Preparing method for high-purity sanshoamides

A high-purity technology of pepperianin, which is applied in the field of preparation of high-purity pepperianin, can solve the problems of high purity requirements of peppery oleoresin, lack of purification research on flavor substances, and unknown raw material composition requirements, etc., to achieve reduction in process Difficulty and cumbersomeness of operation technology, reduction of technical difficulty of process operation, and effect of reducing the amount of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

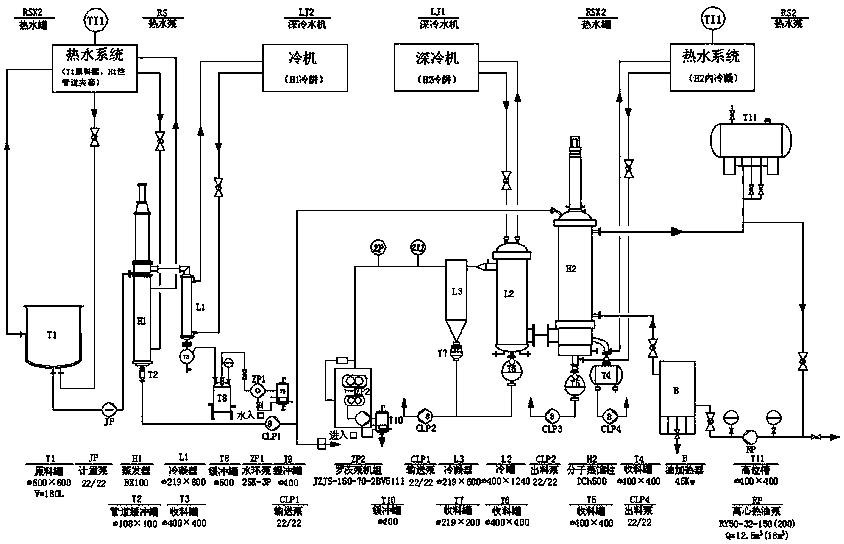

Image

Examples

preparation example Construction

[0023] The preparation method of high-purity xanthanin of the present invention is as follows:

[0024] ① Raw material pretreatment: use the Zanthoxylum oleoresin extracted by supercritical as raw material, heat until there are no insoluble solid particles, the heating temperature is 60-70°C, and the heating time is 10-15min; the Zanthoxylum oleoresin component includes Zanthoxylum aromatic oil , linalool, limonene, pepper amide substances;

[0025] ② Evaporation: Zanthoxylum oleoresin enters the evaporator H1 at a feed rate of 80-100ml / h, and distributes it continuously and evenly on the heating surface through the feed liquid distributor, and then the film wiper scrapes the feed liquid into a liquid film , the temperature of the heating surface is 80-95°C, the frequency of the wiper is 50HZ, the thickness of the liquid film is 0.01-0.02cm, and then the light component and the heavy component are separated under the vacuum degree of 40-50Pa;

[0026] ③Molecular distillation:...

Embodiment 1

[0053] The preparation method of high-purity xanthanin of the present invention is as follows:

[0054] ① Raw material pretreatment: use the Zanthoxylum bungeanum oleoresin extracted by supercritical as raw material, heat until there are no insoluble solid particles, the heating temperature is 60°C, and the heating time is 15 minutes; the supercritical extraction uses red Zanthoxylum bungeanum as raw material, during the extraction process The extraction pressure is 5MPa, the extraction temperature is 30°C, and the booster pump frequency is 15HZ; the Zanthoxylum oleoresin components include Zanthoxylum aromatic oil, linalool, limonene, and Zanthoxylum amide substances;

[0055] ② Evaporation: Zanthoxylum bungeanum oleoresin enters the evaporator at a feed rate of 80ml / h, and is continuously and evenly distributed on the heating surface by the feed liquid distributor, and then the film wiper scrapes the feed liquid into a liquid film, and the heating surface The temperature is ...

Embodiment 2

[0059] The preparation method of high-purity xanthanin of the present invention is as follows:

[0060] ① Raw material pretreatment: use the Zanthoxylum bungeanum oleoresin extracted by supercritical as raw material, heat until there are no insoluble solid particles, the heating temperature is 65°C, and the heating time is 12 minutes; the supercritical extraction uses red Zanthoxylum bungeanum as raw material, during the extraction process The extraction pressure is 5.8MPa, the extraction temperature is 25°C, and the booster pump frequency is 15HZ; the Zanthoxylum bungeanum oleoresin components include Zanthoxylum bungeanum aromatic oil, linalool, limonene, and Zanthoxylum amide;

[0061] ②Evaporation: Zanthoxylum bungeanum oleoresin enters the evaporator H1 at a feed rate of 90ml / h, and is continuously and evenly distributed on the heating surface by the feed liquid distributor, and then the film wiper scrapes the feed liquid into a liquid film, and heats The surface temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com