Aluminum fins

A fin and aluminum plate technology, which is applied in the field of aluminum fin materials for heat exchangers, can solve the problems of reduced hydrophilicity, easy blockage of fins, and maintenance of hydrophilicity on the surface of fins, achieving the effect of improved stamping processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0032]

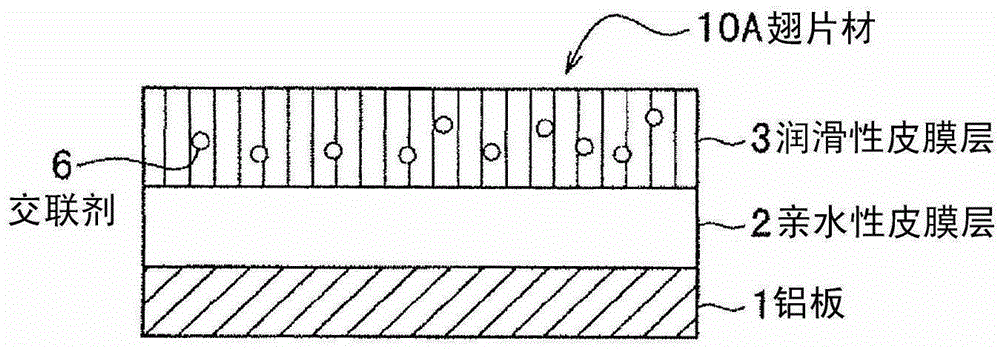

[0033] Such as figure 1 As shown, the aluminum fin material (hereinafter referred to as the fin material) 10A of the present invention includes in order: an aluminum plate or an aluminum alloy plate (hereinafter referred to as the aluminum plate) 1 , and a hydrophilic film layer 2 formed on the surface of the aluminum plate 1 and a lubricating film layer3. In addition, the lubricating film layer 3 includes a resin composition containing a lubricating resin and a crosslinking agent 6, and the ratio of the solid content of the crosslinking agent 6 to the total solid content of the lubricating resin and the crosslinking agent 6 is 0.2 to 70%. % by mass, the hydrophilic film layer 2 contains a resin composition containing a polymer having a carboxyl group or the like. Each configuration will be described below.

[0034] (aluminum plate)

[0035] The aluminum plate 1 used in the present invention is a plate material made of aluminum or an aluminum alloy. Such aluminu...

no. 2 Embodiment approach

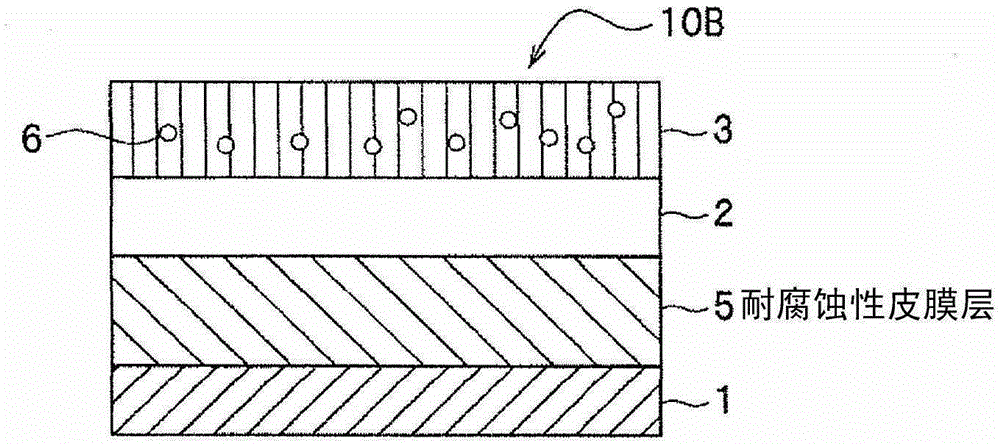

[0050] Such as figure 2 As shown, the fin material 10B preferably further includes a corrosion-resistant coating layer 5 containing a resin composition (corrosion-resistant resin composition) containing a corrosion-resistant resin between the aluminum plate 1 and the hydrophilic coating layer 2 .

[0051] (corrosion-resistant film layer)

[0052] The corrosion-resistant coating layer 5 improves the corrosion resistance of the fin material 10B, and also improves the adhesion of the hydrophilic coating layer 2 . In addition, since the corrosion-resistant film layer 5 is hydrophobic, it is possible to suppress the generation of unpleasant smell due to sub-film corrosion (corrosion of the aluminum plate 1 ) caused by water penetrating into the aluminum plate 1 .

[0053] The corrosion-resistant resin constituting the corrosion-resistant film layer 5 contains one or more types selected from polyester-based resins, polyolefin-based resins, epoxy-based resins, acrylic resins, and p...

no. 3 Embodiment approach

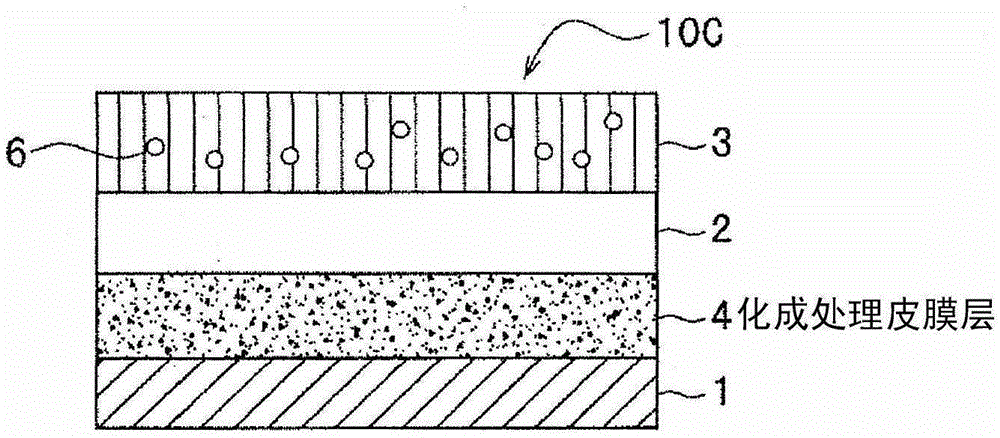

[0057] Such as image 3 As shown, the fin material 10C preferably includes the chemical conversion treatment film layer 4 between the aluminum plate 1 and the hydrophilic film layer 2 .

[0058] (Chemical treatment film layer)

[0059] The presence of the chemical conversion treatment film layer 4 improves the corrosion resistance of the fin material 10C, and further improves the adhesion of the hydrophilic film layer 2 to the aluminum plate 1 . Therefore, the durability of the heat exchanger can be improved. In addition, the chemical conversion treatment film layer 4 is formed by subjecting the surface of the aluminum plate 1 to a chemical conversion treatment before forming the hydrophilic film layer 2 .

[0060] The chemical conversion treatment film layer 4 is preferably formed by performing an inorganic oxide treatment such as phosphoric acid chromate treatment or coating type zirconium treatment, or a known chemical conversion treatment such as organic-inorganic compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com