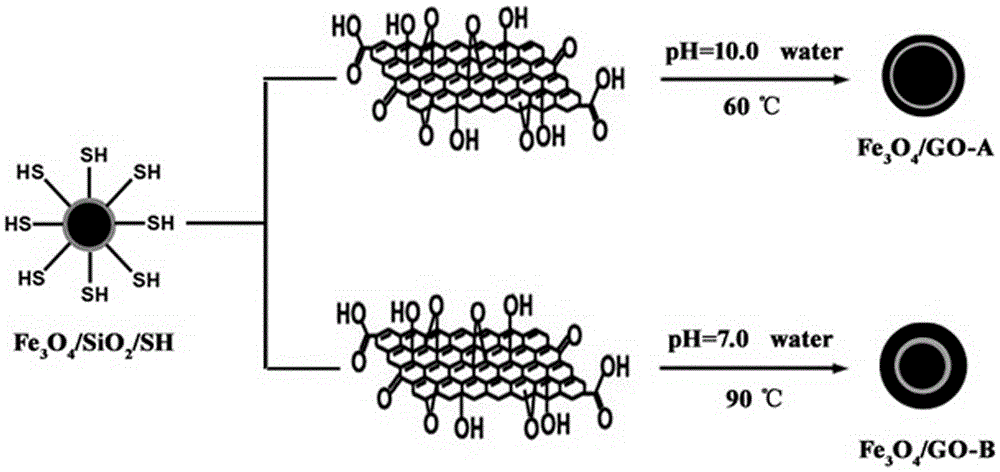

[0044] Preparation of Fe 3 o 4 / GO-A

[0045] 20mgFe 3 o 4 / SiO 2 / SH and 10 mg GO were added to 60 mL of an aqueous solution with a pH of 10.0, ultrasonically dispersed for 5 min, then mechanically stirred at 60 °C for 6 h, then the reaction was stopped and the Fe 3 o 4 / GO was separated from the supernatant, washed 3 times with water and dried in vacuum to obtain a Fe 3 o 4 / GO magnetic composite material Fe 3 o 4 / GO-A.

[0046] Wherein the external magnet is to place a magnet outside the bottom of the beaker; the magnetic microspheres modified by thiol (Fe 3 o 4 / SiO 2 / SH) particle size is about 200nm.

Embodiment 2

[0048] Preparation of Fe 3 o 4 / GO-B

[0049] 20mgFe 3 o 4 / SiO 2 / SH and 10 mg GO were added to 60 mL of an aqueous solution with a pH of 7.0, ultrasonically dispersed for 5 min, then mechanically stirred at 90 °C for 6 h, then the reaction was stopped and the Fe 3 o 4 / GO was separated from the supernatant, washed 3 times with water and dried in vacuum to obtain another Fe 3 o 4 / GO magnetic composite material Fe 3 o 4 / GO-B.

[0050] Wherein the external magnet is to place a magnet outside the bottom of the beaker; the magnetic microspheres modified by thiol (Fe 3 o 4 / SiO 2 / SH) particle size is about 200nm.

[0051] The synthetic reaction schematic diagram of above-mentioned embodiment 1 and embodiment 2 sees figure 1 .

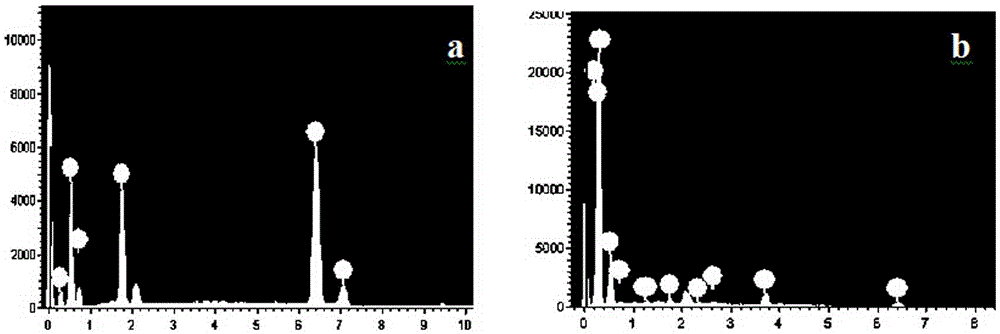

[0052] To the Fe obtained in above-mentioned embodiment 1 and embodiment 2 3 o 4 / GO magnetic composites were analyzed and tested, and their characterizations are as follows.

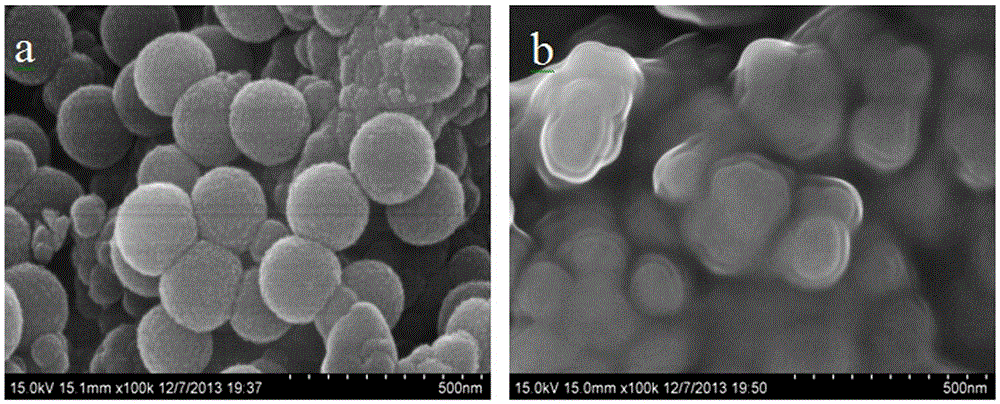

[0053] SEM analysis

[0054] Fe 3 o 4 / GO-A and Fe 3 o ...

Embodiment 3

[0067] Magnetic solid phase extraction of aromatic amines

[0068] First, weigh 10 mg Fe 3 o 4 / GO was added to a 150mL water sample with a pH of 5.0, and the aromatic amine and Fe 3 o 4 / GO binding and capture to the solid surface. In order to capture the aromatic amine more completely, the mixture was first ultrasonicated for 2 min, and then placed in a water bath at 20°C for 15 min to equilibrate. Then a magnet is added to move the Fe 3 o 4 The / GO-arylamine complex was separated from the water sample, and the aromatic amine was desorbed with 2 mL of acetonitrile (1% NaOH).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com