Processing method of integrated piezoresistive accelerometer and pressure meter which are based on prefabricated cavity SOI (silicon on insulator) substrate

A technology of accelerometers and processing methods, applied in the direction of acceleration measurement using inertial force, technology for producing decorative surface effects, microstructure devices composed of deformable elements, etc., which can solve the problem of device sensitivity reduction, lateral piezoresistance Problems such as small coefficient, difficult corrosion progress detection, etc., achieve the effect of large piezoresistive coefficient, accurate thickness and size, and save the vacuum packaging step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

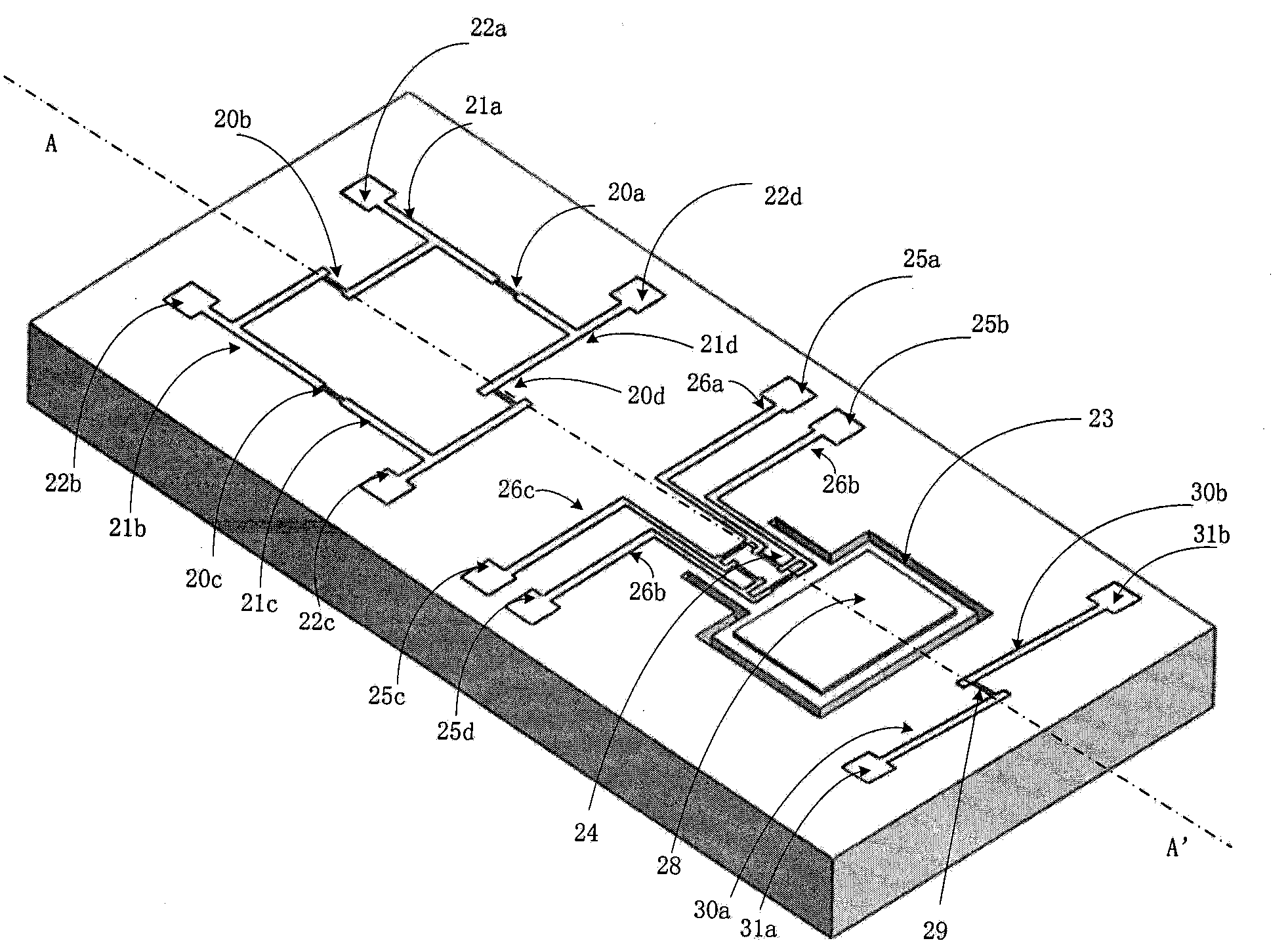

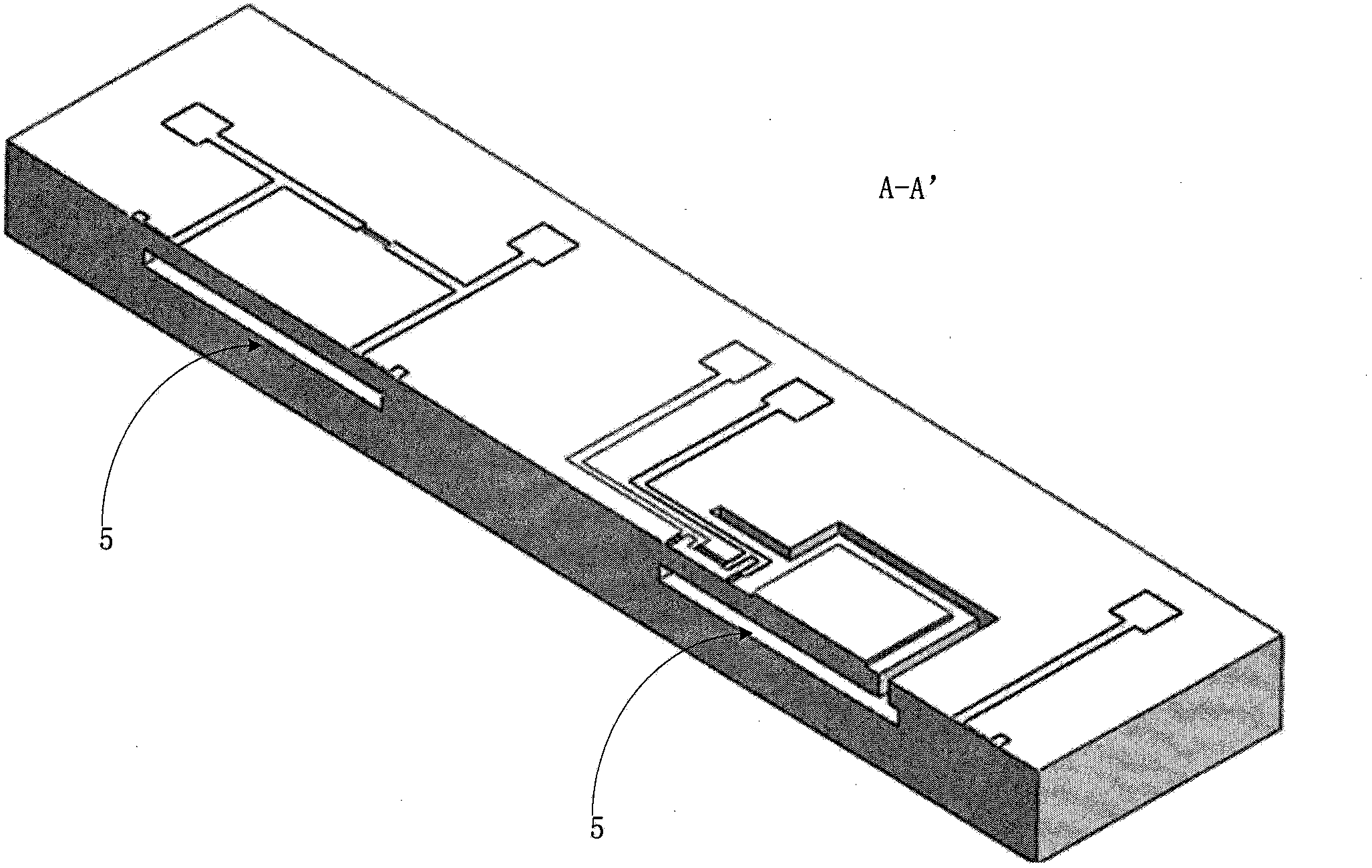

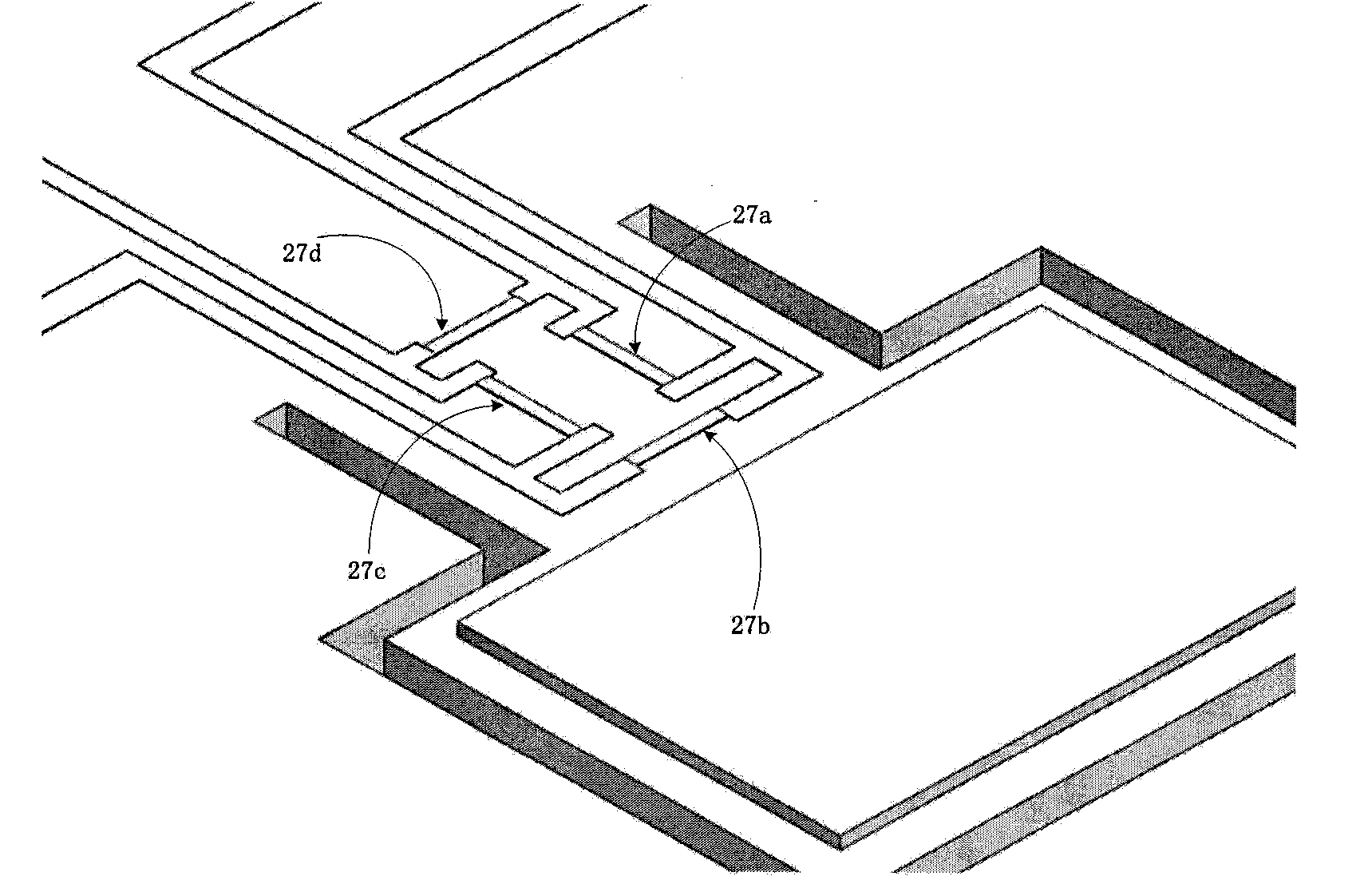

[0038] Figure 1A ~ Figure 1C It is a structural schematic diagram of the integrated piezoresistive accelerometer and pressure gauge based on the prefabricated cavity SOI substrate according to the present invention. Figure 1A The structural representation of the integrated piezoresistive accelerometer and pressure gauge based on the prefabricated cavity SOI substrate processed for the present invention, Figure 1B for Figure 1A A-A' sectional view of an integrated piezoresistive accelerometer and pressure gauge based on a prefabricated cavity SOI substrate as described in, Figure 1C for Figure 1A An enlarged view of the accelerometer cantilever portion of the integrated piezoresistive accelerometer and pressure ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com