Numerical control machine tool production information obtaining method

A technology for producing information and CNC machine tools, which is applied in data processing applications, structured data retrieval, electrical digital data processing, etc. Comprehensive, scalable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

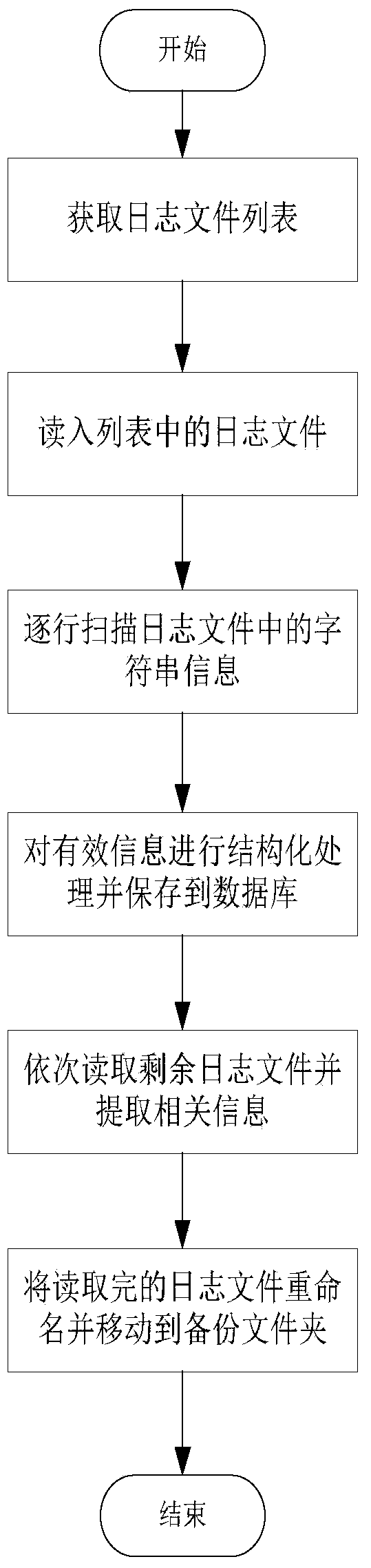

[0037] combine figure 2 , taking the production information management of a CNC laser cutting machine tool as an example, the machine tool uses the famous German Global Control CNC system:

[0038] First prepare the log reading module, which is developed in C# language, and the processing object is the log file generated by the operation of the Global Control CNC system. The log is in text format, and the log fragment example is as follows:

[0039]

[0040]

[0041]

[0042]Since the log record is very long, a random section is intercepted here as an example. It can be seen that the log file uses text as a record unit, and each line consists of three parts. The first part at the beginning is a timestamp, such as "2011-04-22_19-14-12", which means April 22, 2011 at 19:14 Minutes and 12 seconds, the second part is the status code, such as "1213", "1211", "138", "302", etc., and the third part is the status information, such as "X=0.0Y=0.0", "S:0 ", "Part-Cut-Length / ...

Embodiment 2

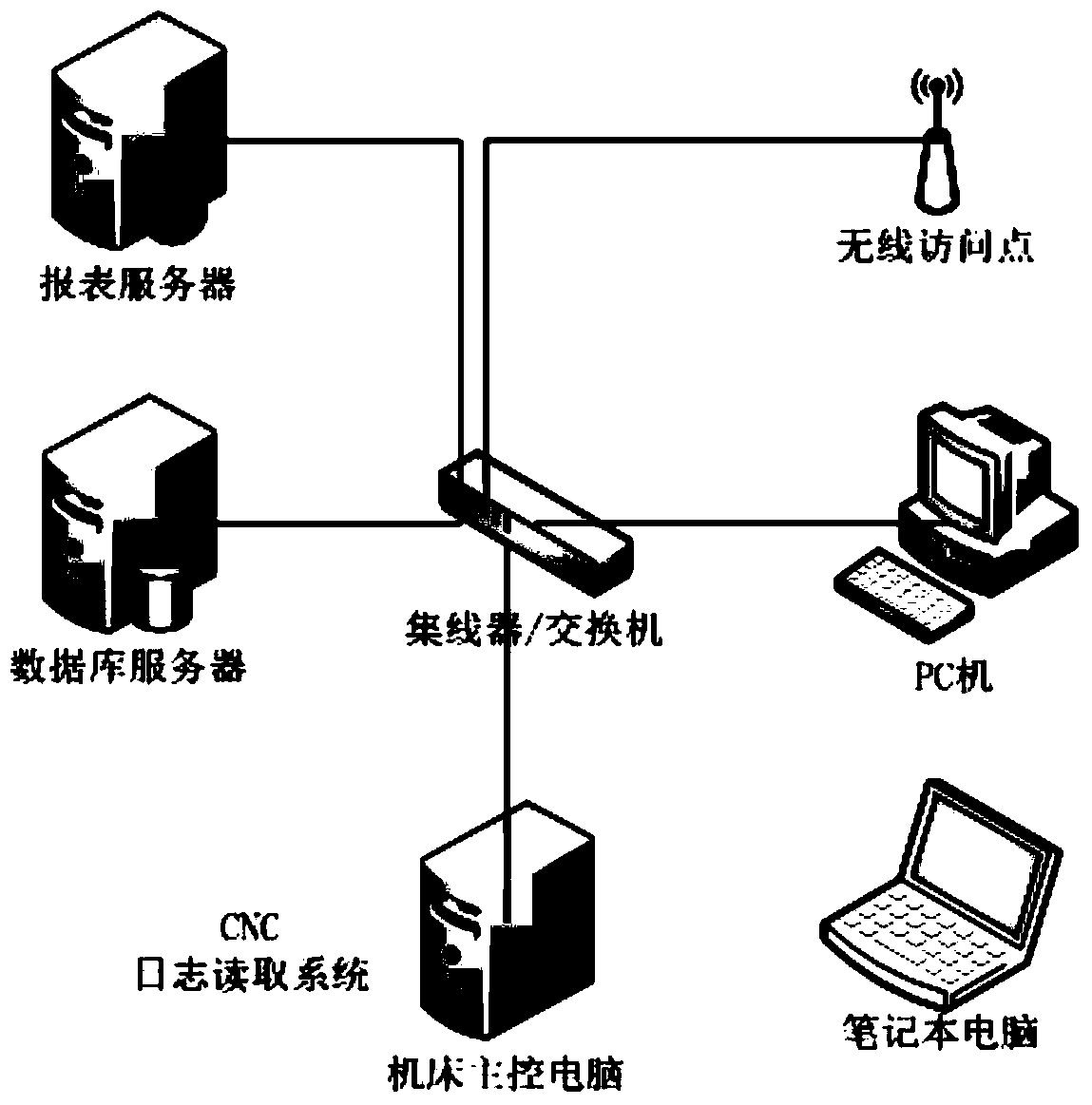

[0056] Manage production information of multiple CNC machine tools. When the present invention is used to manage multiple CNC machine tools, the method and steps are the same as in Embodiment 1, only the main control computers of all CNC machine tools need to be installed with a log reading system and connected to the workshop LAN, and the management of all machine tools is shared. The database server and the report module use the CNC machine number to distinguish different machine tools in the database table, and the log reading module uploads the machine tool number at the same time when uploading the respective machine data. In this way, statistics of production information by machine number can be realized in the report module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com