Solid nicotine-comprising dosage form with reduced organoleptic disturbance

A nicotine and dosage form technology, which is applied in the directions of non-active ingredient medical preparations, medical preparations containing active ingredients, and pill delivery, etc., can solve the problems of lack of nicotine, undisclosed, and lack of buffers in film coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0078] Manufacturing method

[0079]The composition of the batches for the tablet cores is given in Table A1 below. The material is sieved using a vibrating sieve with a mesh size of 1 mm, and thereafter blended for 10 to 30 minutes according to methods known in the art, eg, using a double cone mixer. The blended material is then compressed into tablets by means of direct compression. Powder compression can be performed, for example, using a rotary tablet press with 15mm round concave punches. The tablets are compressed to a sufficient hardness to allow an acceptable coating process and to achieve the desired in vivo dissolution time.

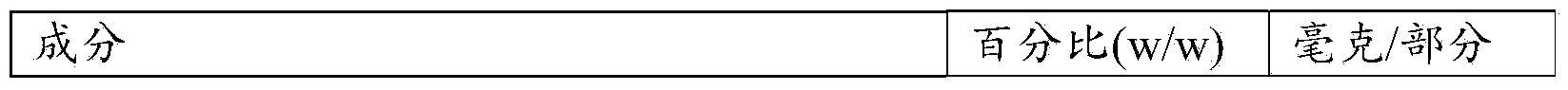

[0080] Table 1A: Components of Tablet Cores .

[0081] Element

percentage (w / w)

mg / part

Nicotine Resin Complex (20% Nicotine)

1.5

15*

89.0

890

5.75

57.5

0.25

2.5

0.5

5

mint flavoring

...

example 2

[0107] According to the manufacture method of the tablet of example 1

[0108] Table 2A: Components of Tablet Cores .

[0109] Element

percentage (w / w)

mg / part

Nicotine Resin Complex (20% Nicotine)*

1.67

10.0

93.56

561.36

0.5

3.0

mint flavoring

1.67

10.02

0.1

0.6

2

12.0

Silica (colloid)

0.5

3.0

total

100

600

[0110] *Equivalent to a 2.0mg dose of nicotine base. If a nicotine resin complex is used with other levels of nicotine loading such as 15%, the amount of polyol is adjusted accordingly.

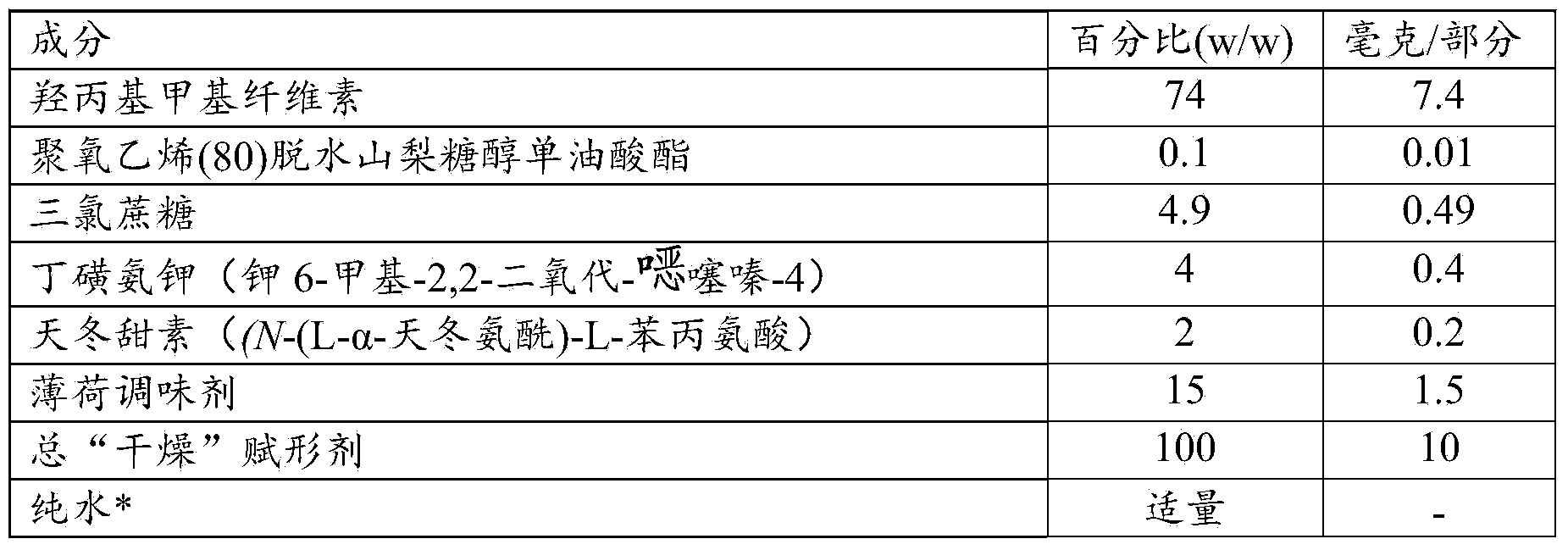

[0111] Film coating of the tablets produced in 2A can be performed using, for example, a standard modern pan coater equipped with an air atomized spray nozzle dispensing the film coating fluid and a perforated drum of appropriate size. Membrane solutions were prepared by adding hydroxypr...

example 3

[0118] Following Example 2, a total tablet core weight of 650 mg was used, with oval 14.5 mm punches, but without sodium bicarbonate and / or sodium carbonate (which was compensated by the amount of mannitol). Additionally, the components of the film coating are provided in Table 3A.

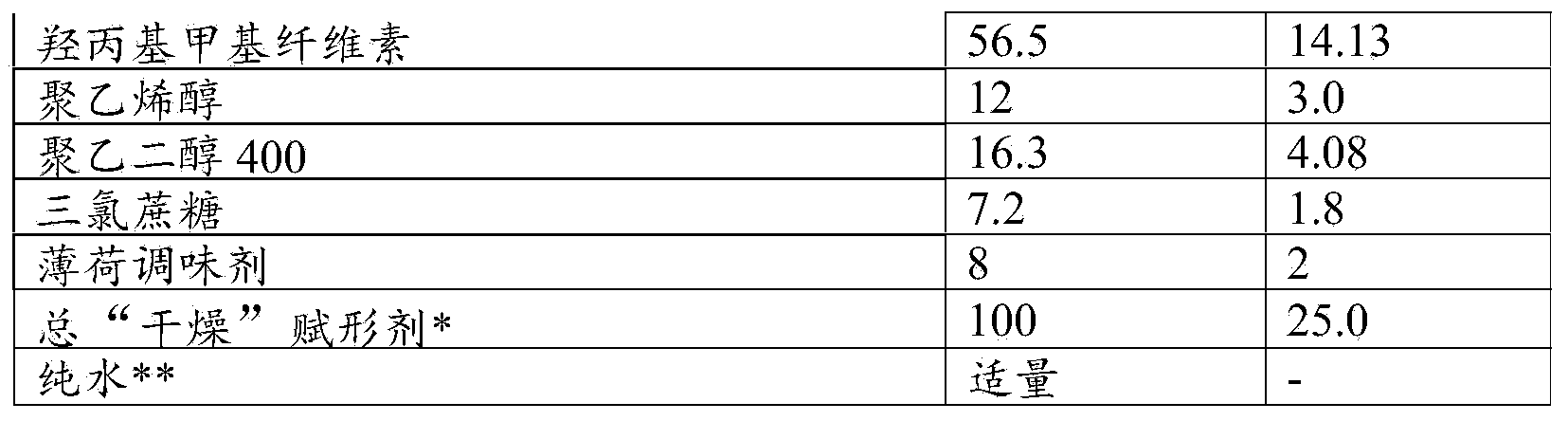

[0119] Table 2B: Components of the film coating .

[0120]

[0121]

[0122] *Total excipients except purified water

[0123] **Add the appropriate amount of pure water to achieve a dry content suitable for the coating process parameter settings to be applied, for example the dry content can be 16% w / w.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com