Ceramic brick with color-changing enamel layer, green body structure and production method of ceramic brick

A production method and technology for ceramic tiles, applied in building construction, covering/lining, construction, etc., can solve problems such as unrealism and lingering effects, and achieve the effects of easier cleaning, brighter colors, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

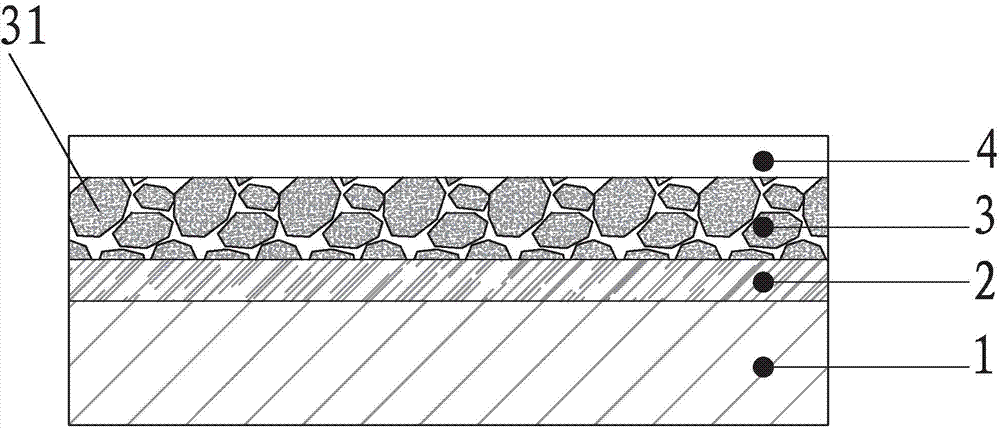

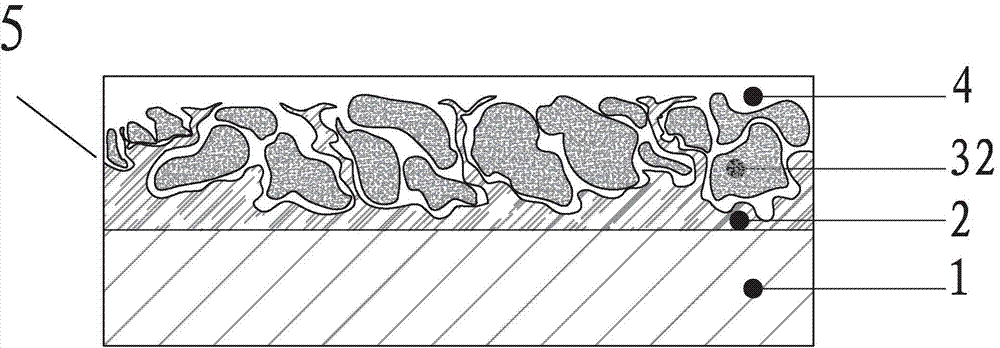

[0045] As shown in the accompanying drawings, a production method for ceramic tiles with changing glaze layers, the structure of the green ceramic tiles is composed of a bottom body 1, a bottom glaze 2, a colored particle layer 3 and a transparent surface glaze layer 4.

[0046] The colored granules in the colored granule layer are pre-calcined from regenerated raw ore, and the particle size is preferably between 12 mesh and 40 mesh sieve. The weight ratio of raw materials is: 20% potassium feldspar; 10% quartz; 10% zinc oxide; 5% lithium carbonate; 2% chromium carbonate; 10% titanium oxide; 1% manganese oxide; 20% kaolin; 17% barium carbonate; Copper acetate 5%.

[0047] The water content of the bottom body powder accounts for 6.5% of the mass of the body powder, and the fineness of the body powder is 1.0% over a 250-mesh sieve; the fineness of the transparent glaze slurry in the transparent surface glaze layer is 0.6% over a 325-mesh sieve .

[0048] The powder of the bott...

Embodiment 2

[0050] As shown in the accompanying drawing, a production method of ceramic tiles with changing color glaze layer, the structure of the green ceramic tile is composed of bottom body 1, bottom glaze 2, colored particle layer 3 and transparent surface glaze layer 4.

[0051]The colored granules in the colored granule layer are pre-calcined from regenerated raw ore, and the particle size is preferably between 12 mesh and 40 mesh sieve. The weight ratio of raw materials is: potassium feldspar 15%; quartz 15%; zinc oxide 10%; lithium carbonate 4%; chromium carbonate 2%; titanium oxide 11%; manganese oxide 3%; kaolin 20%; barium carbonate 17%; Copper acetate 3%.

[0052] The water content of the bottom body powder accounts for 8.5% of the mass of the body powder, and the fineness of the body powder is 0.8% over a 250-mesh sieve; the fineness of the transparent glaze slurry in the transparent surface glaze layer is 0.4% over a 325-mesh sieve %.

[0053] The powder of the bottom bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com