A nanometer-precision electrochemical etching processing method

A processing method and electrochemical technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of high cost, increased etching process steps, and high manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

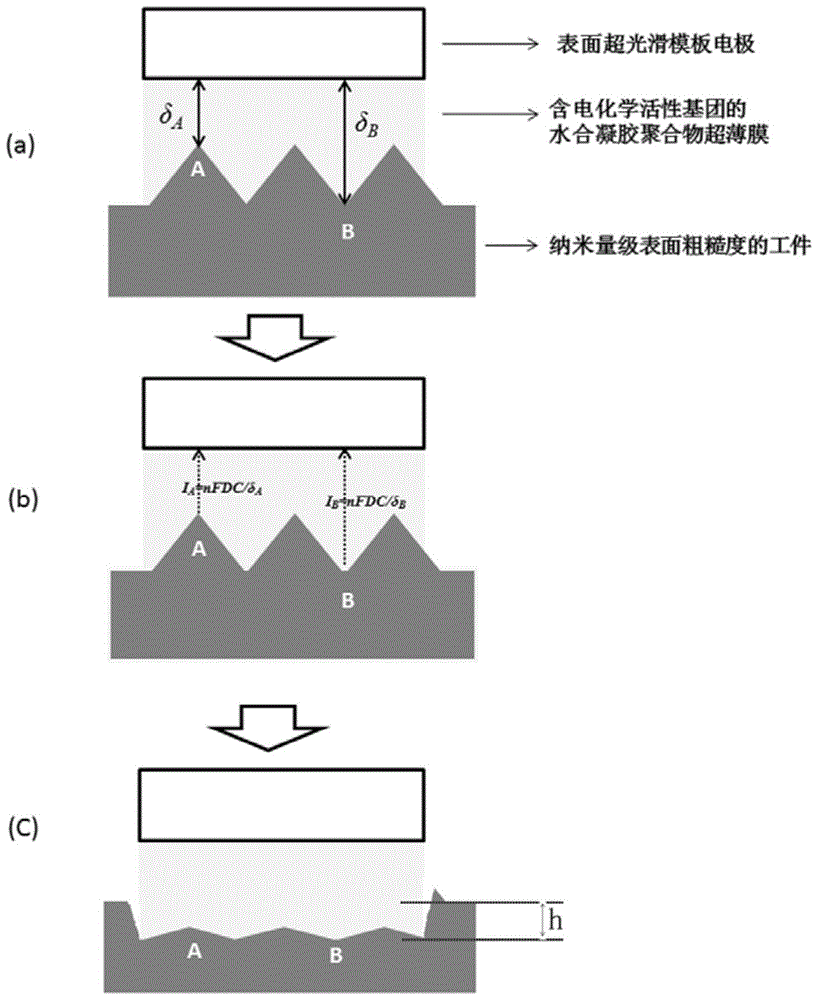

[0041] figure 1 A schematic diagram of the device composition of the embodiment of the electrochemical etching processing method of the present invention is given. The template electrode 4 stands vertically on the surface of the workpiece 5 naturally, and the surface of the template electrode 4 and the workpiece 5 is separated by a hydrated gel polymer ultra-thin film 6 containing electrochemically active groups; The line 9 is connected to the electrochemical workstation 1 to become an electrochemical working electrode. The electrochemical system also includes an auxiliary electrode 2, a reference electrode 3, a working solution 7, and a container 8. The container 8 is placed on the active vibration isolation workbench 10.

[0042] Electrochemical etching processing method of the present invention, its working principle is:

[0043] (1) Use a soft hydrated gel polymer ultra-thin film containing electrochemically active groups to separate the template electrode and the workpie...

Embodiment 2

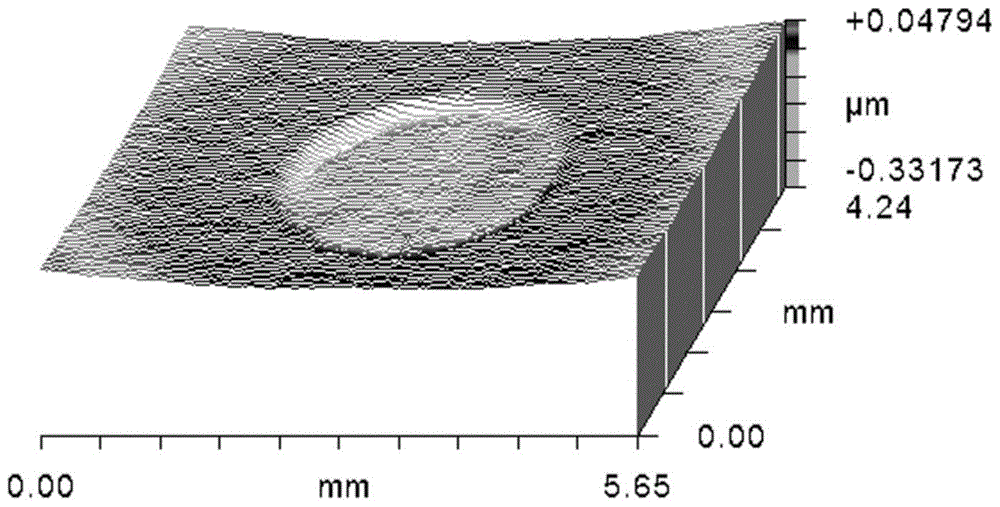

[0052] In Example 2, the template electrode 4 is an ultra-smooth glassy carbon disc electrode with a diameter of 3 mm, the auxiliary electrode 2 is a platinum electrode, the reference electrode 3 is a saturated calomel electrode, and the workpiece 5 is an oxygen-free metal copper material. Etching process contains 0.1mol / dm at pH 3.0 3 Acetic acid and 0.2mol / dm 3 Carry out in the working solution 7 of sodium sulfate, temperature is kept on 25 ℃, and concrete implementation process is as follows:

[0053] (1) First remove the oxygen containing 0.0044mol / dm 3 [Ru(bpy) 2 (vp) 2 ](PF6 ) 2 and 0.1mol / dm 3 Bu 4 NPF 6 (bpy: bipyridine; vp: vinylpyridine; PF 6 - : hexafluorophosphate ion; Bu 4 N + : Tetrabutyl quaternary ammonium cation), with metal platinum as the auxiliary electrode, metal silver wire as the reference electrode, using a speed of 0.2V / s to scan 100 cycles in the potential interval from 0 to -2.0V, on the template electrode 4 Electrochemically polymerize a...

Embodiment 3

[0059] In Example 3, the template electrode 4 is a platinum metal wire electrode with a diameter of 50 μm, the auxiliary electrode 2 is a platinum electrode, the reference electrode 3 is a saturated calomel electrode, and the workpiece 5 is a gallium arsenide material. Etching process contains 0.1mol / dm at pH 3.0 3 Acetic acid and 0.2mol / dm 3 Carry out in the working solution 7 of sodium sulfate, temperature is kept on 25 ℃, and concrete implementation process is as follows:

[0060] (1) First remove the oxygen containing 0.0044mol / dm 3 [Ru(bpy) 2 (vp) 2 ](PF 6 ) 2 and 0.1mol / dm 3 Bu 4 NPF 6 In the acetonitrile solvent or dimethyl sulfoxide solvent, the metal platinum is used as the auxiliary electrode, the metal silver wire is used as the reference electrode, and the scanning speed is 0.2V / s, and the potential range of 0 to -2.0V is scanned for 200 cycles. Electrochemically polymerize a layer of hydrated gel polymer ultra-thin film 6 containing bipyridyl ruthenium gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com