Solid electrolyte, preparation method and application thereof, and lithium battery using solid electrolyte

A technology of solid electrolyte and lithium salt, applied in the direction of non-aqueous electrolyte batteries, solid electrolytes, lithium batteries, etc., can solve the problems of reduced mechanical properties, poor electrical conductivity, poor mechanical properties, etc., and achieve improved electrical conductivity, good mechanical strength, and processing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

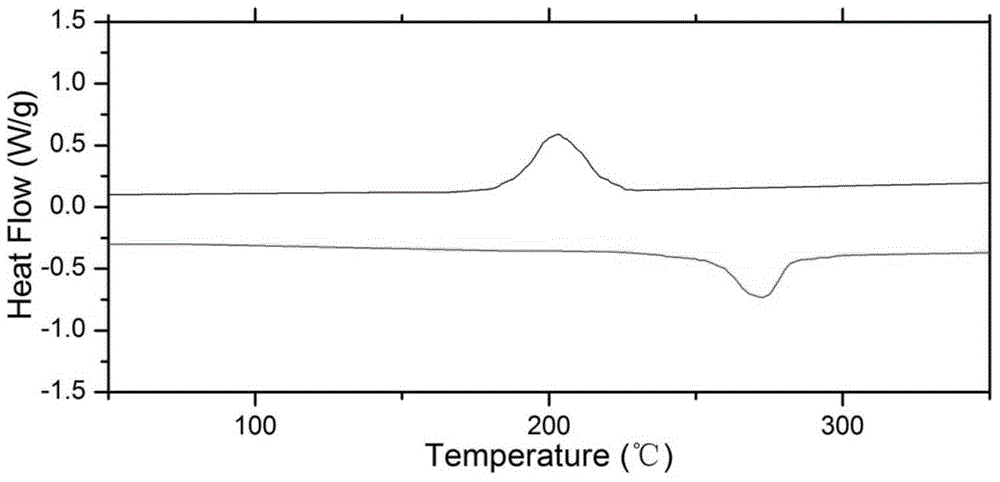

Image

Examples

Embodiment 1

[0049] A choose polyphenylene ether (PPO), purchased from SABIC company NORYL TM SA120FIN in the PPO RESIN series.

[0050] B select lithium benzoate (C 6 h 5 COOLi), purchased from Sigma Aldrich.

[0051] C selection fatty acid monoethanolamide was purchased from PHOENIX CHEMICAL, INC.

[0052] Preparation process:

[0053] Put 13.1 kilograms of raw material A into a vacuum drier, and dry it for 24 hours at 100 degrees Celsius. Put 4.4 kg of raw material B into a planetary ball mill, and grind it into particles with a diameter less than 1 micron. Mix the dried A raw material, B material and 0.5 kg of C material in a high-speed mixer for 15 minutes, and the mixing process may heat up to 120 degrees Celsius. The mixed raw materials are fed into a plastic extruder for extrusion, and the heating temperature of the plastic extruder ranges from 290 to 300 degrees Celsius. The extruder applies the casting method to extrude the mixture in the molten state to the T-shaped die t...

Embodiment 2

[0059] A selects polyphenylene sulfide (PPS), purchased from Chevron Phillips Chemical Company's Ryton series QA200N.

[0060] B selected Lithium Chloride (LiCl), purchased from Sigma Aldrich.

[0061] C selection fatty acid monoethanolamide was purchased from PHOENIX CHEMICAL, INC.

[0062] Preparation method: process 10.8 kg of raw material A, 3 kg of raw material B, and 0.4 kg of raw material C according to the same method as in Example 1. The heating temperature of the extruder is 310 degrees Celsius, and processed into a 50-micron brown opaque film. The conductivity of the film at room temperature (20 degrees Celsius) is 3.1×10 -4 S / cm, the tensile strength is 58.4MPa, the combustion limit oxygen index is 39, and the flame retardancy reaches the UL94V-0 level.

Embodiment 3

[0064] A selects polyphenylene sulfide (PPS), purchased from Chevron Phillips Chemical Company's Ryton series QA200N.

[0065] B selected Lithium Chloride (LiCl), purchased from Sigma Aldrich.

[0066] C is not added.

[0067] Preparation method: 10.8 kg of raw material A and 3 kg of raw material B were processed according to the method in Example 2, and the temperature of the extruder was 310 degrees Celsius, and processed into a 50-micron brown opaque film. The conductivity of the film at room temperature (20 degrees Celsius) is 5×10 -5 S / cm, the tensile strength is 57.8MPa, the combustion limit oxygen index is 39, and the flame retardancy reaches the UL94V-0 level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com