Large-temperature-difference efficient heat supply system of gas-fired boiler

A gas-fired boiler and heating system technology applied in the energy field to achieve long-distance efficient heating, eliminate winter smog, and improve energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

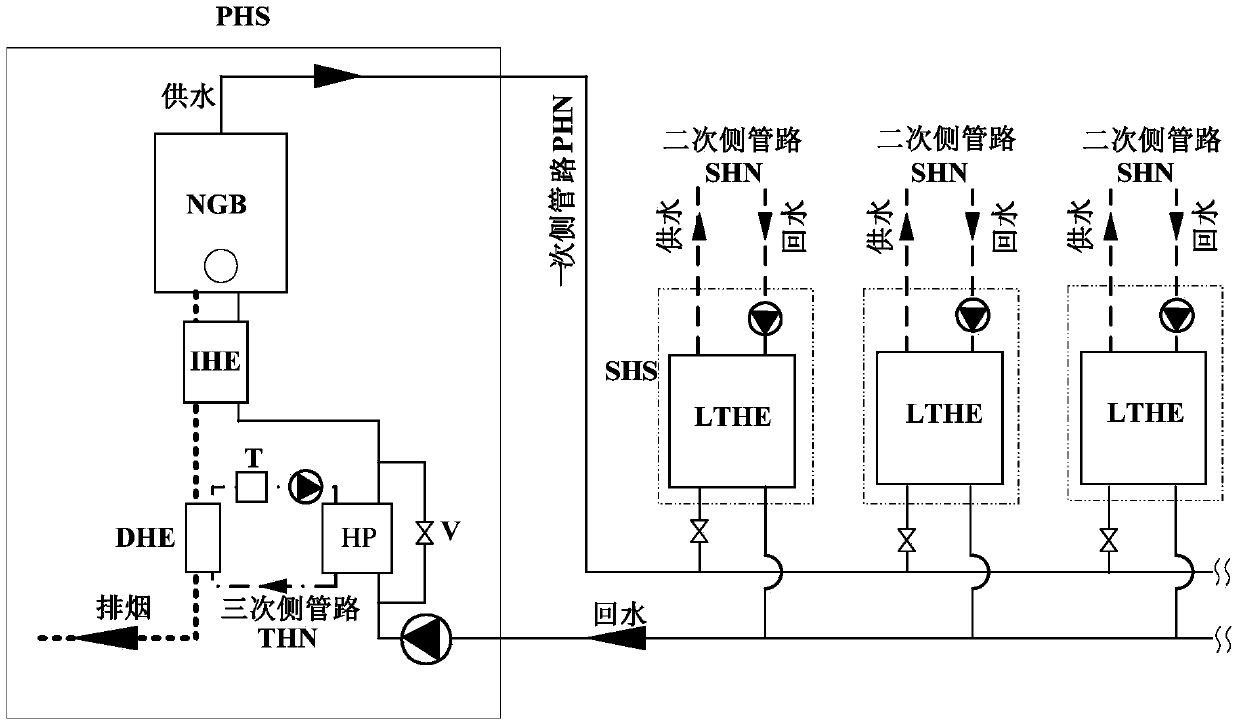

Embodiment 1

[0041] Such as figure 1 As shown, the large temperature difference high-efficiency heating system of the gas boiler of the present invention is composed of the first heating station PHS, the primary side pipeline PHN, the heat station SHS, the secondary side pipeline SHN, the tertiary side pipeline THN and other accessories. Among them, the first heating station PHS is composed of gas boiler NGB, partition wall heat exchanger IHE, contact heat exchanger DHE, heat pump HP, circulation pump, connecting pipelines and other accessories, and the thermal station is composed of large temperature difference heat exchange unit LTHE, Circulation pump, connecting pipeline and other accessories.

[0042] The flue gas from the gas-fired boiler enters the partition heat exchanger IHE and the contact heat exchanger DHE in turn to be cooled down, and then is discharged into the atmosphere through the chimney.

[0043] When the unit is running, the primary side high-temperature heat medium pr...

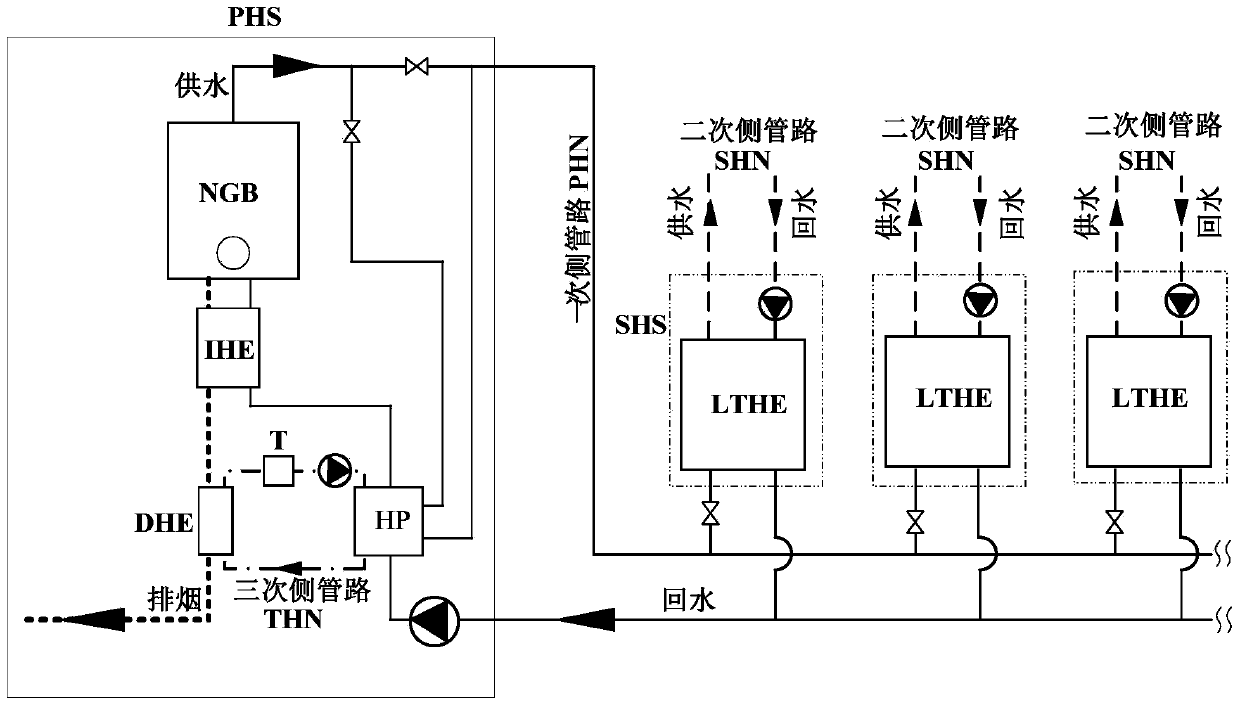

Embodiment 2

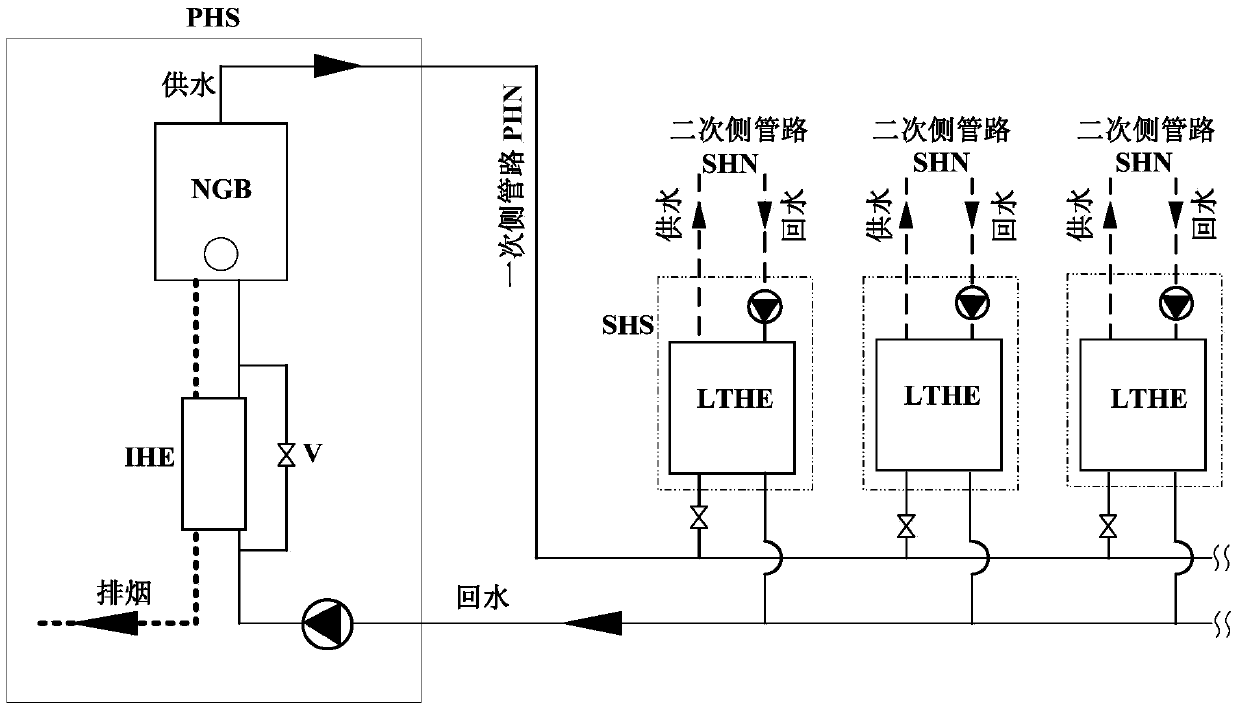

[0048] Such as image 3 As shown, the gas-fired boiler large temperature difference high-efficiency heating system of the present invention is composed of the first heating station PHS, the primary side pipeline PHN, the heat station SHS, the secondary side pipeline SHN and other accessories. Among them, the first heating station PHS is composed of gas boiler NGB, partition wall heat exchanger IHE, circulation pump, connecting pipeline and other accessories, and the thermal station is composed of large temperature difference heat exchange unit LTHE, circulation pump, connecting pipeline and other accessories .

[0049] When the unit is running, the primary side high-temperature heat medium process: the primary side high-temperature heat medium from the first heating station PHS is transported and distributed to each heat station SHS through the primary side pipeline PHN, and is transferred to the secondary side in the large temperature difference heat exchange unit LTHE. Afte...

Embodiment 3

[0052] The large temperature difference heat exchange unit can adopt, adsorption heat exchange unit, compression heat exchange unit, jet heat exchange unit or absorption heat exchange unit.

[0053] Such as Figure 4 As shown, the compression heat exchange unit is composed of a compression heat pump CHP and a water-water heat exchanger WHE. The high-temperature water supply on the primary side enters the water-water heat exchanger WHE and the evaporator E of the compression heat pump CHP in turn to realize heat release step by step. , cooling; the secondary side return water or respectively enters the water-water heat exchanger WHE, and the condenser C of the compression heat pump CHP is heated up.

[0054] Such as Figure 5 As shown, the compression heat exchange unit is composed of two compression heat pumps CHP and a water-to-water heat exchanger WHE. The high-temperature water supply on the primary side enters the water-to-water heat exchanger WHE, the evaporators E1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com