Preparation method of multilevel-structured hollow nano-sphere of negative electrode material of high-performance lithium ion secondary battery

A technology for secondary batteries and negative electrode materials, which is applied in the field of preparation of hollow nanospheres with multi-level structures, achieving the effects of low production cost, good rate performance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

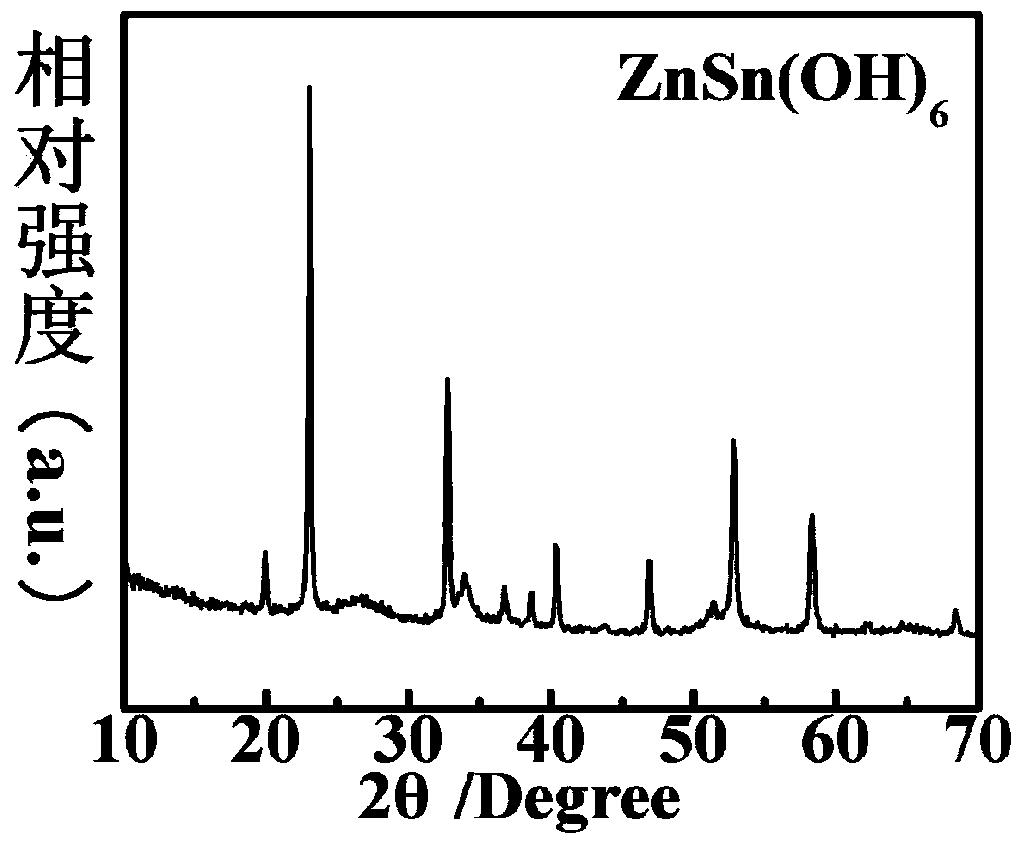

[0045] Hierarchical Structure Nano ZnSn(OH) 6 Preparation of hollow spheres

[0046] 2m mol of Zn(CHCOO) 2 2H 2 O. 0.75g PAA was dissolved in 25mL of distilled water, stirred for 30min; 1.9mmol of Na 2 SnO3 4H 2 O was dissolved in 10mL of distilled water to make a solution, added dropwise to the above mixed solution, and continued to stir for 30min; to the above white turbid solution, 6mL NH 3 ·H 2 O. After stirring for 30 min, the above mixture was transferred to a 60 mL reaction kettle and maintained at 180°C for 24 h. After the reaction kettle is cooled down to room temperature, the obtained white product is centrifuged several times through absolute ethanol and distilled water. After the product is collected, it is dried under vacuum at 60°C. The obtained white product is a hierarchical structure nano-hydroxytin composed of nanorods Zinc acid hollow spheres. The XRD pattern, SEM photo and TEM image of the hierarchical structure nano-zinc hydroxystannate hollow spher...

Embodiment 2

[0048] Hierarchical structure nano Zn 2 SnO 4 Preparation of hollow spheres

[0049] Take an appropriate amount of the obtained zinc hydroxystannate compound, spread it evenly on a porcelain boat, place it in a crucible furnace, and calcinate at 600°C for 6h, with a heating rate of 5°C / min. The obtained product is a hollow nanometer zinc stannate hollow sphere. The XRD patterns, SEM photos and TEM images of the nano-zinc stannate hollow spheres with hierarchical structure figure 2 and Figure 4 shown.

Embodiment 3

[0051] Product performance test

[0052] Two products, the zinc stannate hollow spheres obtained in Example 1 and the zinc stannate hollow spheres obtained in Example 2, are used as negative electrode materials for lithium-ion secondary batteries, and the electrodes are prepared by a coating method. Material: Acetylene black: CMC=60:30:10 mixed in a ratio of 60:30:10, using distilled water as a solvent to make a negative electrode slurry, coated on a 12mm copper foil, fully dried and pressed to obtain a negative electrode sheet. Lithium sheet is used for battery positive sheet. In a glove box protected by inert gas, a 2320-type button cell was assembled with 1mol / L LiPF6 / EC / DMC / DEC (1:1:1) as the electrolyte and Celgerd2300 as the separator. Test instruments: charge and discharge instrument (Land); JEM-1011 transmission electron microscope, Bruker D8-X-ray diffractometer.

[0053] Test Results

[0054] Carry out the battery charge and discharge performance test on the blue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com