Light-emitting diode (LED) epitaxial wafer growing on Si patterned substrate and preparation process of LED epitaxial wafer

A technology of LED epitaxial wafers and graphic substrates, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting the growth quality of GaN, epitaxial wafer cracks, and reduce LED luminous efficiency, etc., to avoid light absorption difficulties , Promote lateral epitaxial growth, and improve crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

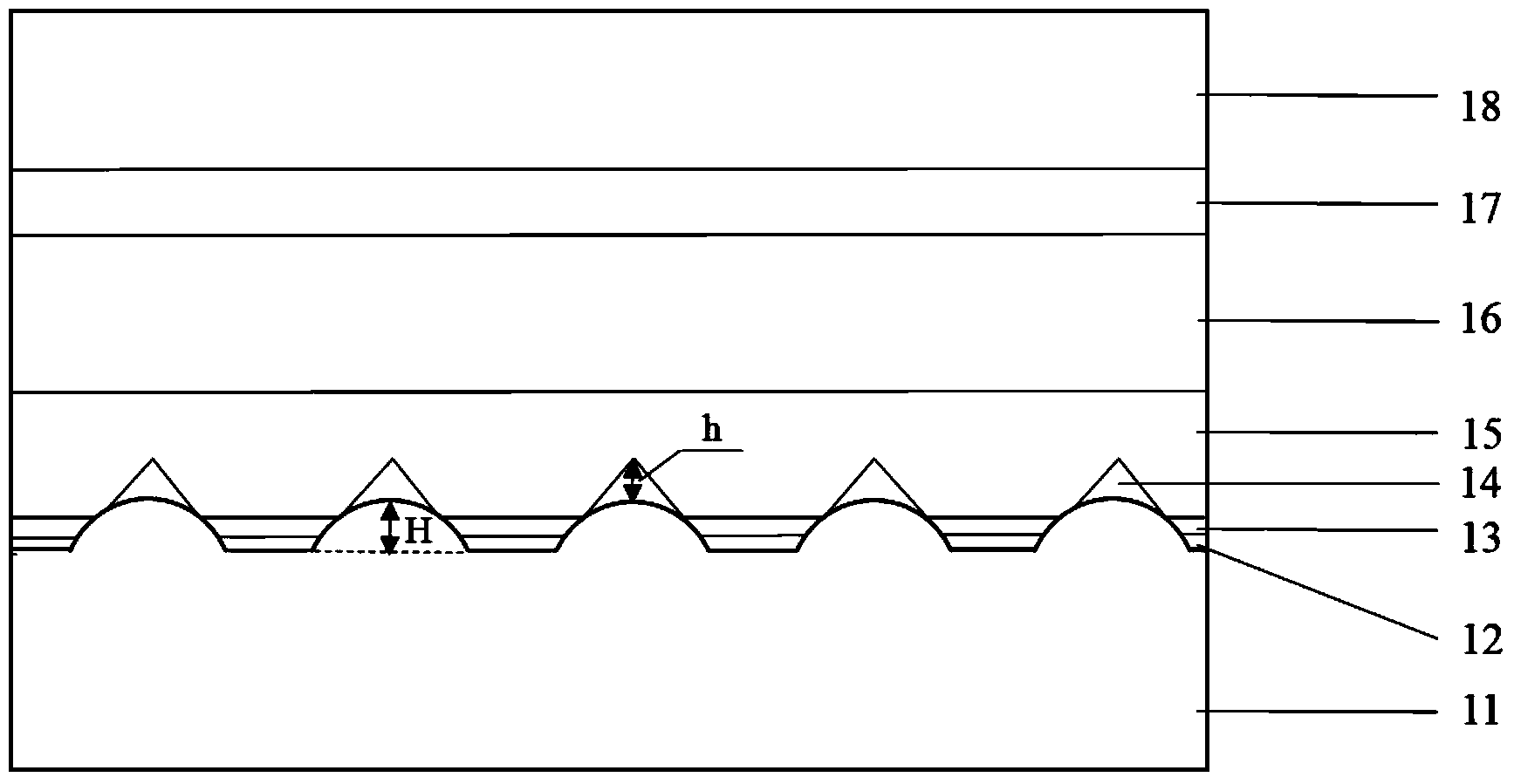

[0044] Please refer to Figure 1-Figure 3 , a kind of LED epitaxial wafer grown on the Si pattern substrate of the present invention, it comprises Si pattern substrate 11, the crystal orientation of described Si pattern substrate 11 is (111), is distributed with several identical shapes Pattern bump 11-1; AlN buffer layer 12, AlGaN step buffer layer 13, u-GaN layer 15, n-GaN layer 16, InGaN / GaN quantum well layer 17 are sequentially grown on the Si pattern substrate 11 and a p-GaN layer 18; a cavity 14 is formed on the top of each patterned protrusion 11-1.

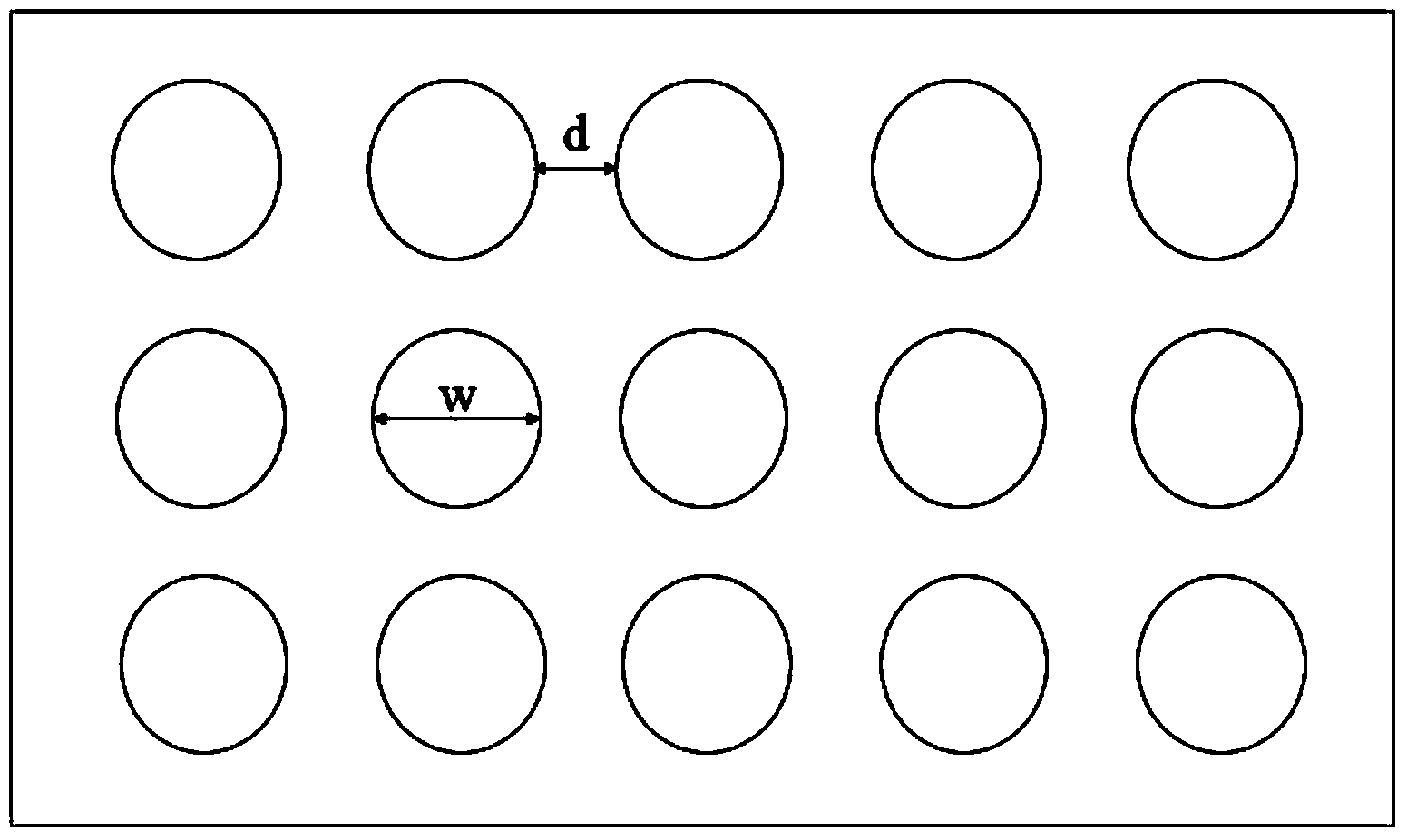

[0045] The graphic protrusions 11-1 are in the shape of a hemisphere, the height H of the hemisphere is 1 μm, the side distance d is 1 μm, and the bottom width w is 1.5 μm; the arrangement is rectangular.

[0046] The above-mentioned LED epitaxial wafer grown on the Si pattern substrate is obtained by the following method:

[0047] (1) Selection of the substrate and its crystal orientation: a Si pattern substrate is use...

Embodiment 2

[0058] The characteristics of this embodiment are:

[0059] The LED epitaxial wafer grown on the Si pattern substrate is obtained by the following method:

[0060] (1) Selection of the substrate and its crystal orientation: a Si pattern substrate is used, and the (111) plane is selected.

[0061] (2) A 20nm-thick AlN buffer layer was grown by metal-organic chemical vapor deposition. The process conditions were: substrate temperature 960°C, reaction chamber pressure 100Torr, V / III ratio 3500, growth rate 0.3μm / h.

[0062] (3) AlGaN stepping buffer layer was grown by metal-organic chemical vapor deposition process. 3 The flow rate is 15slm, the TMAl flow rate is 250 sccm, the TMGa flow rate is 8 sccm, the growth rate is 0.2 μm / h, and the first AlGaN layer is grown with a thickness of 110 nm, and the Al doping amount is 80%; the TMGa flow rate is 25 sccm, and the growth rate is 0.4 μm / h, grow the second AlGaN layer with a thickness of 160nm, and the doping amount of Al is 60%; ...

Embodiment 3

[0071] This embodiment is modified on the basis of Embodiment 1, the difference is:

[0072] Please refer to Figure 5 , a plurality of cones with the same shape are arranged on the Si pattern substrate of the present invention, the height H of the cones is 1 μm, the side distance d is 1 μm, and the bottom width w is 1.5 μm; the arrangement is hexagonal.

[0073] Before growing the AlN buffer layer, the substrate is sequentially cleaned and annealed. The specific method is as follows:

[0074] Surface cleaning treatment: ultrasonically clean the Si pattern substrate in acetone solution first, then ultrasonically clean in deionized water; then ultrasonically clean in isopropanone solution; then ultrasonically clean in hydrofluoric acid solution, and then Soak in deionized water; then soak the Si pattern substrate in a mixed solution of sulfuric acid and hydrogen peroxide; finally soak the Si pattern substrate in hydrofluoric acid, rinse with deionized water, and blow dry with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com