Laser photovoltaic battery of upside-down mounting structure, and manufacturing method therefor

A technology of laser photovoltaic cell and manufacturing method, applied in photovoltaic power generation, circuits, electrical components and other directions, can solve the problems of increasing series resistance, reducing battery performance, large sheet resistance, etc., reducing series resistance, improving heat dissipation performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Considering the many deficiencies in the existing technology, how to increase the parallel resistance, reduce the series resistance, increase the conversion efficiency of laser cells, and solve the corresponding production technology is of great significance.

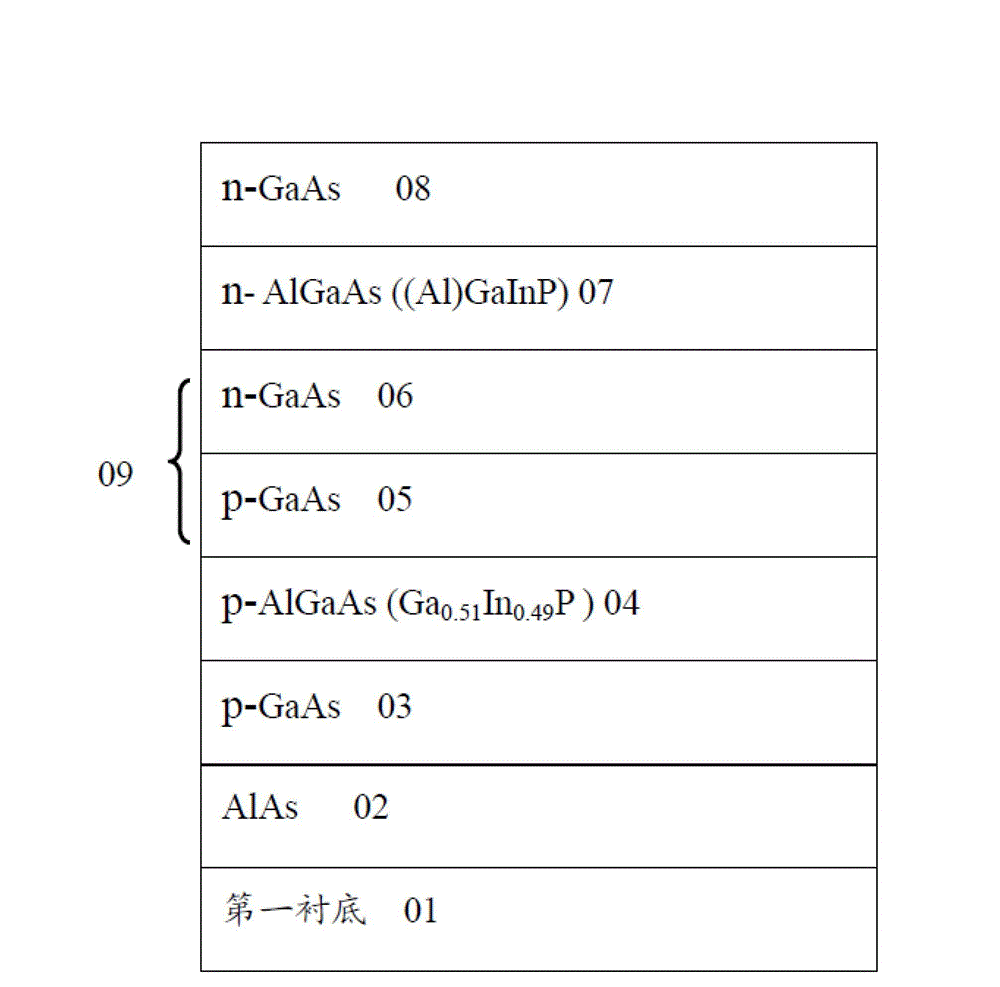

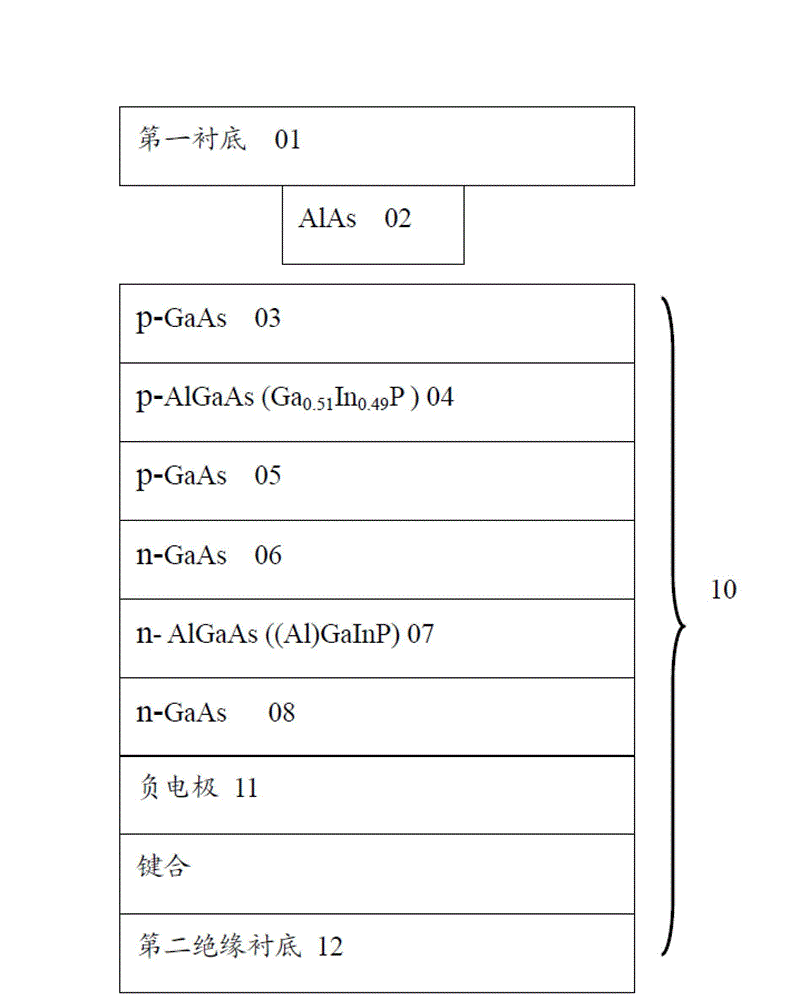

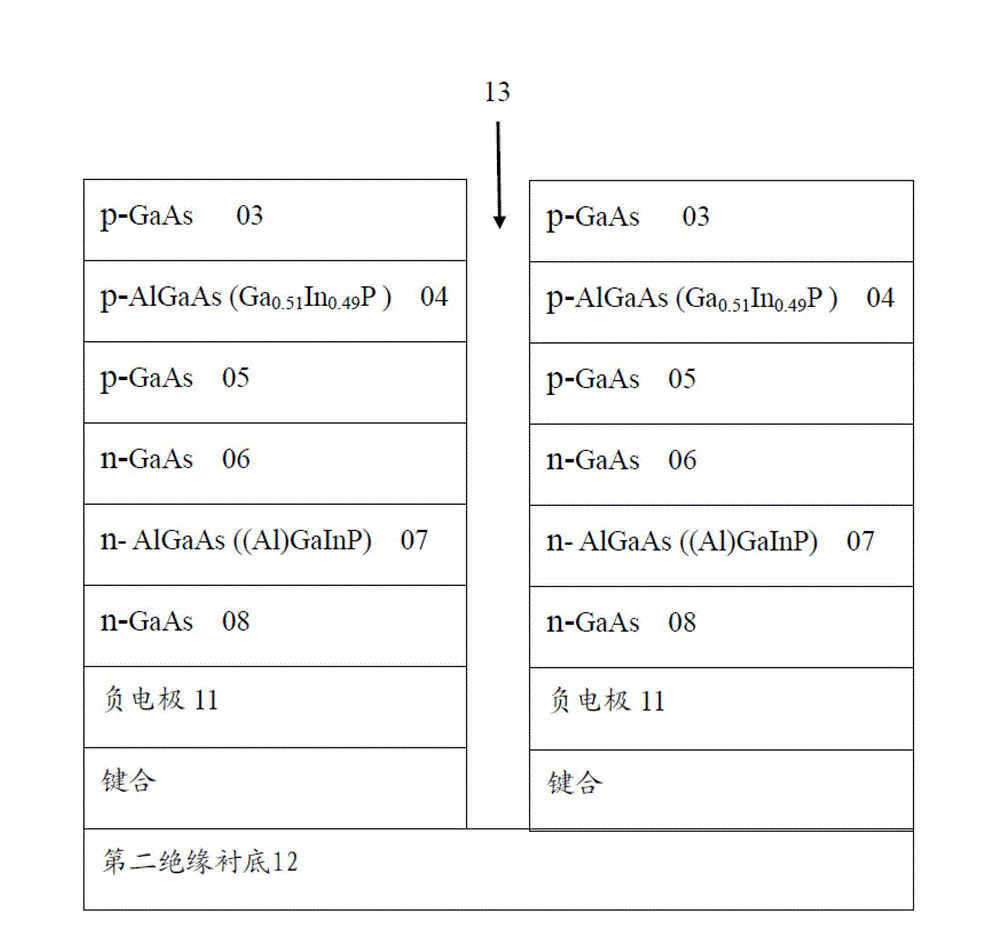

[0041] The embodiment of the present application discloses a laser photovoltaic cell with a flip-chip structure. The photovoltaic cell includes a second insulating substrate and an epitaxial layer on the second insulating substrate. The epitaxial layer includes Negative electrode, N-type conductive layer, P / N junction cell, P-type window layer and P-type contact layer on the second insulating substrate.

[0042] Correspondingly, the present application also discloses a fabrication method of a flip-chip laser photovoltaic cell, including:

[0043] (1) growing on the first substrate as a sacrificial layer for peeling off the first substrate;

[0044] (2) growing a P-type contact layer on the above sacrificial laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com